The working method of tea picking manipulator

A working method and manipulator technology, applied in picking machines, agricultural machinery and implements, harvesters, etc., can solve problems such as large range of motion, reduced tea output, limited cutting force, etc., to improve conveying efficiency, improve picking efficiency, The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

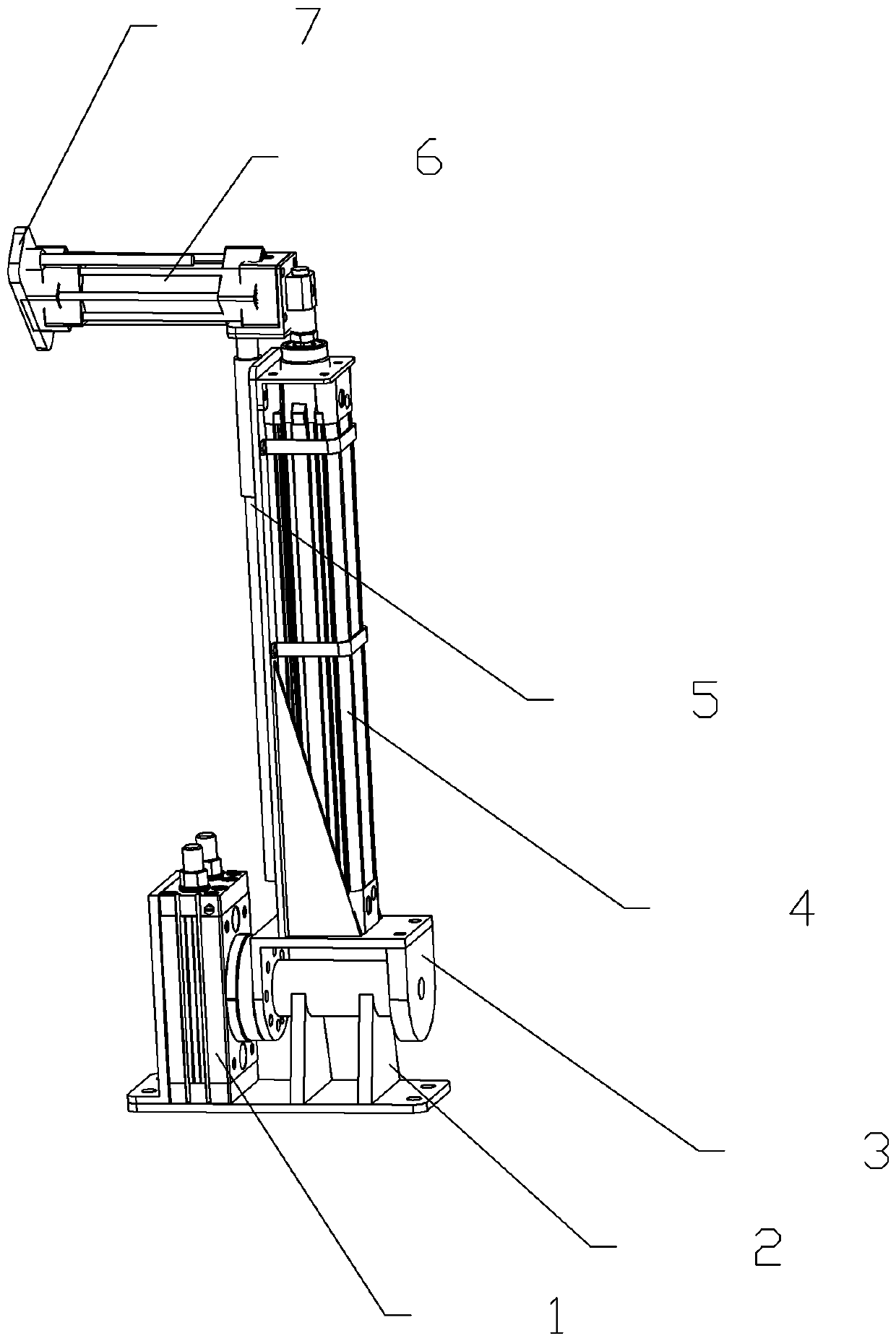

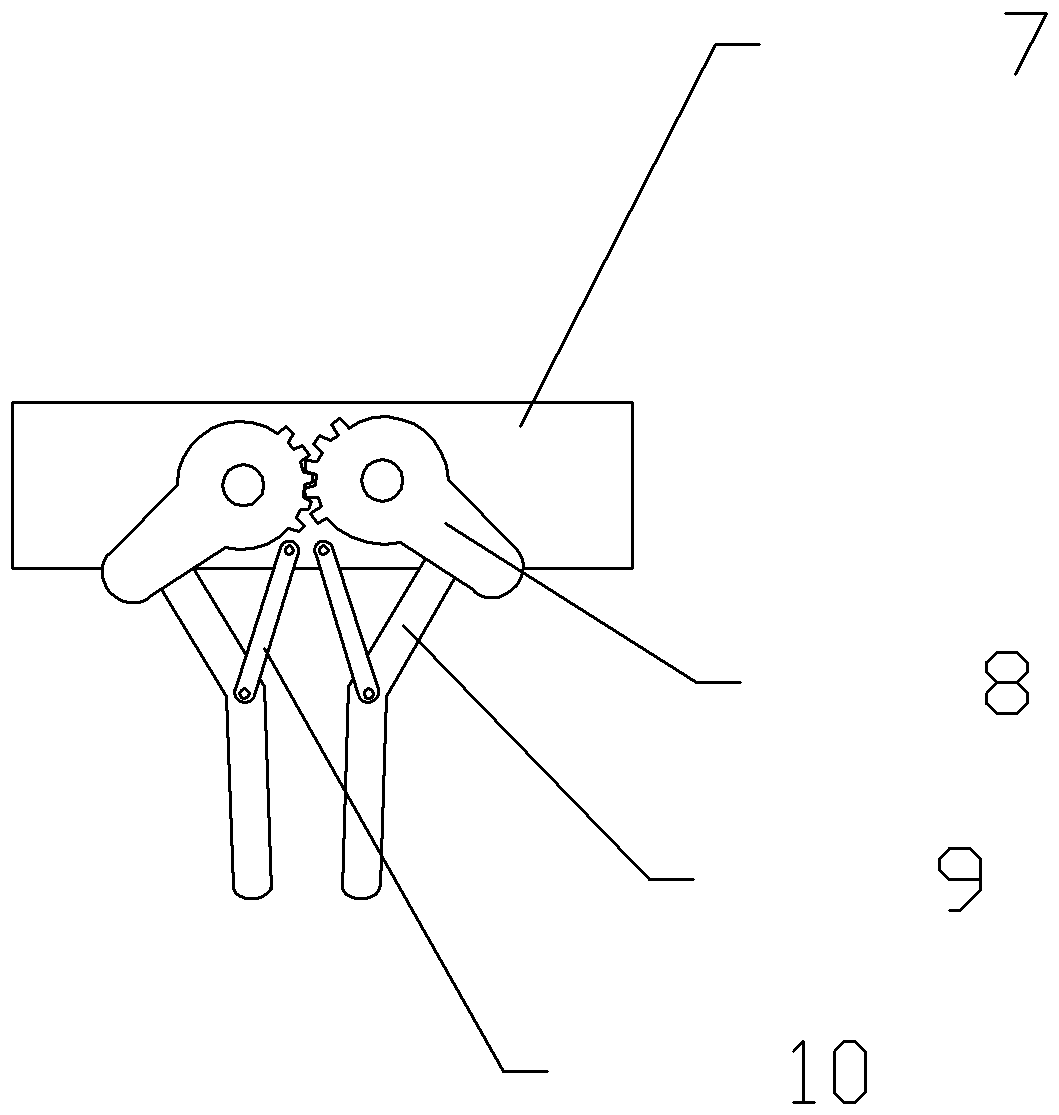

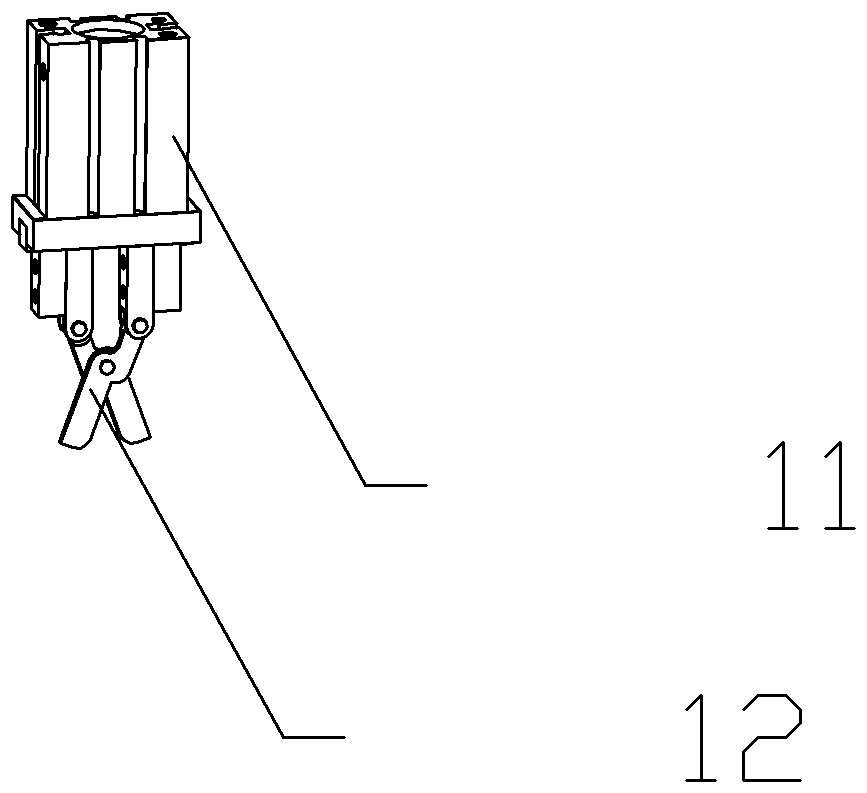

[0023] The reference signs in the accompanying drawings of the description include: rotating cylinder 1, support plate 2, U-shaped connecting seat 3, vertical telescopic cylinder 4, guide rod 5, horizontal telescopic cylinder 6, connection plate 7, crank 8, swing rod 9, Connecting rod 10, two-way cylinder 11, scissors hand 12.

[0024] as attached figure 1 In the shown tea-picking manipulator, the lower part of the first vertical mounting plate is welded with a horizontal support seat, and the first vertical mounting plate is provided with a vertical rotating cylinder, and the rotating shaft of the rotating cylinder extends out of the rotating cylinder and is set horizontally. A sleeve is provided outside the shaft. There are two support plates fixed on the support base and arranged symmetrically with the vertical center line of the rotating shaft, so that the sleeve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com