Four-gear linkage type brake clearance adjustment device

A technology of braking clearance and adjusting device, applied in the direction of slack adjuster, etc., can solve the problems of adjusting screw sticking, product function failure, affecting braking efficiency, etc., to achieve overall performance and life improvement, structure simplification, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

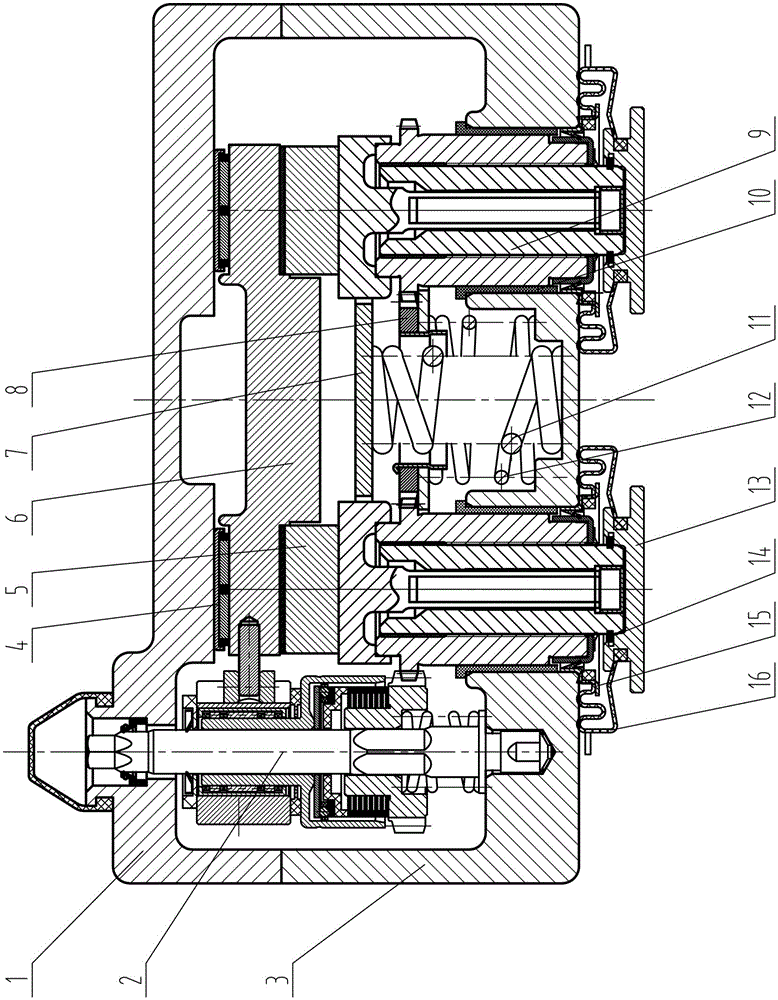

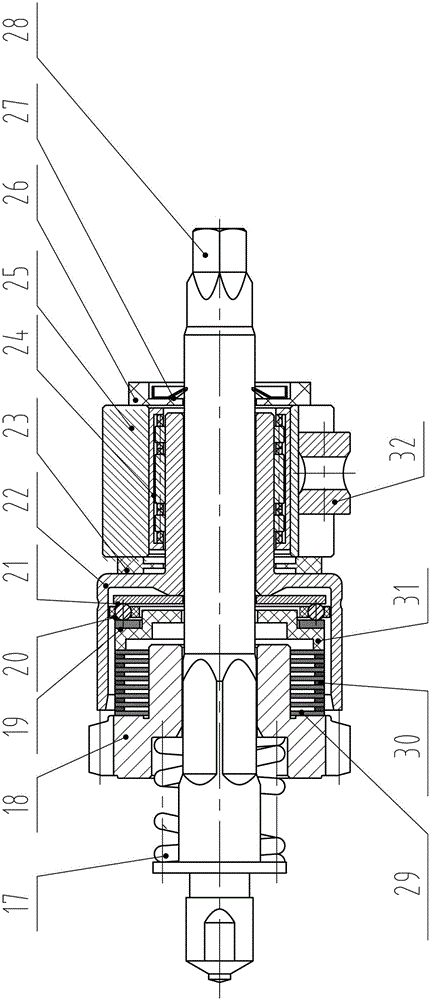

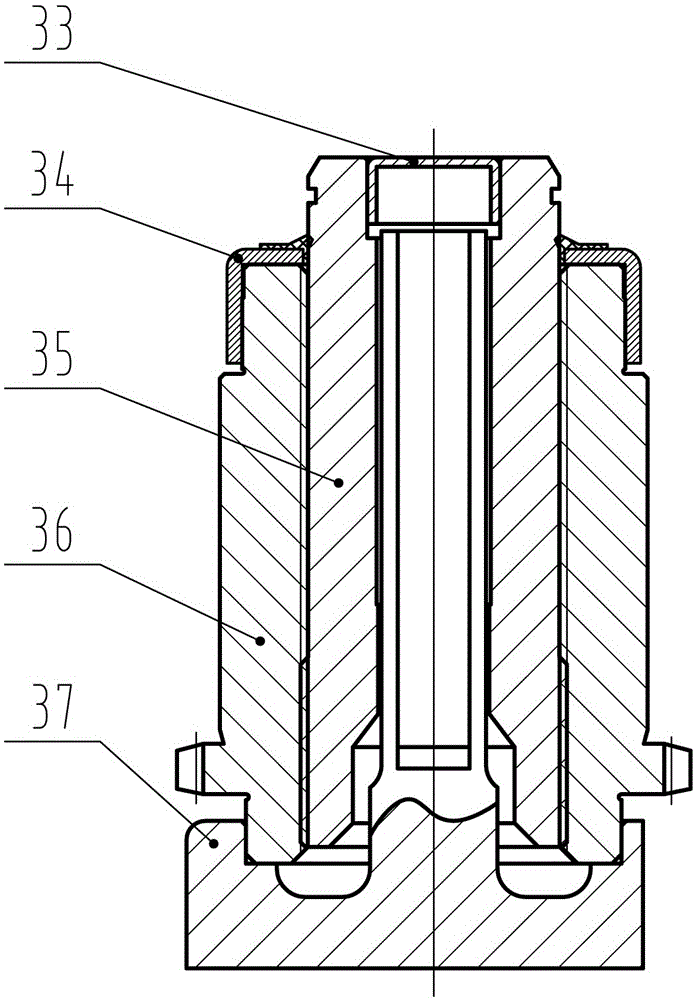

[0019] Specific implementation, such as figure 1 , figure 2 with image 3 As shown, first assemble the plastic bushing 10 and the oil seal (15) into the processing hole of the caliper body 3. After placing the return spring A11 and the return spring B12 into the processing position of the pliers body 3, install the return spring 12 Connect the gear 8 and install the two driven adjustment mechanisms 9 into the hole of the coupling gear to match the gears, clamp the driven adjustment mechanism with the clamping plate 7, and then install the manual adjuster 2 into the mounting hole in the clamp body 3. , And make the gear mesh with the gear of the driven adjustment mechanism 9, put the pressure arm 6 equipped with the roller 5 on the driven adjustment mechanism 9, and cooperate with the manual adjuster 2, and a semi-circular roller is installed inside the cover The upper cover 1 of the needle shaft 4 makes the semicircular needle roller shaft 4 match the pressure arm 6, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com