Chemical comprehensive treatment method of fatlute containing polymers

A technology for polymerizing oily sludge and oily sludge, applied in chemical instruments and methods, sludge treatment, oxidized water/sewage treatment, etc., can solve the problems of long treatment time, large volume, heavy equipment, etc., and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

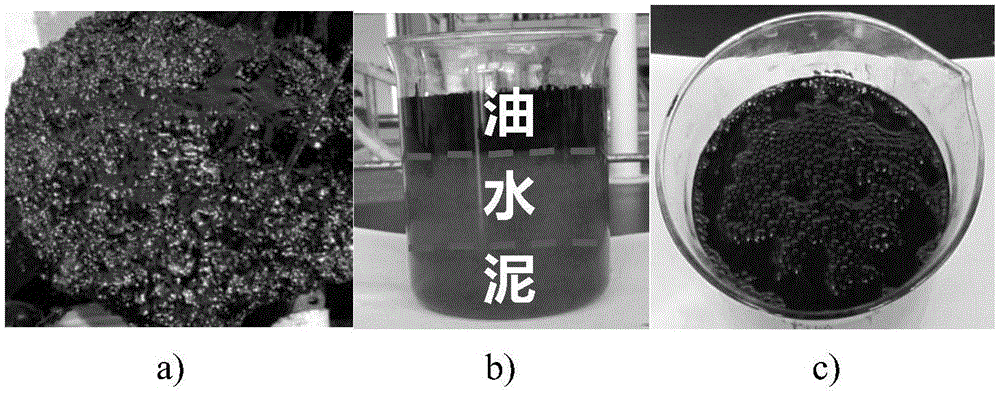

[0049] Example 1. Method for separating crude oil from polymer-containing sludge

[0050] 1. Weigh 150ml of water, 0.2g of petroleum sodium sulfonate (the average molecular weight of the distillate used in petroleum sodium sulfonate is 280-400), 0.1g of sodium pyrophosphate and 0.2g of EDTA-2Na, add 200g of poly-sludge sample in a beaker (such as figure 1 a) shown in), and then put the beaker containing the poly-sludge in a constant temperature water bath to raise the temperature to 80°C and stir. At the same time, weigh 3g sodium ferrate, 2.5g ammonium persulfate-triethanolamine (dosing ammonium perpersulfate and triethanolamine according to the mass ratio of 20-40:1), add them to 80ml water, stir well, and then put them within 10min Add it to the above flask, stir and react for 7h at 80°C.

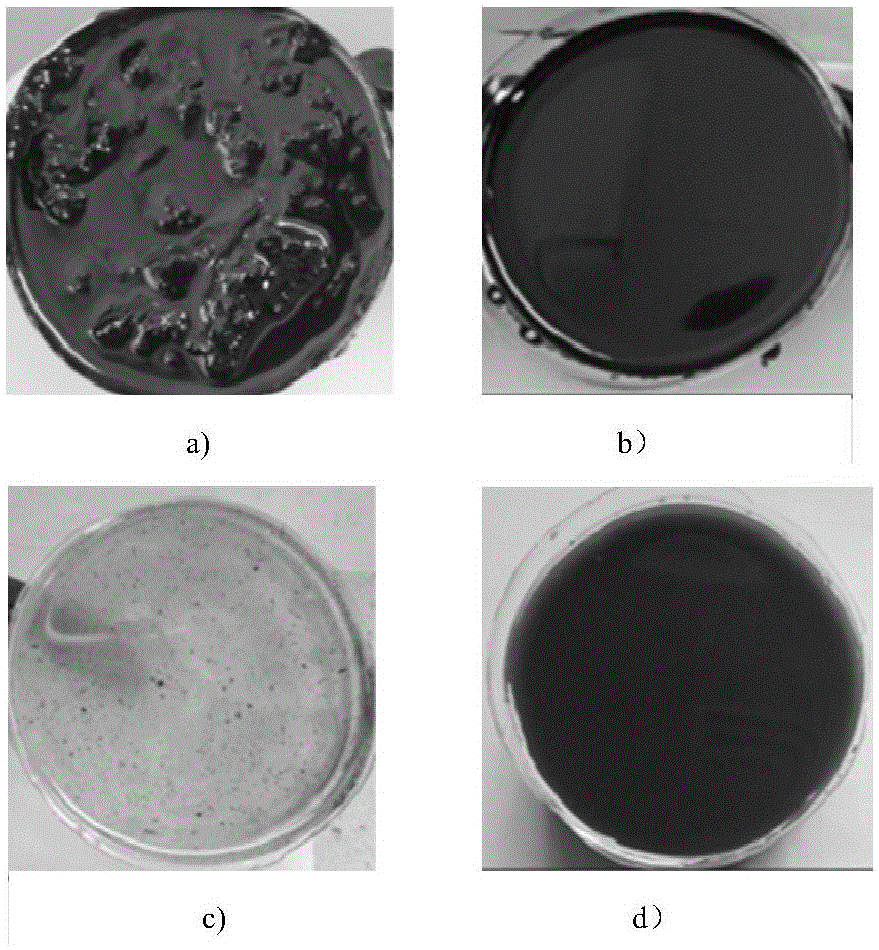

[0051] 2. Take out the sample system processed in step 1, pour it into a sedimentation beaker, add 0.03g of organosiloxane modified polyoxyethylene-polyoxypropylene ether demulsifier (through...

Example Embodiment

[0054] Example 2. Method for separating crude oil from polymer-containing sludge

[0055] 1. Weigh 200g sample containing polysludge and 0.16g sodium nonyldodecylbenzene sulfonate into a three-necked flask, add 150ml of water, and place it in a constant temperature water bath to raise the temperature to 60°C. At the same time, weigh 3g class Fenton reagent (H 2 O 2 (30% aqueous solution) and manganese acetate in a mass ratio of 40:1), 1g sodium persulfate-ferrous acetate redox reagent system (ammonium persulfate-triethanolamine (ammonium perpersulfate and triethanolamine according to the mass ratio of 20 ~40:1, respectively add) 0.15g sodium tartrate in 80ml water, stir evenly, then add the above mixture to the flask containing poly-sludge within 30min, and stir and react at 60℃ for 5h.

[0056] 2. Take out the above-mentioned sample that has been reacted for 5 hours at 60°C in step 1), pour it into a sedimentation beaker, add 0.025g organosiloxane modified polyoxyethylene-polyoxyp...

Example Embodiment

[0059] Example 3 Method for separating crude oil from polymer-containing sludge

[0060] 1. Weigh 200g of poly-sludge sample into a three-necked flask, add 150ml of water, and place it in a constant temperature water bath to raise the temperature to 40°C. Weigh 2g of sodium perborate, 1g of calcium peroxide, 0.2g of sodium pyrophosphate, 0.3g of sodium petroleum sulfonate, 0.1g of xylene in 50g of water, stir well, and then add the above mixture to the flask containing polysludge within 10 minutes In the medium, soaking for 2h, and then heating to 55°C for 7h.

[0061] 2. Take out the above-mentioned sample reacted at 55℃ for 7h in step 1, pour it into a sedimentation beaker, add 0.03g organosiloxane modified polyoxyethylene-polyoxypropylene ether demulsifier (through methyl hydrogen silicone oil (polymerization) It is prepared by hydrosilylation reaction with allyl-terminated polyoxyethylene-polyoxypropylene block polyether, which contains 0.8% Si-H bond. The block moles of polyo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap