Operation method of cable repair device

An operation method and cable technology, which is applied in the field of cable repair devices, can solve the problems of impurity and water vapor entering, easy cracks, explosions, etc., and achieve the effects of quality assurance, economic burden reduction, and price unaffected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

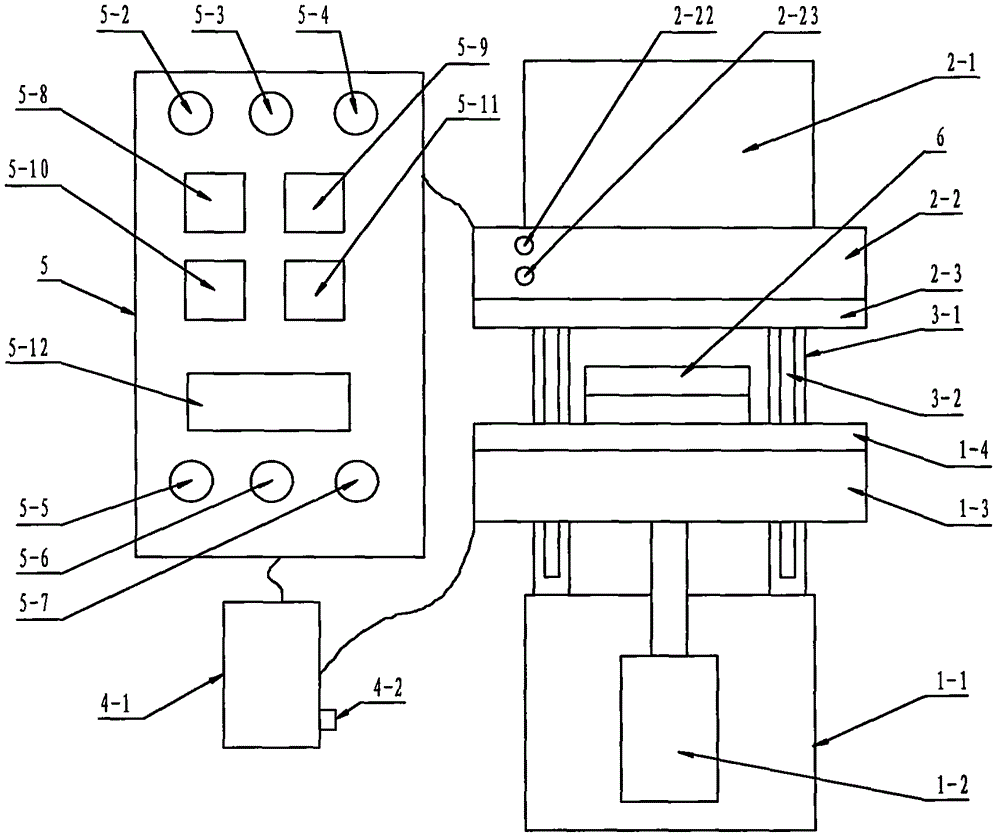

[0017] A pair of side columns 3-1 are set between the top of the base 1-1 and the upper motor case 2-1, a pair of guide rails 3-2 are set on the pair of side columns 3-1, and a lower pressing block 1-1 is set above the base 1-1. 3. Set the lower heating plate 1-4 above the lower pressing block 1-3, set the repair mold 6 above the lower heating plate 1-4, set the cylinder 1-2 in the base 1-1, and the upper end of the piston rod of the cylinder 1-2 and the lower The center of the lower surface of the pressing block 1-3 is set correspondingly, and a pair of sliders are arranged corresponding to a pair of guide rails 3-2 behind the lower pressing block 1-3, so that the lower pressing block 1-3 slides up and down along the pair of guide rails 3-2, and the upper motor An upper pressing block 2-2 is arranged under the chassis 2-1, an upper heating plate 2-3 is arranged under the upper pressing block 2-2, and a start indicator light 2-22 and a stop indicator light 2-23 are arranged on ...

Embodiment 2

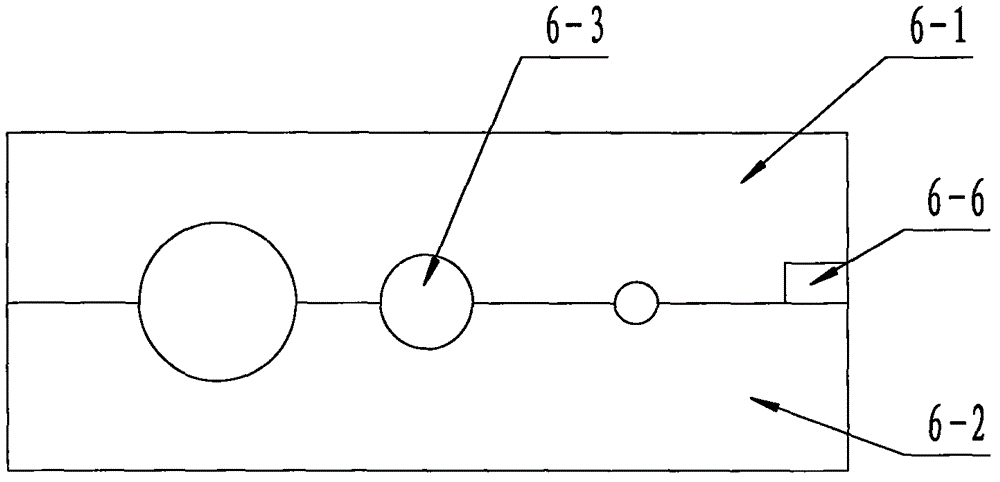

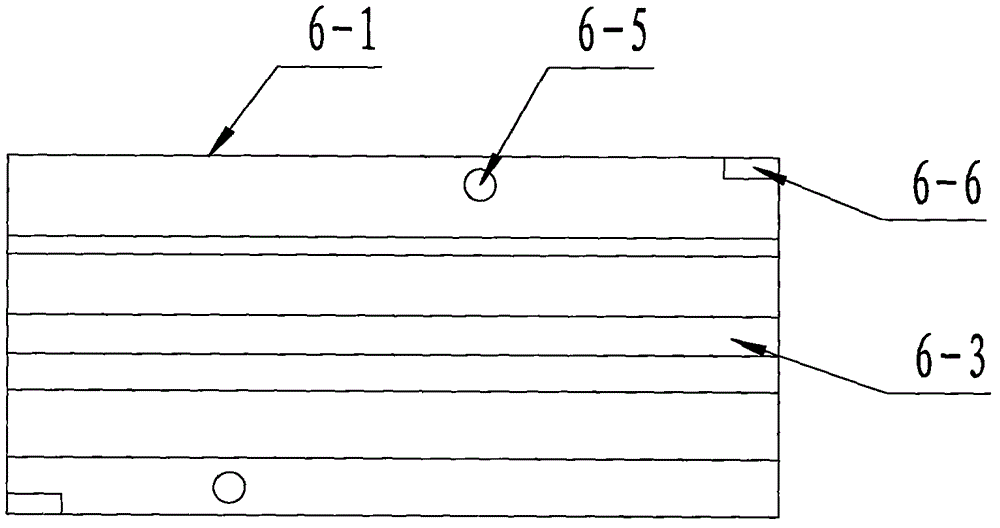

[0020]The upper die 6-1 and the lower die 6-2 are separately placed on the lower heating plate 1-4, and the cable groove 6-3 with the same specification as the cable to be repaired is selected, and the semicircular wire groove 6 of the lower die 6-2 is Spread high-temperature polyester film on the inside of -3, put the cracked section of the cable to be repaired on the high-temperature polyester film in the wire slot 6-3, spread the high-temperature polyester film on the top of the cable crack, and press mold 6-1 The semi-circular trunking 6-3 of the same specification is pressed on the high-temperature polyester film, and the plug 6-5 of the upper die 6-1 is inserted into the slot 6-4 of the lower die 6-2 to make the upper die 6-1 and the lower die 6-2 are merged, and the merged circular trunking 6-3 is pressed against the cable cracking section, and the motor operation button 5-2 on the control box 5 is pressed, and the power indicator 5-7 is on , set the heating time in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com