A kind of straw feeding chopping and throwing device

A technology of throwing device and straw, which is applied to cutters, crop processors, agricultural machinery and implements, etc., can solve problems such as utilization defects of stubble straw, and achieve the effects of improving growth effect, increasing crop yield and high operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

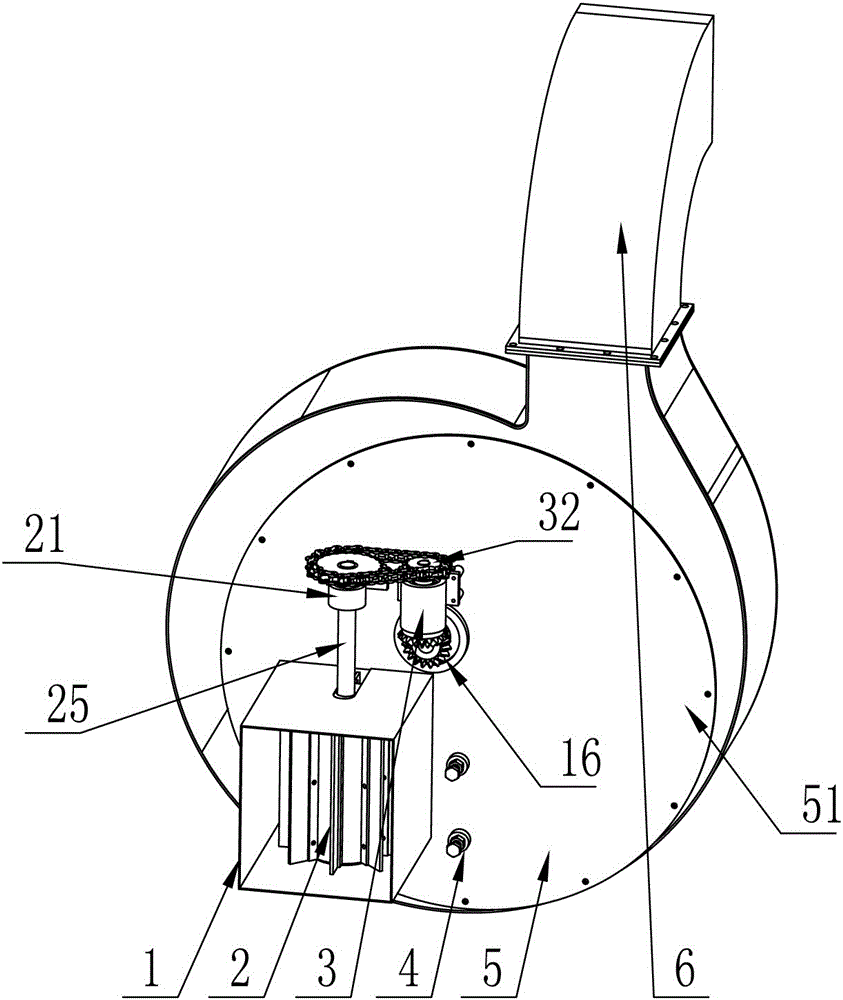

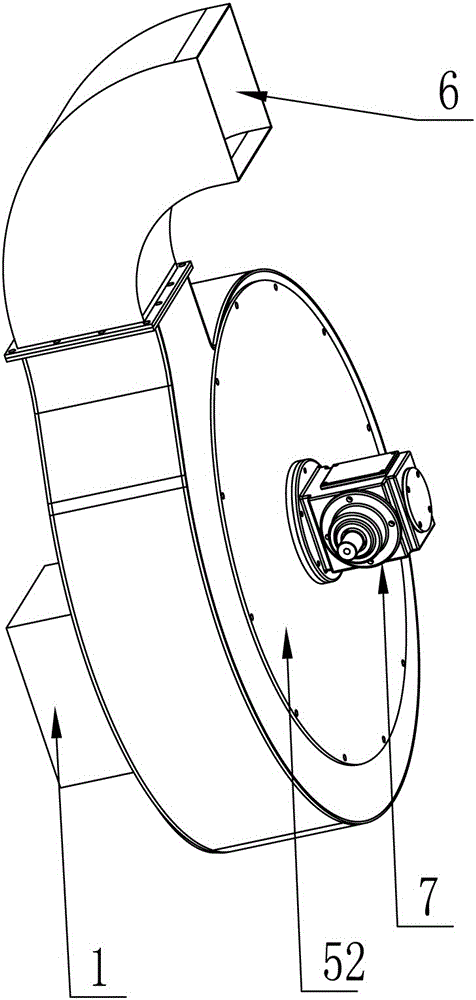

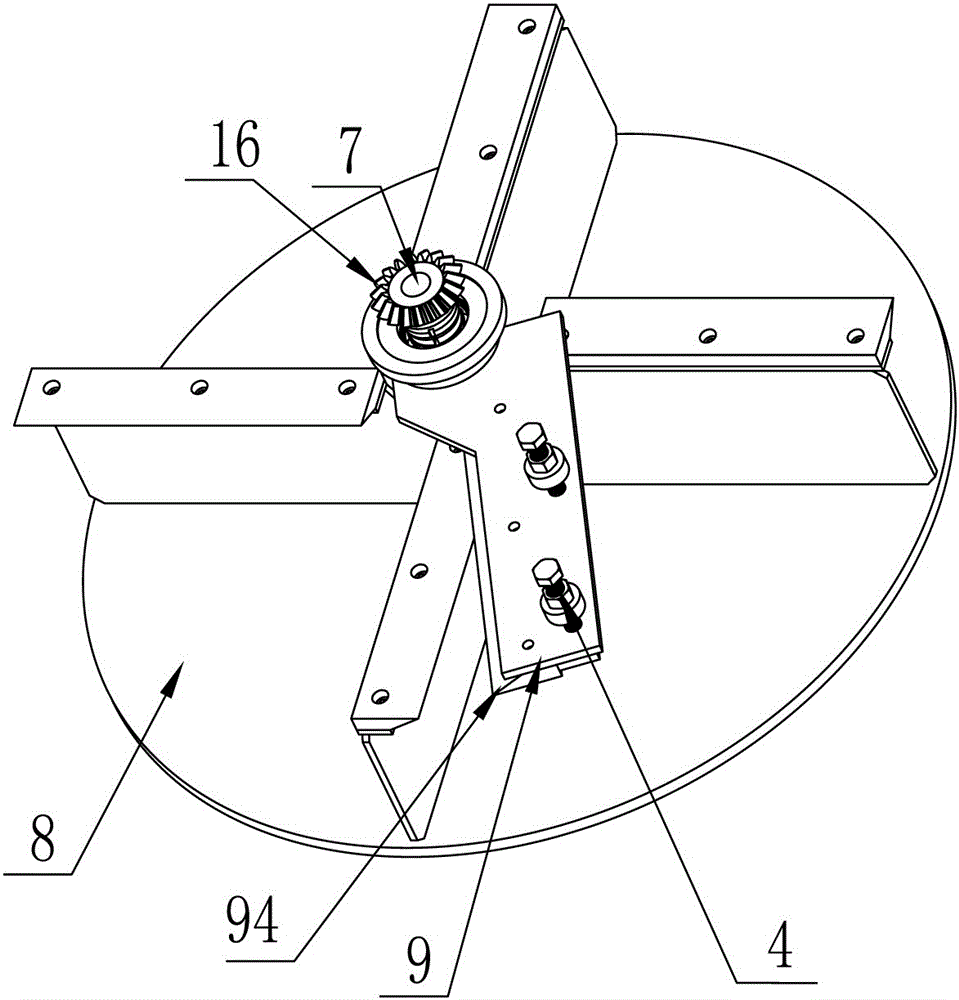

[0030] refer to Figure 1-Figure 9 As shown, the stalk feeding, chopping and throwing device of the present invention includes a fan housing 5, which forms a closed cavity by a front end plate 51 and a rear end plate 52, and a throwing fan housing 5 is also provided at the upper end of the fan housing 5. Port 6, the fan housing 5 is preferably designed with an Archimedes spiral. The outside of the front end plate 51 of the fan casing 5 is provided with a feeding inlet 1, which is provided with a rolling grass conveying device 2, and the feeding inlet 1 is connected with the inside of the fan casing; The rear end plate 52 of 5 penetrates into the fan housing 5, and extends out of the front end plate 51 of the fan housing 5; the fan shaft 10 located in the fan housing 5 is provided with a moving knife part 8 and a fixed knife part 9, the moving knife part 8 Knife part 8 comprises the fan blade 85 that is fixed on fan shaft 10 and moving knife 83, and this fixed knife part 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com