Straw chopping and wind blowing directional throwing device

A technology of spreading device and air delivery, which is applied in the direction of cutters, crop processors, agricultural machinery and implements, etc., to achieve the effects of easy processing, high operating efficiency, and increased crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

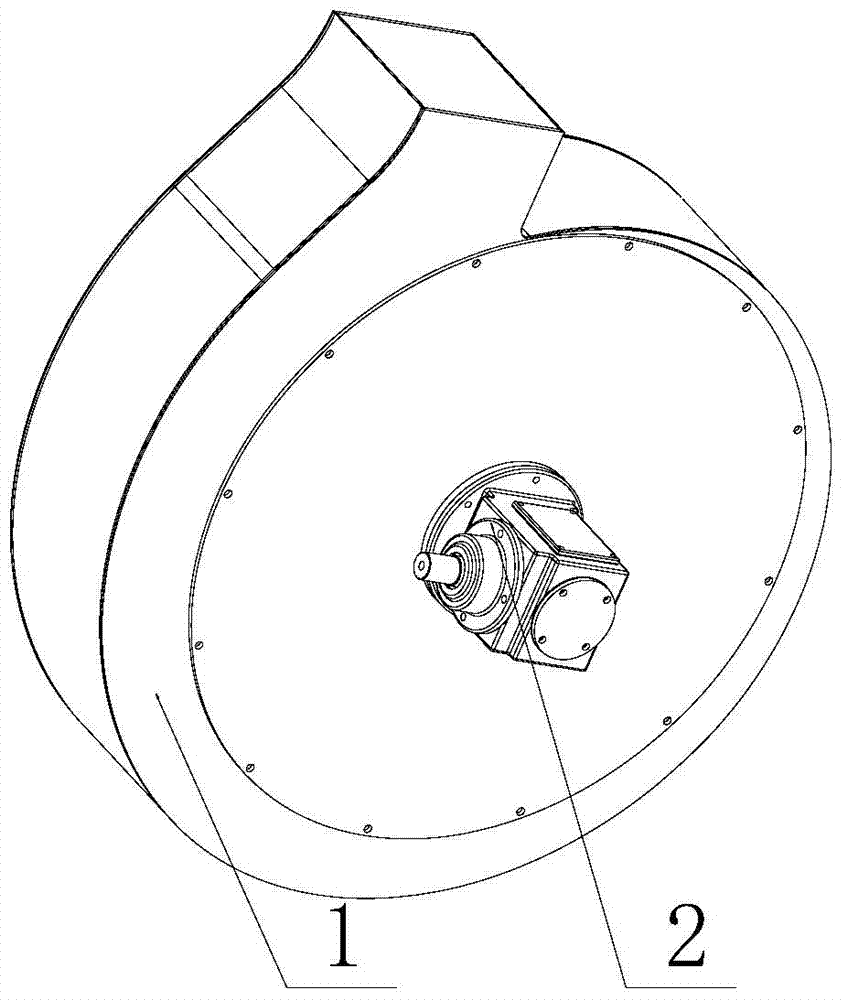

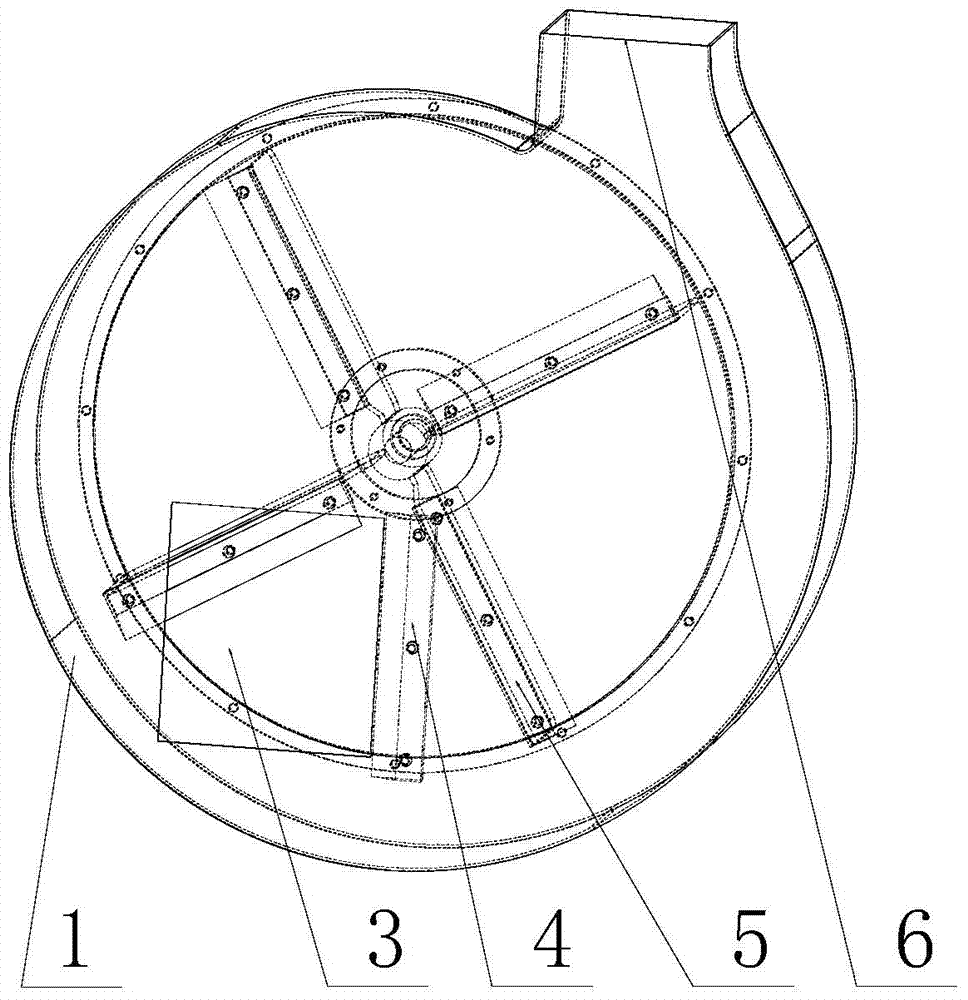

[0027] see figure 1 with figure 2 , the straw chopping and air blowing directional throwing device, including a casing 1, a fixed knife 4, a moving knife assembly 5 and an air blowing directional throwing device 8, the side of the casing 1 is provided with a feeding port 3 for feeding straw, and the fixed knife 4. It is arranged inside the casing 1 on the edge of the feeding port 3. The moving knife assembly 5 includes a fan blade 55 and a moving knife 53. The moving knife 53 is fixed on the side of the rotating fan blade and performs shearing motion with the fixed knife 4. The position of the air outlet of the fan blade on the casing 1 is provided with a throwing port 6 , and the air blowing directional throwing device 8 is docked with the throwing port 6 .

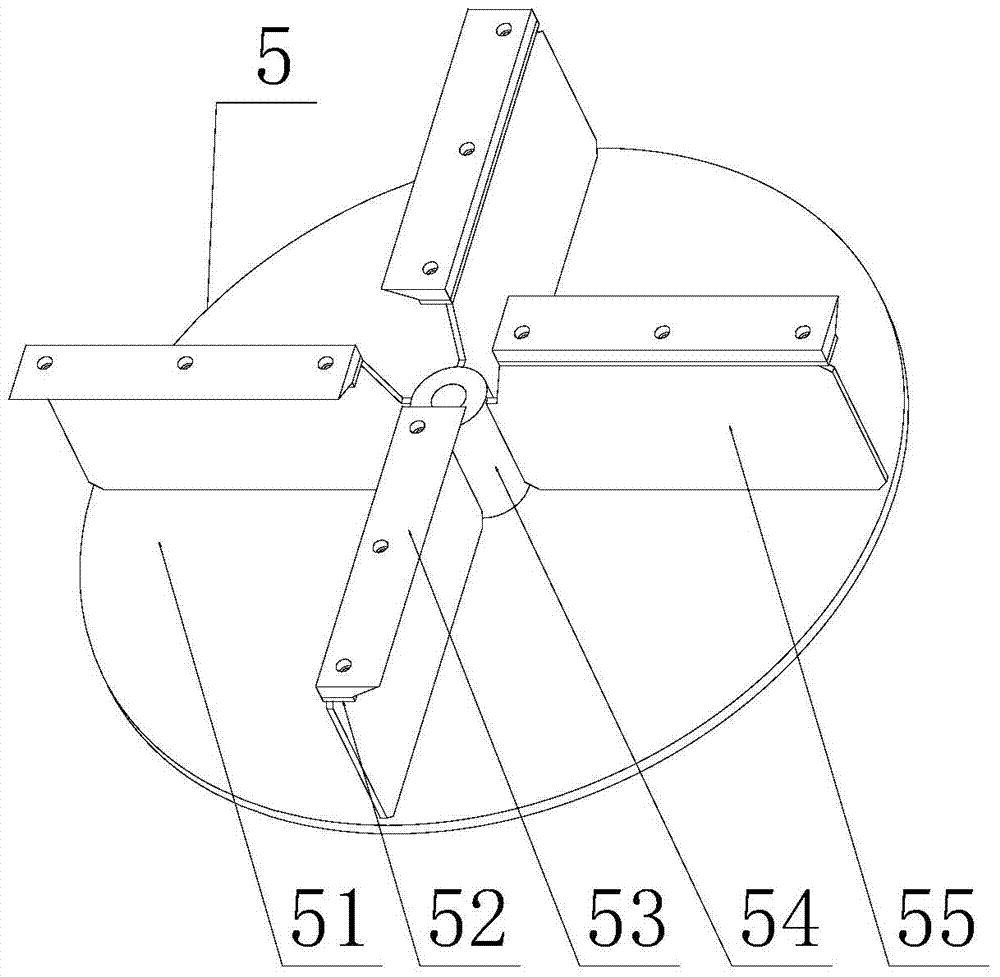

[0028] see further image 3 , Figure 4 with Figure 5 , the four blades 55 are vertically fixed and welded on the fan flange 51 with the fan shaft sleeve 54 as the center, the casing 1 is provided with a transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com