Countertop rapid mounting structure of faucet

An installation structure and faucet technology, applied in the field of machinery, can solve the problems of unguaranteed stability and small contact area with the bottom surface of the platen, and achieve the effect of increasing the contact area, convenient operation and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

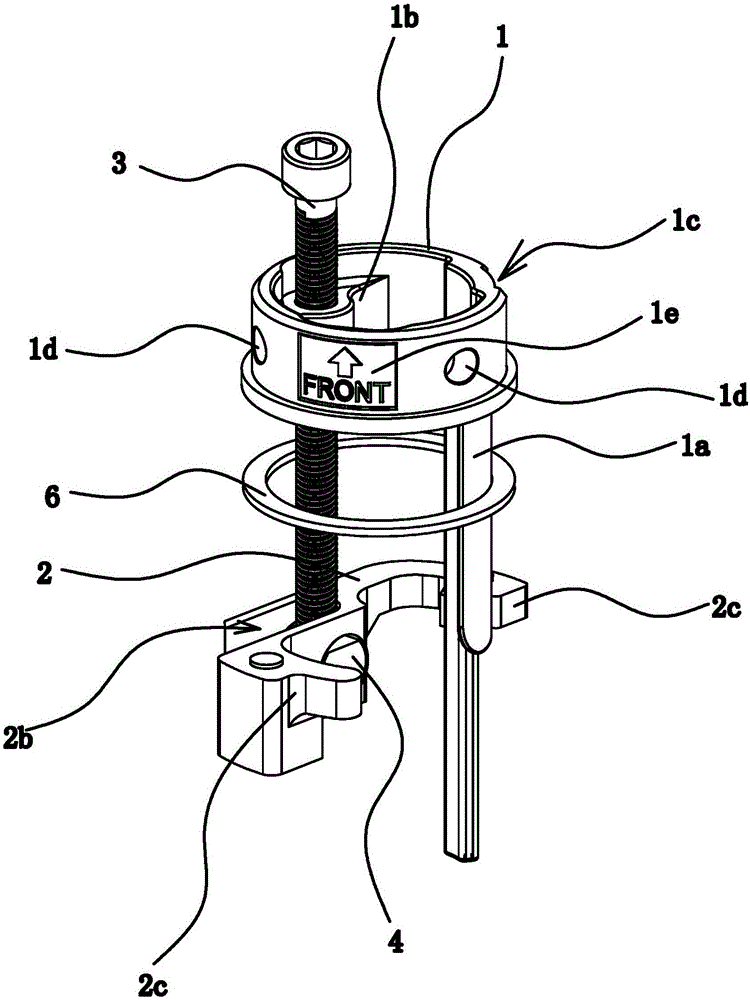

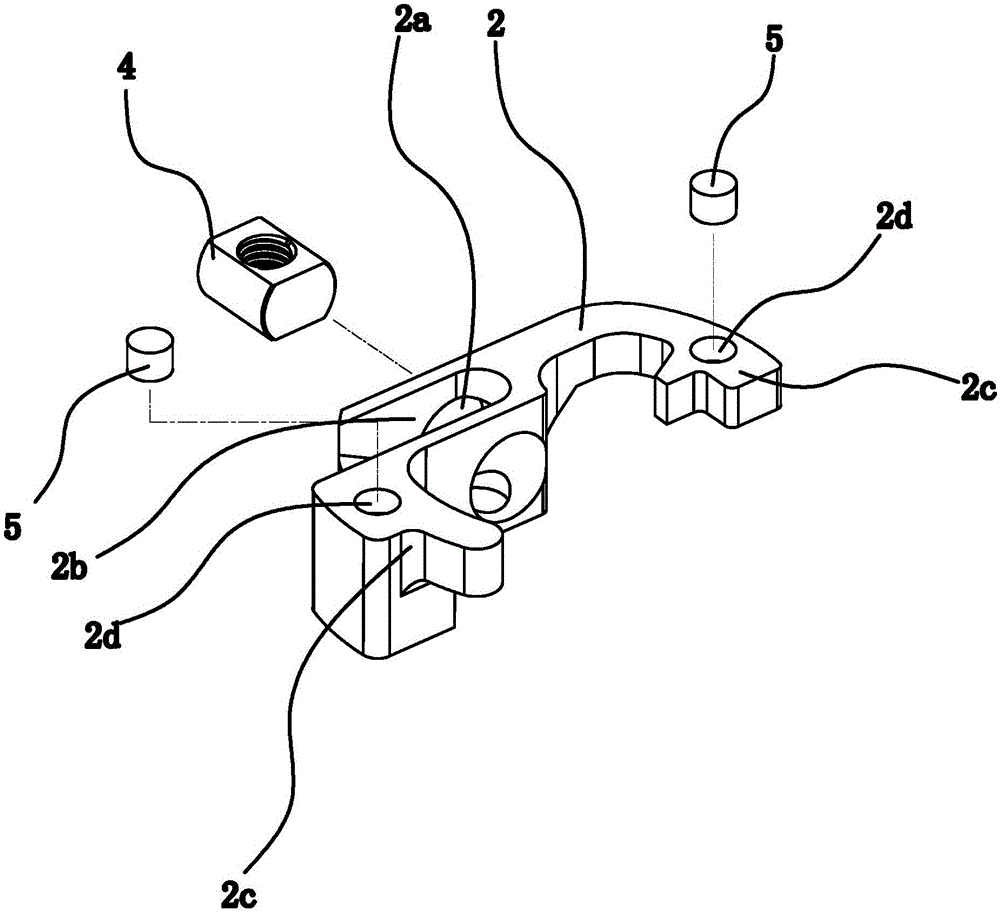

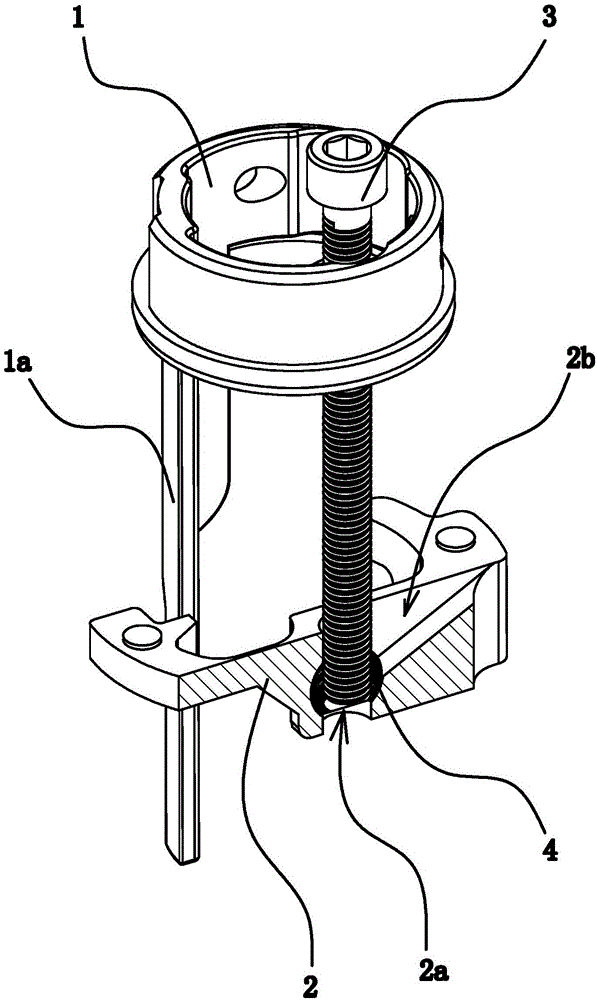

[0043] Such as figure 1 and figure 2 As shown, a quick installation structure for a faucet on a platform includes a cylindrical installation body 1 and a locking block 2 located below the installation body 1 . The outside of the installation body 1 is provided with a position mark 1e and installation adjustment holes 1d located on both sides of the position mark, and the outside of the installation body 1 is also provided with a connection fixing groove 1c from top to bottom. The inner side of the installation body 1 has a protruding connecting portion 1b, and a connecting hole is provided on the connecting portion 1b, and a locking screw 3 is arranged in the connecting hole, and the head of the locking screw 3 abuts against the upper port of the connecting hole. The middle part of the locking block 2 is provided with a positioning hole 2a that runs through the upper and lower sides of the locking block 2. The positioning hole 2a is provided with a pin shaft 4, and the pin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com