The method of edge pressing with electronically controlled permanent magnet technology

An electronically controlled permanent magnet and blank holder technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of complex composition and structure of the control system, inability to provide blank holder force control, high manufacturing cost and energy consumption, etc. To achieve the effects of compact structure, long-term stability, and improved quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

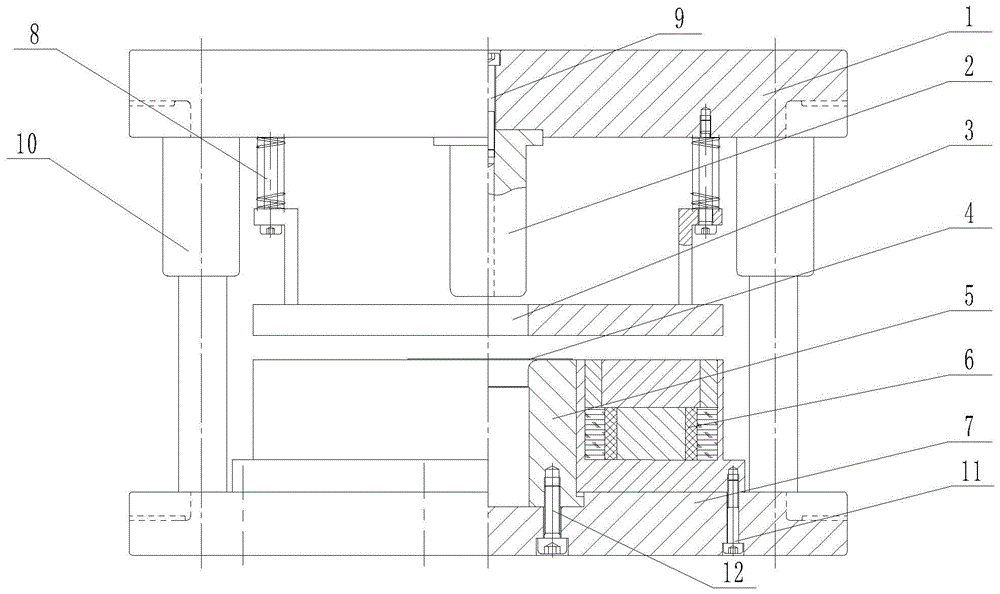

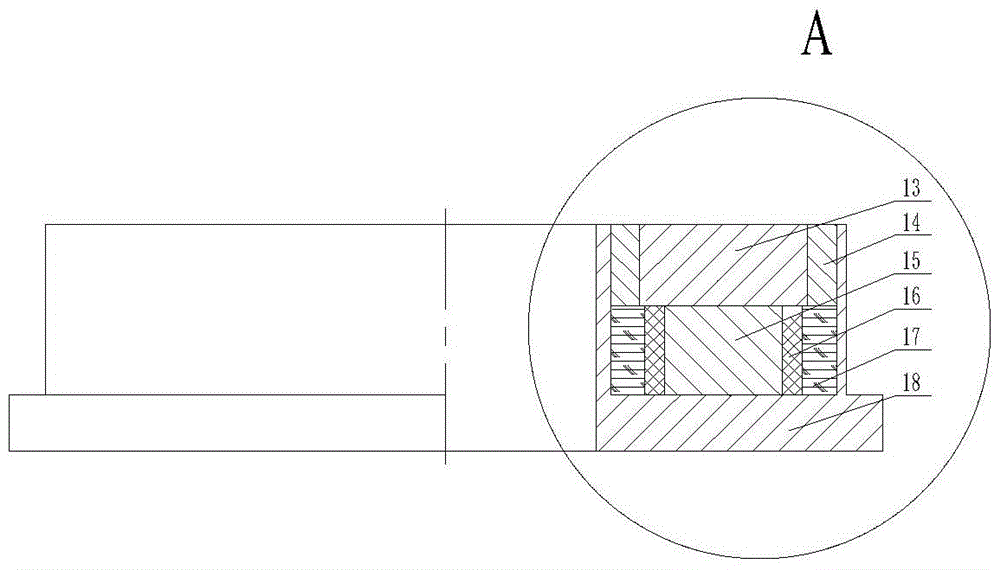

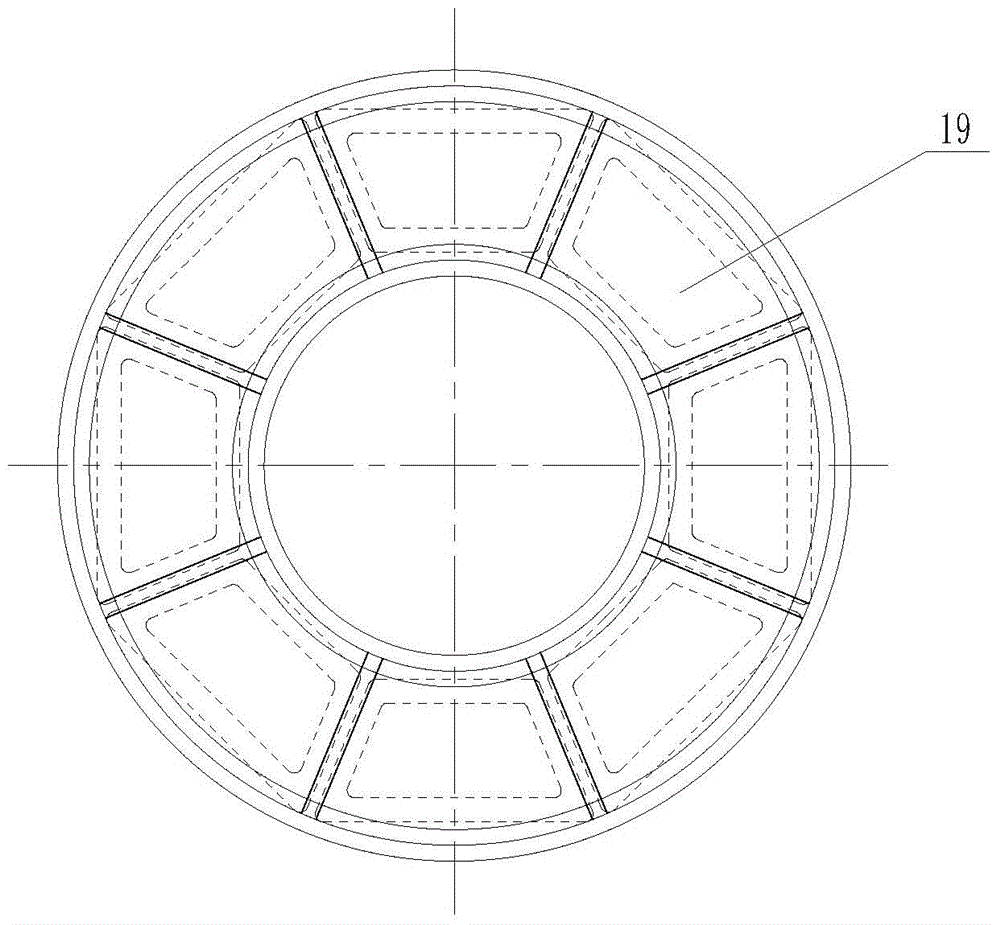

[0021] A kind of method of the present invention adopts electronically controlled permanent magnet technology to carry out blank-holding, the deep-drawing forming mold that this method uses is as figure 1 As shown, it includes an upper die base 1, a punch 2, a binder plate 3, a die 5, an electric permanent magnet chuck 6, a lower die base 7, a discharge screw 8, a set screw 9 and a press slide 10 ; The drawing and forming die assembly using electronically controlled permanent magnet technology for blank blanking adopts a formal structure, the punch 2 is on the top, the die 5 is on the bottom, and the punch 2 is installed and fixed on the upper die base 1 through the set screw 9 The press slider 10 is two left and right symmetrically installed on the upper mold base 1, the upper mold base 1 and the press slider 10 are in interference fit, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com