A kind of water-based paint and preparation method thereof

A water-based paint and formulation technology, applied in the direction of coating, can solve problems such as poor construction performance, and achieve the effects of good suspension, reduced energy consumption, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

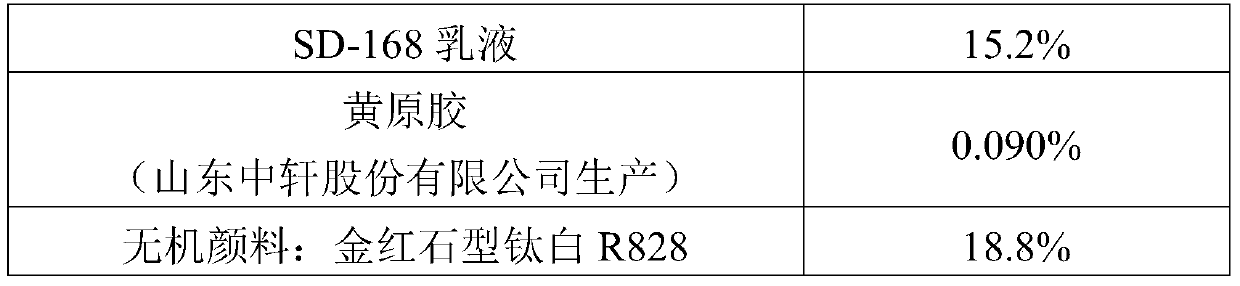

[0071] The raw material formulation (wt %) of the aqueous paint of embodiment 1 is as follows table 1.

[0072] Table 1

[0073]

[0074]

[0075] The preparation method of this aqueous paint comprises the steps:

[0076] (1) Stir xanthan gum solution and 48.0wt% deionized water at a rotating speed of 1200rpm, mix and dissolve to obtain solution A; The defoamer and solution A were stirred at a speed of 800rpm, and mixed uniformly to obtain solution B; solution B, inorganic pigments, fillers and 35.0wt% deionized water were stirred at a speed of 1500rpm at room temperature, mixed evenly, and dispersed to The particle size of the inorganic pigment and inorganic filler is below 45 μm to obtain slurry C;

[0077] (2) At a stirring speed of 600rpm, add the remaining wetting and dispersing agent, remaining carbomer, remaining defoamer, bactericide, acrylic emulsion, coalescent, antifreeze and remaining deionized water, mix evenly, then;

[0078] Wherein, percentages are we...

Embodiment 2

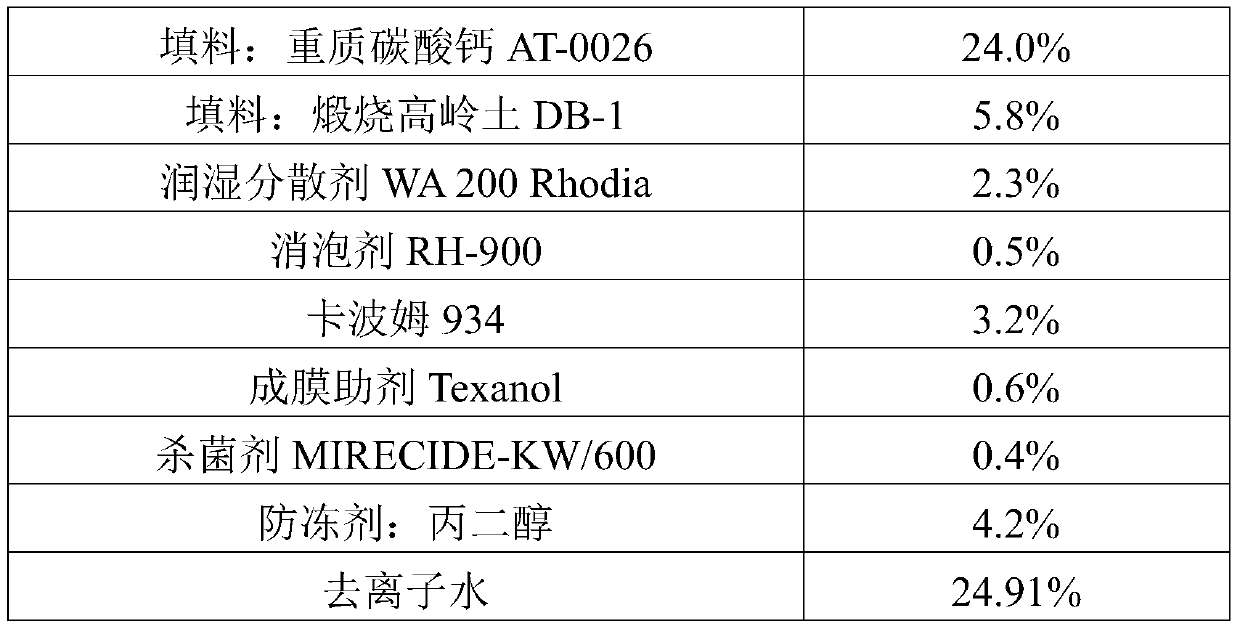

[0080] The raw material formula (wt%) of the water-based coating of embodiment 2 is as follows table 2.

[0081] Table 2

[0082]

[0083]

[0084] The preparation method of this aqueous paint comprises the steps:

[0085](1) Xanthan gum and 50.0wt% deionized water are stirred at a rotating speed of 1100rpm, mixed and dissolved to obtain solution A; Stir the defoamer and solution A at a speed of 700rpm, mix uniformly to obtain solution B; stir solution B, inorganic pigments, fillers and 28.0wt% deionized water at room temperature at a speed of 1400rpm, mix uniformly, and disperse into the inorganic The particle size of pigments and fillers is below 45 μm to obtain slurry C;

[0086] (2) At a stirring speed of 700rpm, add the remaining wetting and dispersing agent, remaining carbomer, remaining defoamer, bactericide, acrylic emulsion, coalescent, antifreeze and remaining deionized water, mix evenly, and you can;

[0087] Wherein, percentages are weight percentages rel...

Embodiment 3

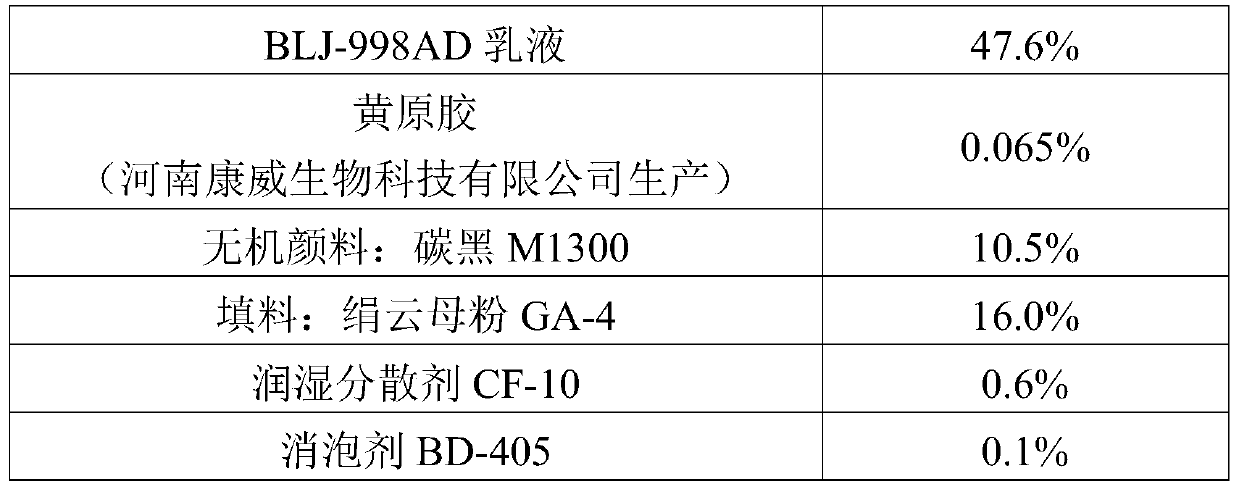

[0089] The raw material formulation (wt%) of the water-based coating of embodiment 3 is as follows table 3.

[0090] table 3

[0091]

[0092]

[0093] The preparation method of this aqueous paint comprises the steps:

[0094] (1) Stir xanthan gum and 52.0wt% deionized water at a rotating speed of 1000rpm, mix and dissolve to obtain solution A; mix 50.0wt% wetting and dispersing agent, 30.0wt% carbomer and 50.0wt% Stir the defoamer and solution A at a speed of 600rpm, mix uniformly to obtain solution B; stir solution B, inorganic pigments, fillers and 28.0wt% deionized water at room temperature at a speed of 1200rpm, mix uniformly, and disperse into the inorganic The particle size of pigments and fillers is below 45 μm to obtain slurry C;

[0095] (2) At a stirring speed of 800rpm, add the remaining wetting and dispersing agent, remaining carbomer, remaining defoamer, bactericide, acrylic emulsion, coalescent, antifreeze and remaining deionized water, mix evenly, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com