Cement mixer

A technology for cement mixers and mixing pots, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of inability to move, high risk, troublesome feeding, etc., and achieve low cost, high safety, The effect of increasing the space for feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

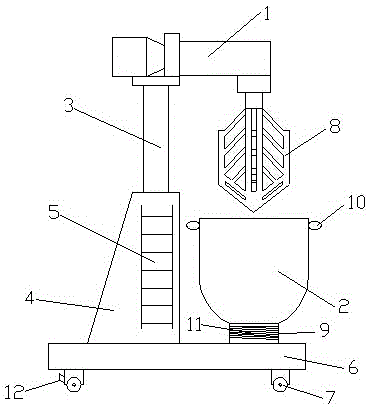

[0018] Such as figure 1 The shown cement mixer includes a mixer main body 1 and a mixing pot 2, the mixer main body 1 is installed on a column 4 through a lifting column 3, and a ladder 5 is arranged on the outer wall of the column 4, and the column 4 Installed on the base 6, the bottom of the base 6 is provided with castors 7, the mixer main body 1 is provided with a stirring blade 8, and the stirring pot 2 is provided directly below the stirring blade 8, and the stirring pot 2 A pot base 9 is provided directly below the pot base 9, and the pot base 9 is fixedly installed on the base 6. Both ends of the stirring pot 2 are provided with hanging rings 10, and a spring 11 is arranged in the pot base. The casters There is a brake fixing device 12 on it.

[0019] Working principle of the present invention is:

[0020] Before use, first transport the cement mixer to the designated location, then use the brake fixing device 12 to fix it, and then raise the main body of the mixer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com