Mower

A lawnmower and grass-cutting technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problem of long length of grass, poor grass cutting effect of lawn mower, and inability to effectively use grass, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

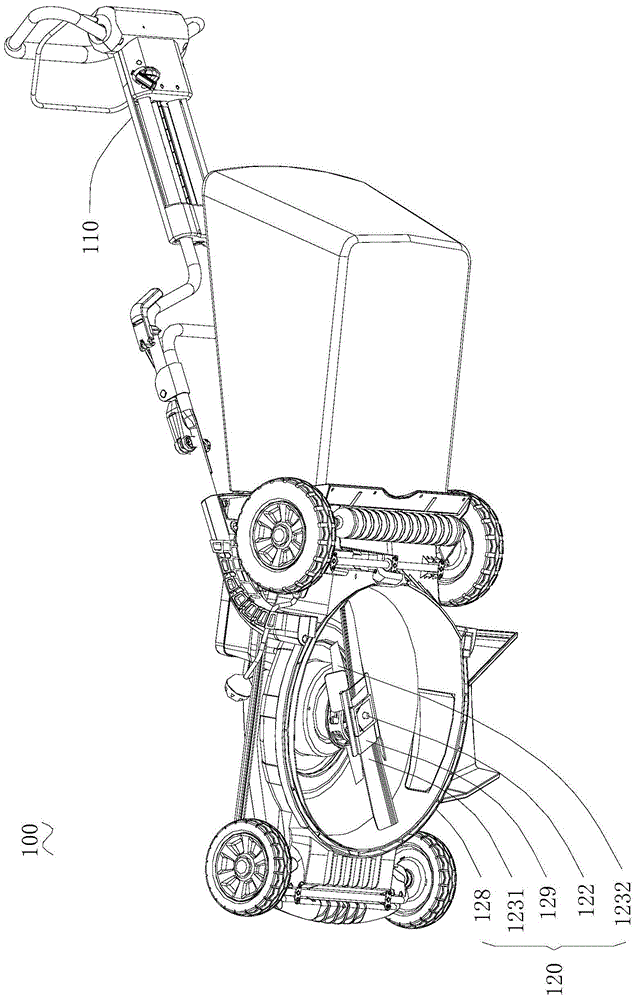

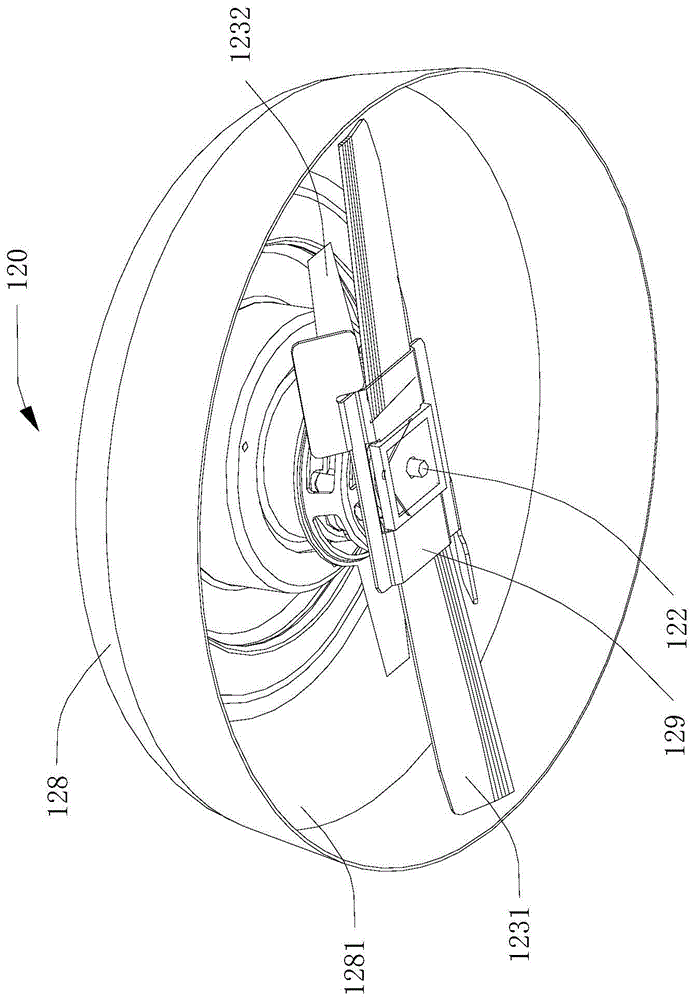

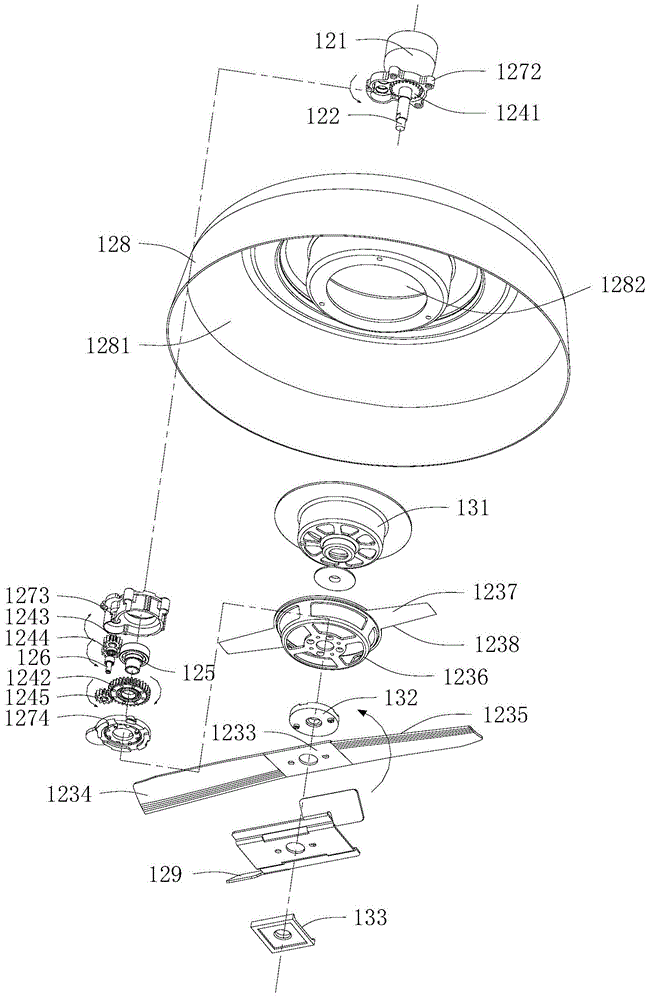

[0032] Please refer to figure 1 , figure 1 Shown is a three-dimensional structure diagram of the lawn mower 100 in this embodiment, which includes a main body 110 of the lawn mower and a mowing mechanism 120 arranged at the bottom of the main body 110 of the lawn mower. Please refer to figure 2 , The mowing mechanism 120 includes a driving motor 121 , a driving shaft 122 mounted on the driving motor 121 and a cutting blade 123 connected to the driving shaft 122 . The cutting blade 123 includes a first cutting blade 1231 and a second cutting blade 1232 disposed between the first cutting blade 1321 and the driving motor 121 . Compared with the single-layer cutting blade of a traditional lawnmower, the mowing mechanism 120 in this embodiment has an additional layer of cutting blades. When the drive motor drives the double-layer cutting blades to run, the first cutting blade and the second cutting blade can rotate in the same direction or in the opposite direction, and deeply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com