Skin care product containing snail slime and preparation method of skin care product

A snail mucus and product technology, which is applied in the field of skin care products, can solve the problems of low safety, affect economic benefits, reduce users' desire for consumption, etc., and achieve the effects of high safety, improved economic benefits, and good repairing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] A preparation method of a skin care product containing snail mucus, comprising the following steps:

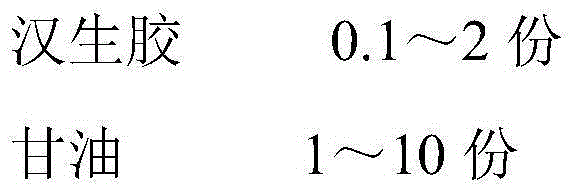

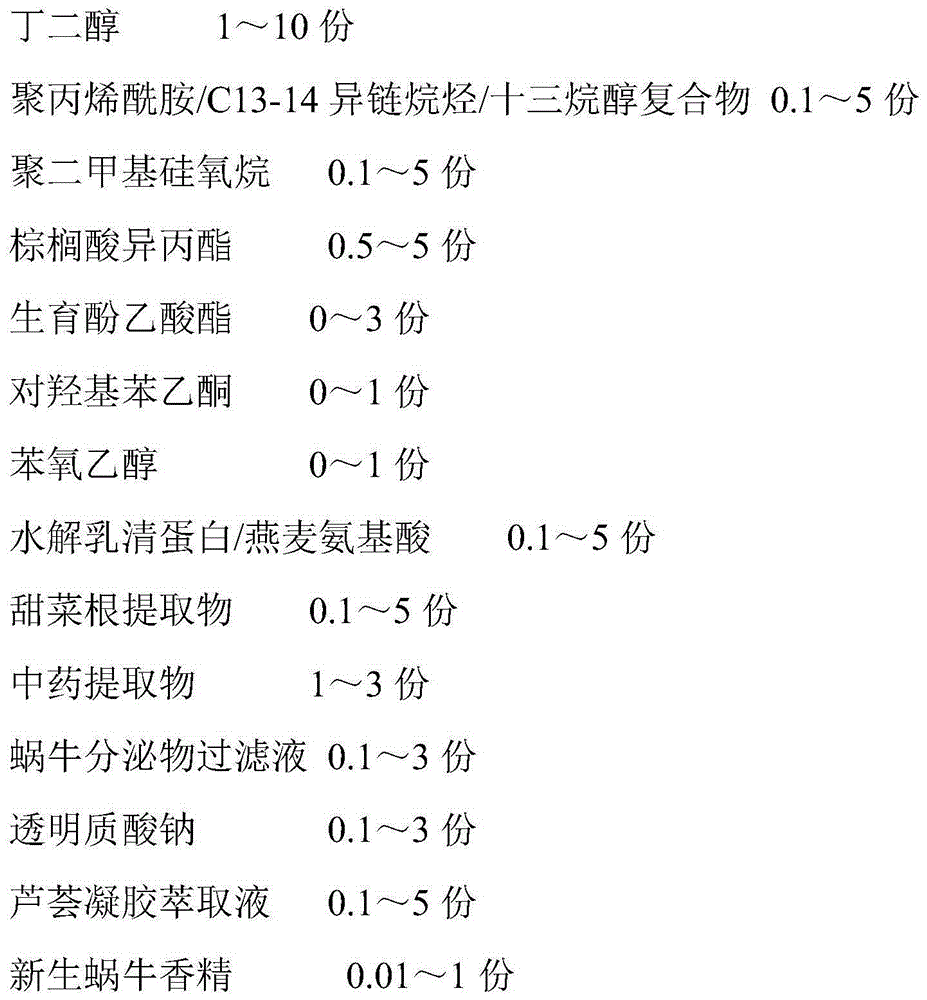

[0035] S1: Add pure water or mineral water into the emulsifying pot, add 0.1-2 parts of xanthan gum in stages, and add 0.1-0.2 parts each time. After each addition, the stirring speed is 200- Homogenize for 3 to 5 minutes at 300 rpm, then heat up to 72 to 78°C at a stirring speed of 800 to 1000 rpm, keep stirring for 5 to 15 minutes, add 1 to 10 parts of glycerol, 1 to 10 10 parts of butanediol and 0.1 to 5 parts of polyacrylamide / C13-14 isoparaffin / tridecanol compound are mixed uniformly to obtain a first mixed solution.

[0036] S2: add 0.1-5 parts of polydimethylsiloxane and 0.5-5 parts of isopropyl palmitate into the reaction vessel, stir and heat up to 73-80° C., keep stirring for 10-20 min to obtain a second mixed solution.

[0037] S3: the emulsification pot is evacuated to the condition that the vacuum degree is -0.04Mpa~-0.06Mpa, the second mixed solution is a...

Example Embodiment

[0042] Example 1

[0043]Add pure water or mineral water into the emulsification pot, add 2 parts of xanthan gum into the emulsification pot in batches, each addition is 0.2 part, and the stirring speed is 200 rpm after each addition. Homogenize for 3min, then heat up to 78°C under the condition that the stirring speed is 100 rpm, keep stirring for 15min, add 5 parts of glycerol, 7 parts of butanediol and 5 parts of polyacrylamide / C13-14 isoparaffin / thirteen The alkanol complex is stirred uniformly to obtain the first mixed solution.

[0044] 0.1 part of polydimethylsiloxane and 0.5 part of isopropyl palmitate were added to the reaction vessel, and the temperature was raised to 80° C. with stirring, and the temperature was maintained and stirred for 20 minutes to obtain a second mixed solution.

[0045] The emulsifying pot was evacuated to the condition that the vacuum degree was -0.06Mpa, the second mixed solution was added to the first mixed solution, and after mixing evenl...

Example Embodiment

[0047] Example 2

[0048] Add pure water or mineral water into the emulsification pot, add 1 part of xanthan gum into the emulsification pot in batches, each addition is 0.1 part, and the stirring speed is 200 rpm after each addition. Homogenize for 4min, then heat up to 72°C under the condition of stirring speed of 800 rpm, keep stirring for 5min, add 1 part of glycerol, 1 part of butanediol and 5 parts of polyacrylamide / C13-14 isoparaffin / thirteen The alkanol complex is stirred uniformly to obtain the first mixed solution.

[0049] 5 parts of polydimethylsiloxane and 5 parts of isopropyl palmitate were added to the reaction vessel, and the temperature was raised to 75° C. with stirring, and kept stirring for 15 minutes to obtain a second mixed solution.

[0050] The emulsifying pot is evacuated to the condition that the vacuum degree is -0.06Mpa, the second mixed solution is added to the first mixed solution, and after mixing evenly under the condition of temperature of 72 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com