Automobile seat sliding rail packaging box

A car seat slide rail and packaging box technology, which is applied in the direction of packaging, transportation and packaging, and containers to prevent mechanical damage, etc., can solve the problem of high transportation costs and recycling costs, high quality of plastic box pallets, waste of space in packaging containers, etc. problems, to achieve the effect of high utilization of packaging space, easy warehouse management, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

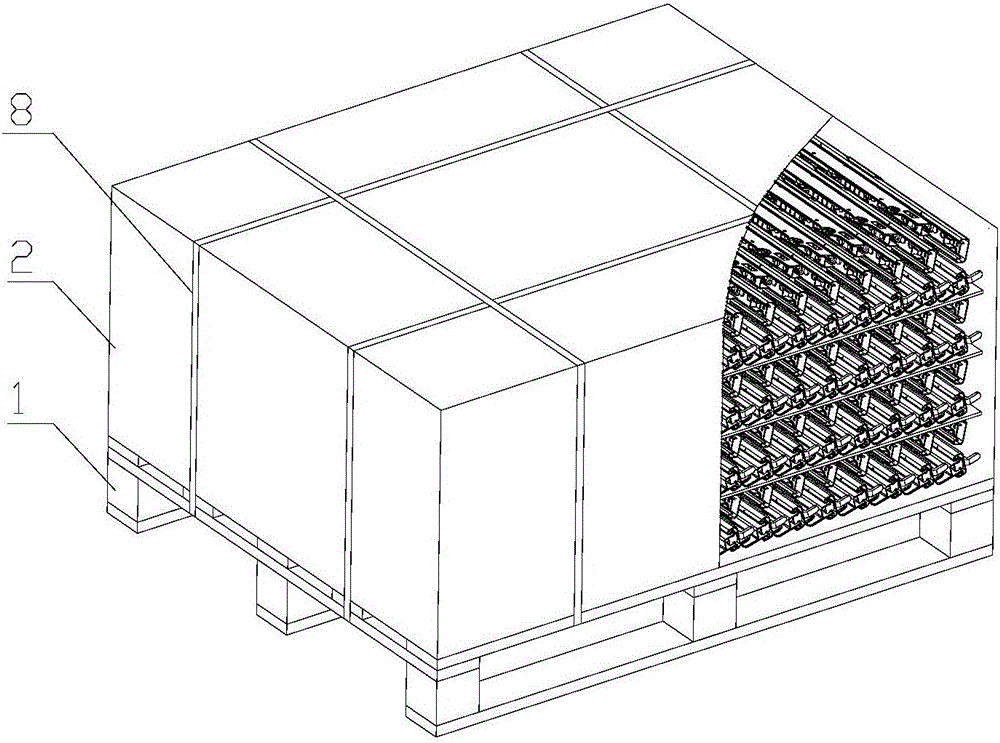

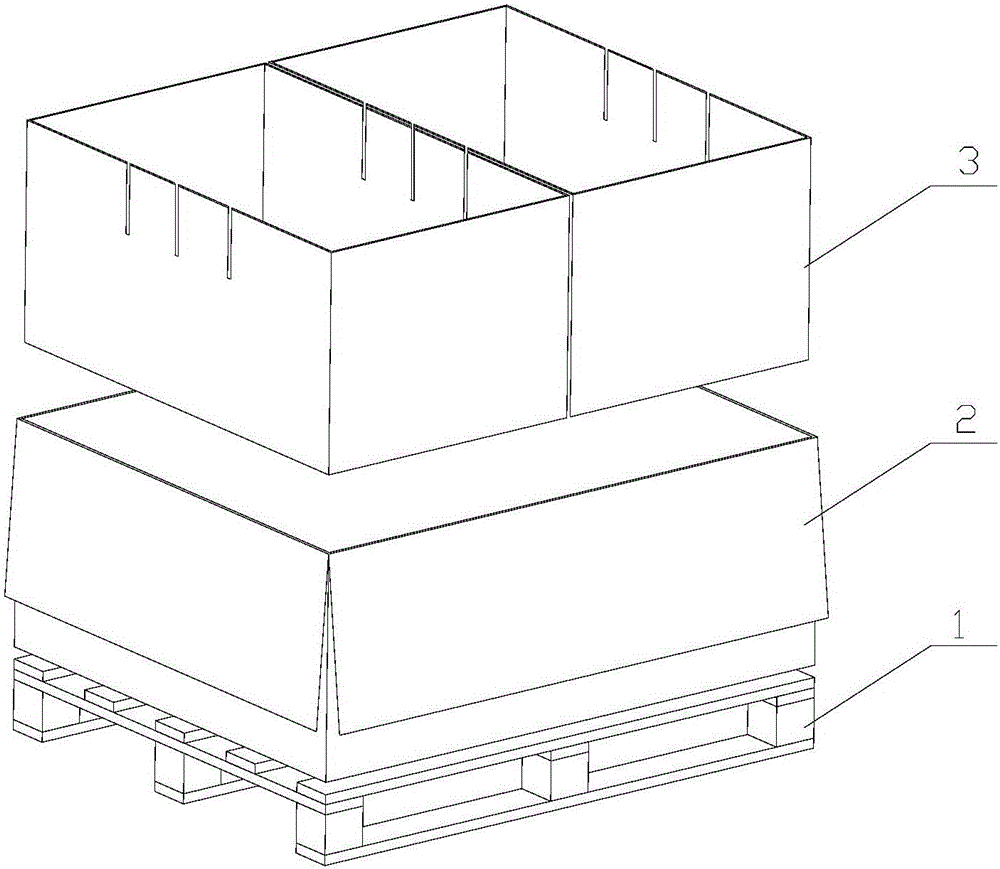

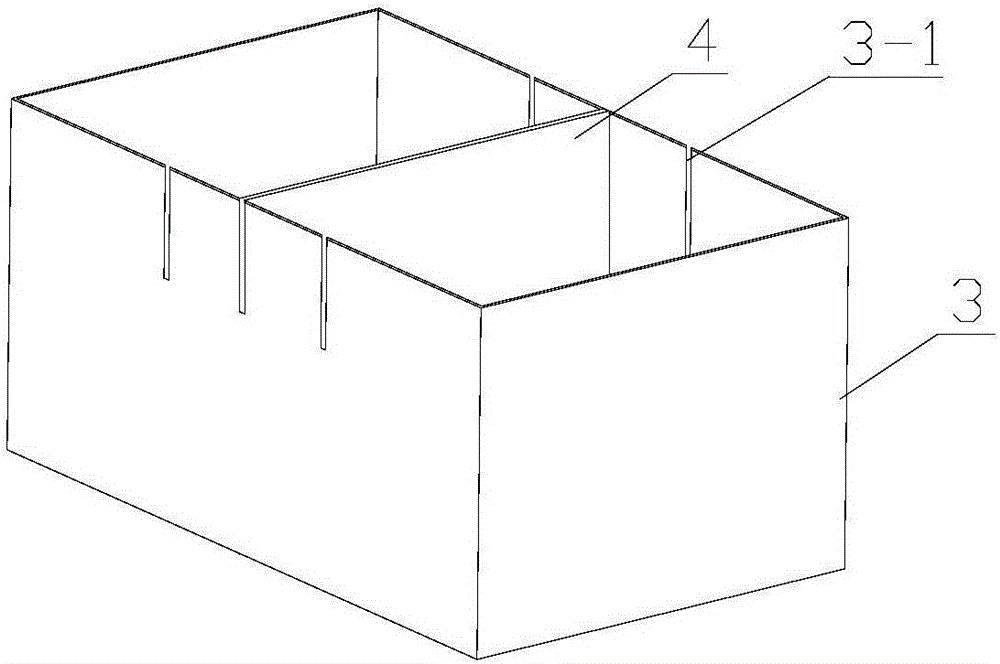

[0034] As shown in the figure, in a specific embodiment, the car seat slide rail packing box provided by the present invention adopts the packing unit that three corrugated cartons 2 and wooden pallet 1 are combined to carry out transportation (see figure 1 ), the outer packaging carton 2 uses three corrugated cartons, and two rectangular corrugated cardboard reinforcement frames 3 are arranged inside to increase the overall strength of the carton 2 (see figure 2 ), the upper part of the reinforcement frame 3 is provided with a slot 3-1, and according to the product size, select the corresponding slot 3-1 to insert the corrugated paper partition 4 to realize fast partitioning (see image 3 ), the two ends of the inner slide rail 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com