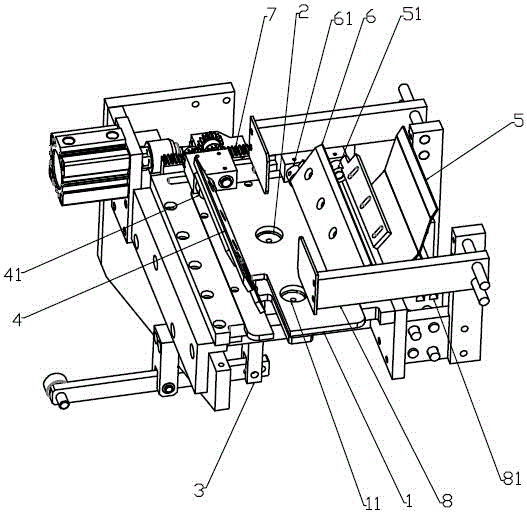

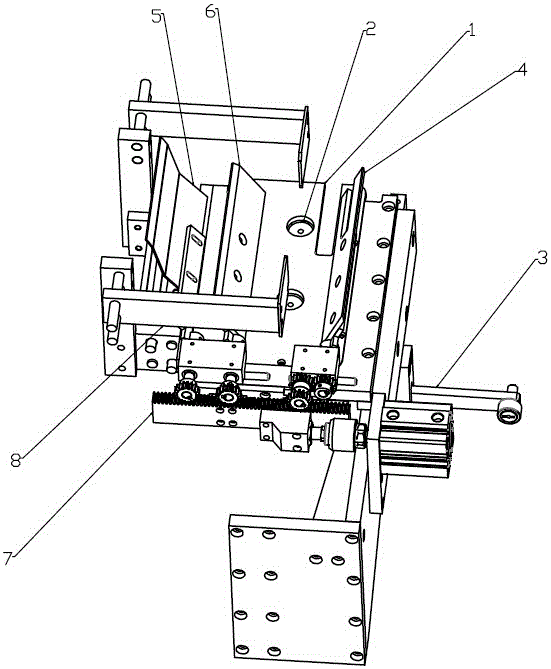

A bag-removing and folding mechanism of a flat-bottomed bag forming machine

A folding mechanism and molding machine technology, applied in the field of machinery, can solve the problems of easily damaged flat bottom bags, hidden safety hazards, etc., and achieve the effects of high production efficiency, reduced pollution links, and good molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

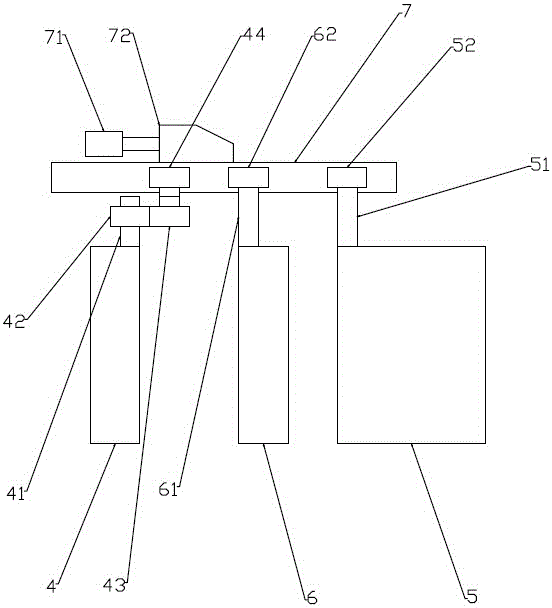

Embodiment 1

[0029]Embodiment 1 The complete working process of the present invention is as follows: when the bag-removing and folding mechanism is on standby, the corner seat 32 props up one end of the lever 31, the other end of the lever 31 sinks, the spring 34 is compressed, and the suction device 2 is lower than the upper surface of the platform 1 ; When the mold with flat bottom bag came to the top of the bag-removing folding mechanism through the transfer devices such as the turntable and the conveyor belt, the bag-removing folding mechanism rose, the lever 31 broke away from the corner seat 32, the compressed spring 34 stretched, and the support 33 was pushed upwards. Make the suction device 2 pass through the through hole 11 and rise to the bottom of the flat-bottomed bag to suck it tightly; then the mold releases the flat-bottomed bag, the bag-off folding mechanism descends, and one end of the lever 31 is blocked by the corner seat 32 and propped up, so that the other end of the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com