Method and system for controlling torque of four-wheel-drive vehicle

A technology for torque control and vehicles, applied in the field of torque control methods and systems for four-wheel-drive vehicles, capable of solving problems affecting vehicle dynamics, and achieving the effects of meeting power requirements, excellent fuel economy, and the most fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

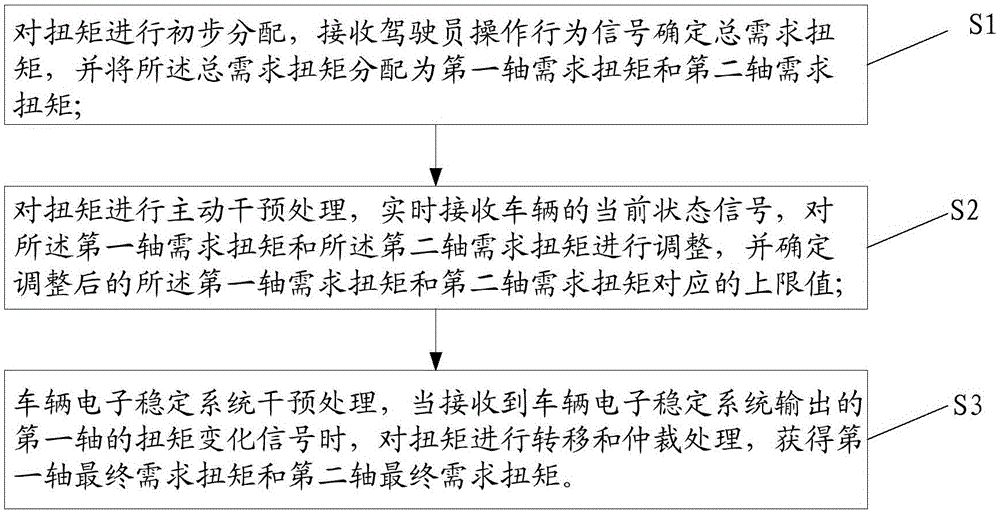

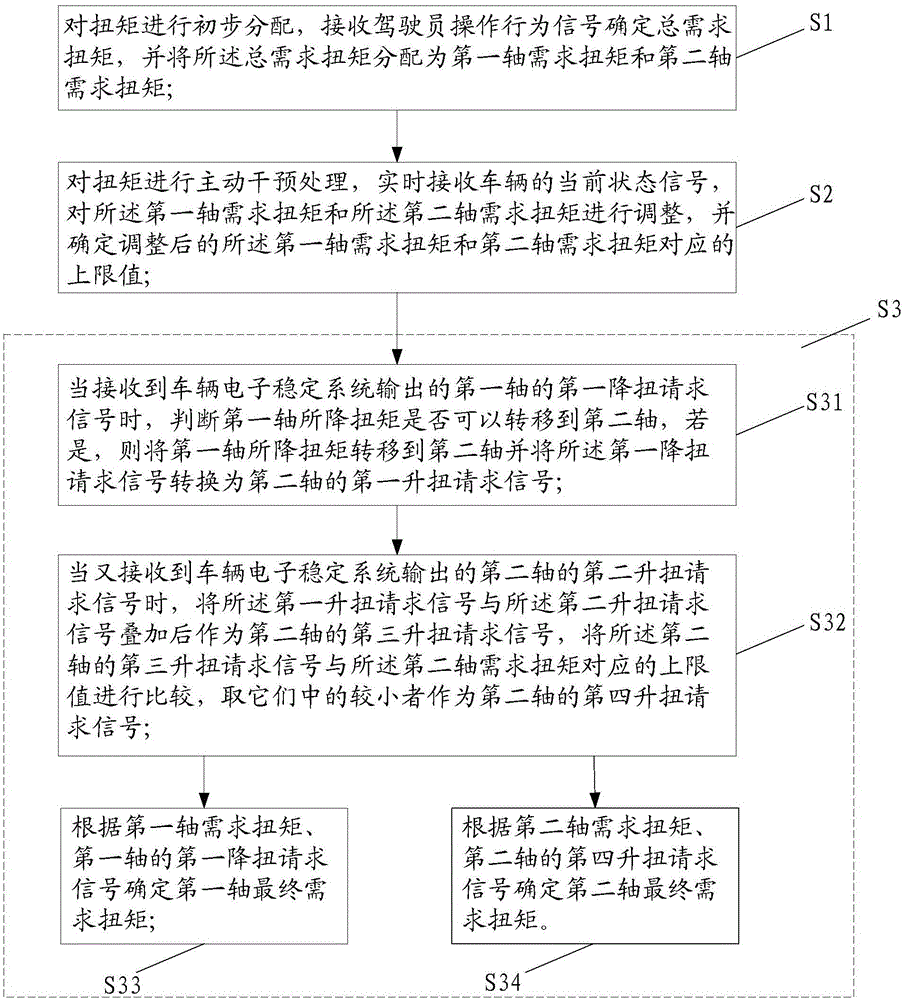

[0047] like figure 1 As shown, the present embodiment provides a torque control method for a four-wheel drive vehicle, which may include the following steps:

[0048] S1: Preliminarily distribute the torque, receive the driver's operation behavior signal to determine the total demand torque, and distribute the total demand torque into the first axle demand torque and the second axle demand torque. The driver's operation behavior signal includes: one or more of an accelerator pedal opening signal, a brake pedal opening signal, a gear lever position signal, a mode signal, and a vehicle speed signal. According to the received driver's operation behavior signal, the driver's demand intention for the torque at the wheel can be analyzed to obtain the total demand torque, and then the total demand torque is allocated with the goal of optimizing fuel economy to obtain the first axle demand torque and second shaft demand torque. Wherein, the first shaft is a front shaft and the secon...

Embodiment 2

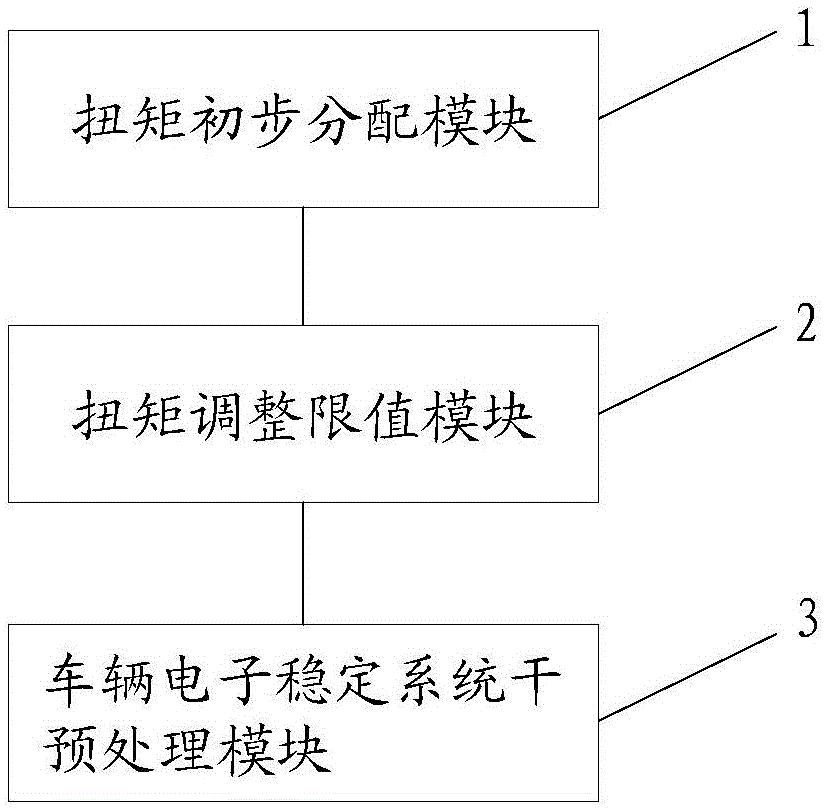

[0066] like image 3 As shown, the present embodiment provides a four-wheel drive vehicle torque control system, including:

[0067] The torque preliminary distribution module 1 is used for preliminary distribution of torque, receiving the driver's operation behavior signal to determine the total demand torque, and distributing the total demand torque into the first axle demand torque and the second axle demand torque. The driver's operation behavior signal includes: one or more of an accelerator pedal opening signal, a brake pedal opening signal, a gear lever position signal, a mode signal, and a vehicle speed signal. Wherein, the first shaft is a front shaft and the second shaft is a rear shaft; or the first shaft is a rear shaft and the second shaft is a front shaft.

[0068] The torque adjustment limit module 2 is used to actively intervene in the torque, receive the current state signal of the vehicle in real time, adjust the first shaft demand torque and the second shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com