Preparation method of 1,3-propane sultone derivative

A technology of propane sultone and propene sultone, which is applied in the field of preparation of 1,3-propane sultone derivatives, can solve the problems of long steps, low yield, large pollution, etc., and achieve reaction Effect of long time, high reaction temperature and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

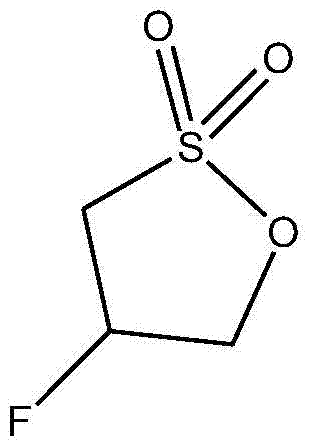

Embodiment 1

[0024] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propene sultone into 200ml of dichloromethane, and then pass in HF gas, control the reaction pressure to 1atm, the reaction temperature to 10°C and the reaction time to 1h , to obtain 2-fluoro-1,3-propane sultone, the calculated yield is 46.0%, the purity is 99.4%, and the product moisture is 16PPM.

Embodiment 2

[0026] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propene sultone into 400ml of dichloromethane, and then pass in HF gas, control the reaction pressure to 7atm, the reaction temperature to 35°C and the reaction time to 5h , to obtain 2-fluoro-1,3-propane sultone, the calculated yield is 74.4%, the purity is 99.6%, and the product moisture is 17PPM.

Embodiment 3

[0028] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propene sultone into 800ml of dichloromethane, and then pass in HF gas, control the reaction pressure to 10atm, the reaction temperature to 50°C and the reaction time to 10h , to obtain 2-fluoro-1,3-propane sultone, the calculated yield is 87.2%, the purity is 99.8%, and the product moisture is 18PPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com