Rectangular high and low frequency mixed connector assembly

A connector assembly, high and low frequency technology, applied in the installation of connecting parts, parts and connections of connecting devices, etc., can solve the problems of high and low frequency mixed connectors without anti-mis-insertion structure, non-replaceability of high and low frequency accessories, high Low-frequency mixed-installed connectors are scrapped and other issues, achieving the effects of short assembly time, reduced installation size, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

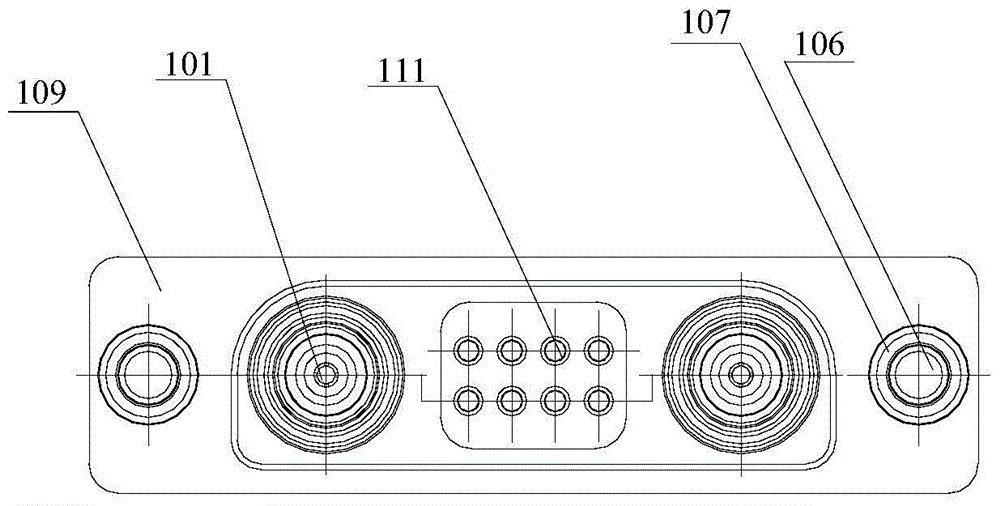

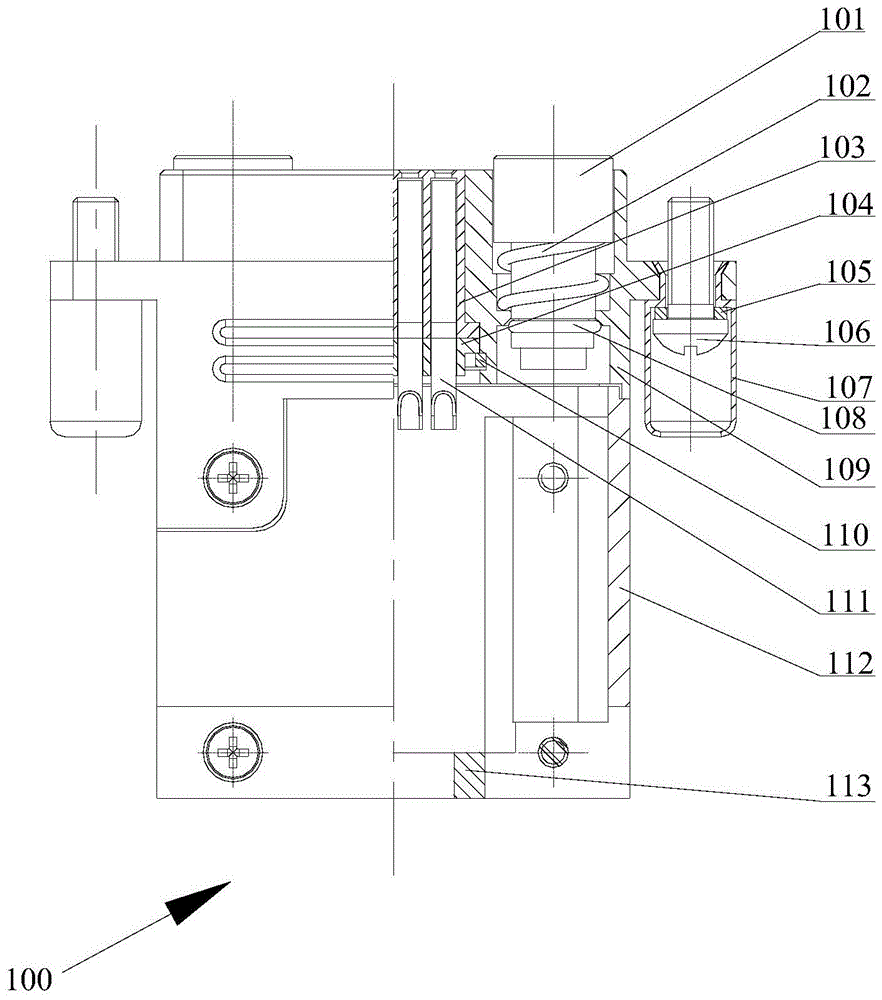

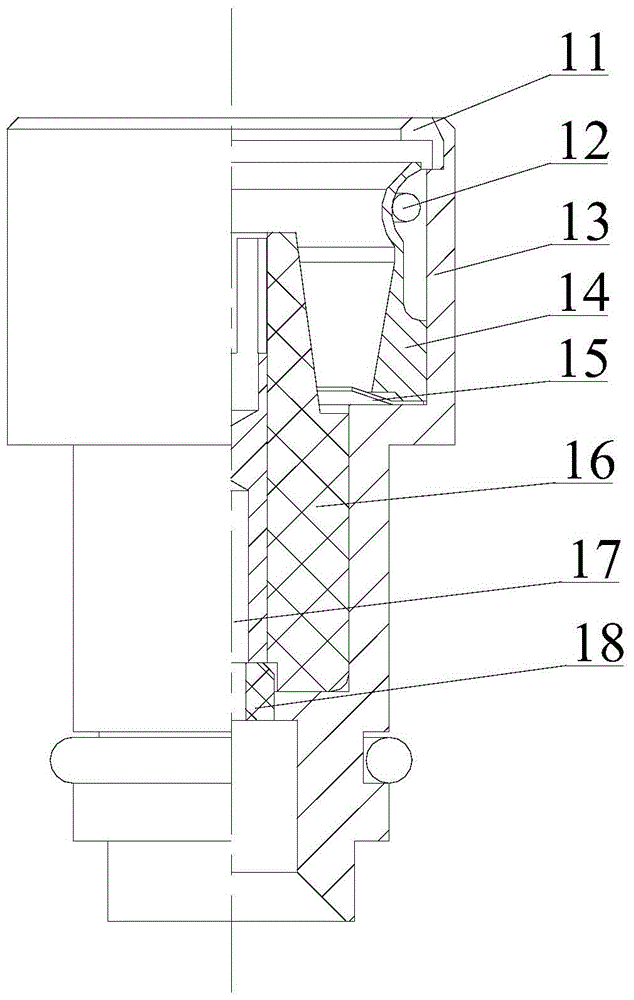

[0027] Rectangular high and low frequency mixed connector assemblies, such as Figure 1 to Figure 7 As shown, it includes a plug 100 and a socket 200. The plug 100 uses its front end as a plug-in terminal and includes a plug housing 109. The plug housing 109 is a rectangular aluminum alloy housing and has a high-frequency accessory installation hole and a low-frequency accessory installation hole. The high-frequency accessory mounting hole is equipped with a plug high-frequency accessory 101, and the plug high-frequency accessory 101 is composed of a high-frequency housing 13, a contact head 14, an insulator 16, an insulator 18 and a high-frequency jack contact 17, and a snap ring 12 Press into the contact head 14, the contact head 14 is welded in the high-frequency housing 13, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com