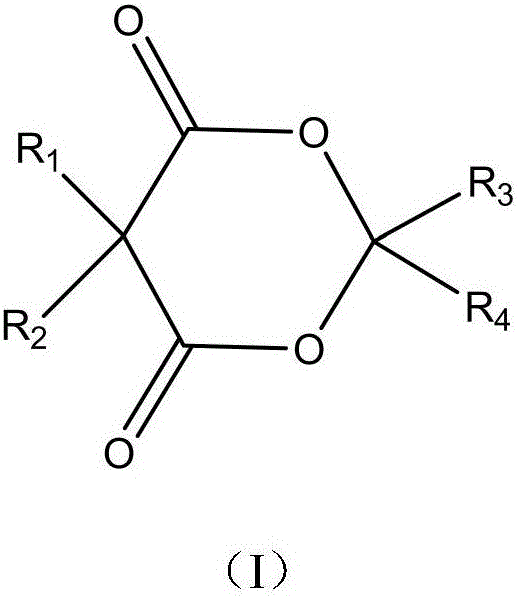

Catalyst component for olefin polymerization and preparation method thereof

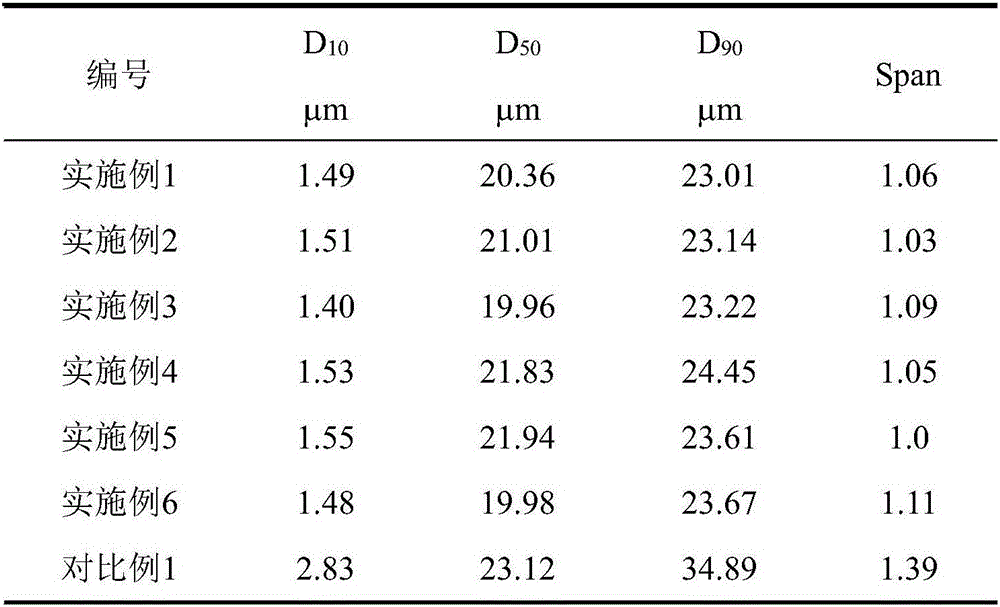

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization, can solve the problems of long synthetic route, high production cost, and difficult synthesis, and achieve the effects of narrow particle size distribution, high isotacticity of polymers, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Synthesis of solid titanium main catalyst components:

[0057] ⑴ After high-purity N 2 In a fully replaced glass bottle, 7.14 g (75 mmol) of anhydrous magnesium chloride, 37.5 ml of decane and 35.1 ml (225 mmol) of 2-ethylhexanol were added successively, and the suspension was heated at 130°C for 3 hours to obtain homogeneous solution.

[0058] (2) Add the magnesium chloride alcoholate solution in step (1) dropwise to 200 ml (1.8 moles) of titanium tetrachloride solution maintained at -24°C.

[0059] (3) Heat the mixture in step (2) to 40°C within a certain period of time, add 1.08 g (7.5 mmol) of cycloisopropyl malonate to the mixture, and then raise the temperature to 110°C. After the temperature reached 110°C, the mixture was stirred at the same temperature for 2 hours.

[0060] ⑷Recover the generated solid by hot filtration. It was resuspended in 200 ml of titanium tetrachloride, then reheated to 110°C, stirred for 2 hours, and filtered. The solid was thorou...

Embodiment 2

[0064] 1. Synthesis of solid titanium main catalyst components:

[0065] Except replacing cycloisopropyl malonate with cycloisopentyl malonate, other is the same as embodiment 1.

[0066] The analysis results of solid titanium main catalyst components are as follows: Ti, 2.83%; Mg, 16.8%; electron donor, 9.2%.

[0067] 2. Polymerization: with embodiment 1, catalyst analysis results are shown in Table 1, and polymerization results are shown in Table 2 and Table 3.

Embodiment 3

[0069] 1. Synthesis of solid titanium main catalyst components:

[0070] Except that cycloisopropyl malonate is replaced with cycloisopropyl malonate, other is the same as embodiment 1.

[0071] The analysis results of solid titanium main catalyst components are as follows: Ti, 2.4%; Mg, 15.9%; electron donor, 11.3%.

[0072] 2. Polymerization: with embodiment 1, catalyst analysis results are shown in Table 1, and polymerization results are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com