C-shaped flanging metal rubber component preparation process

A metal rubber and preparation technology, applied in metal processing equipment, manufacturing tools, forming tools, etc., to achieve stable performance, long service life, and vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

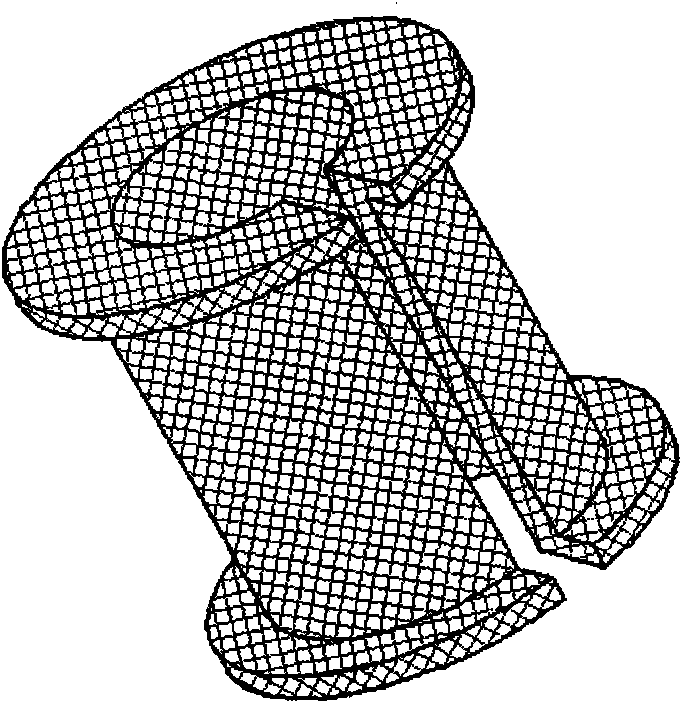

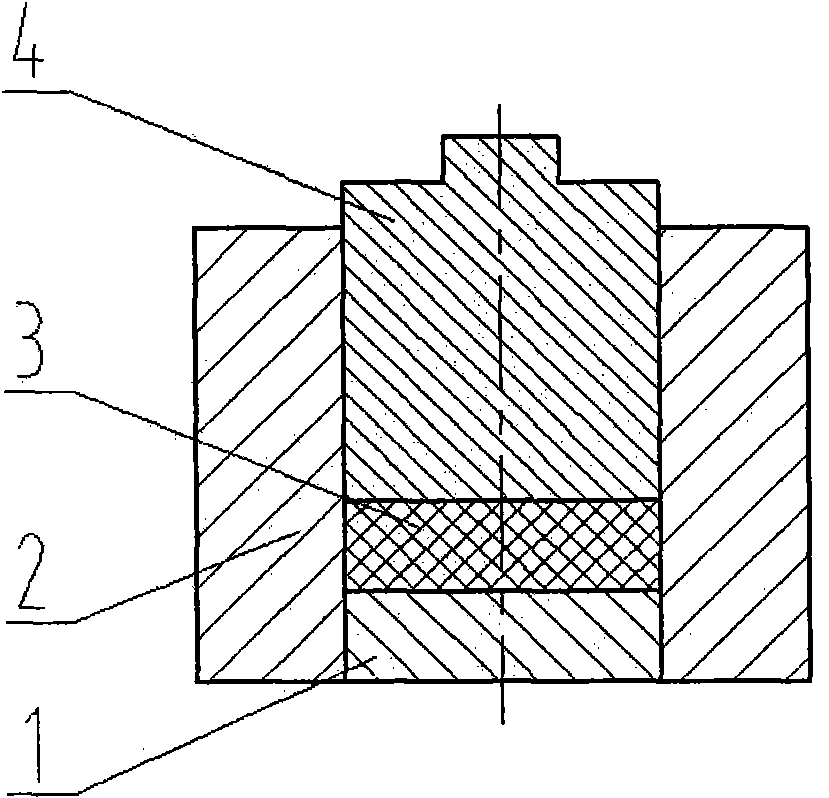

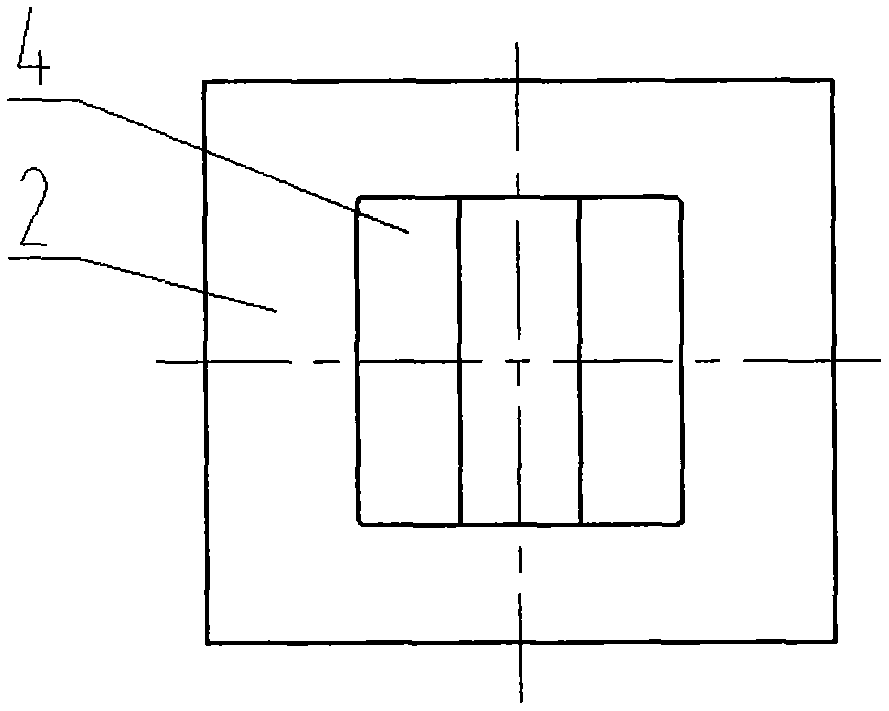

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] The process method for preparing the C-shaped flanging metal rubber component comprises the following steps:

[0030] The first step is to select the metal wire and use a special wire winding machine to wind it into a dense spiral coil;

[0031] According to the technical index requirements of the prepared metal rubber components, the material and diameter of the metal wire are selected, and the diameter range is 0.10-0.30mm. On December 25, 2013, the metal wire was wound into a dense helical coil, and the diameter of the helical coil was controlled to be 5 to 15 times the diameter of the metal wire, so as to ensure the gap between the helical coil turns inside the metal rubber member after forming. Good connection.

[0032] The second step is to prepare blanks by using CNC automatic metal rubber blank winding equipment;

[0033] For the CNC automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com