Harmonic speed reduction method and device

A harmonic deceleration and rigidity technology, applied in hoisting devices, transmission devices, gear transmission devices, etc., can solve the problems of complex movable tooth structure, failure to form products, and easy failures, etc., and achieve low manufacturing cost and simple control , The effect of improving the load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

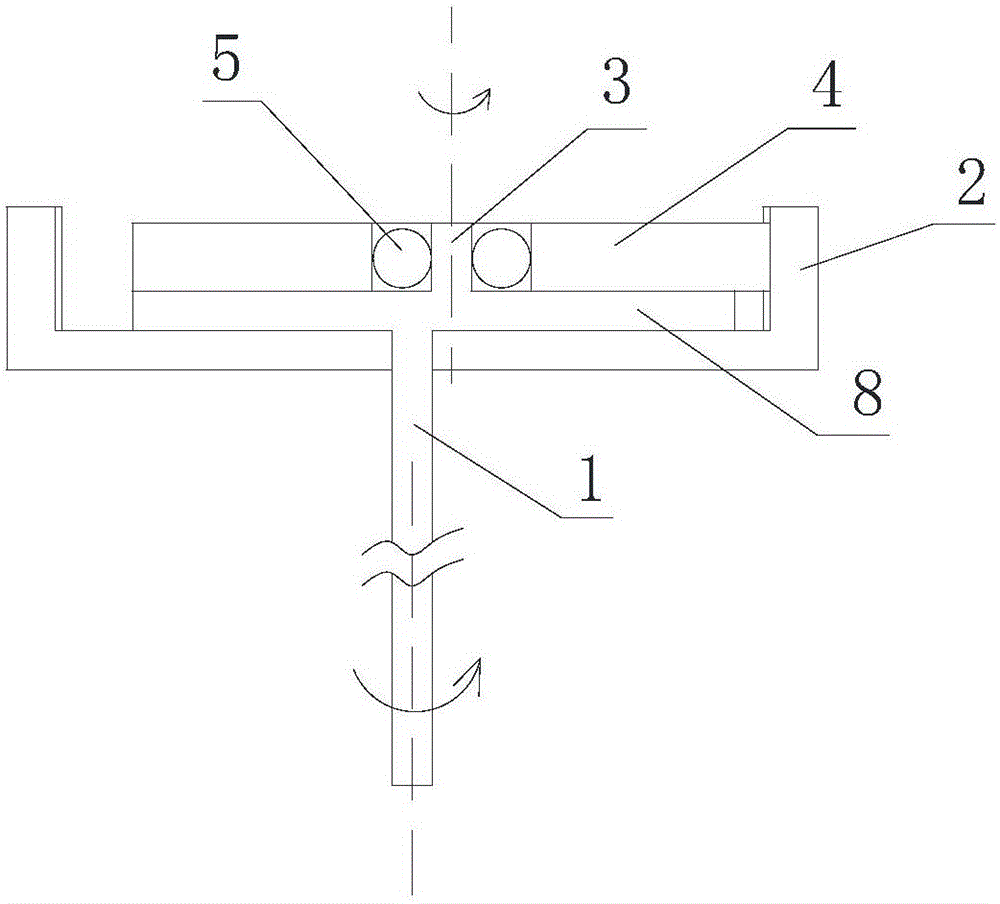

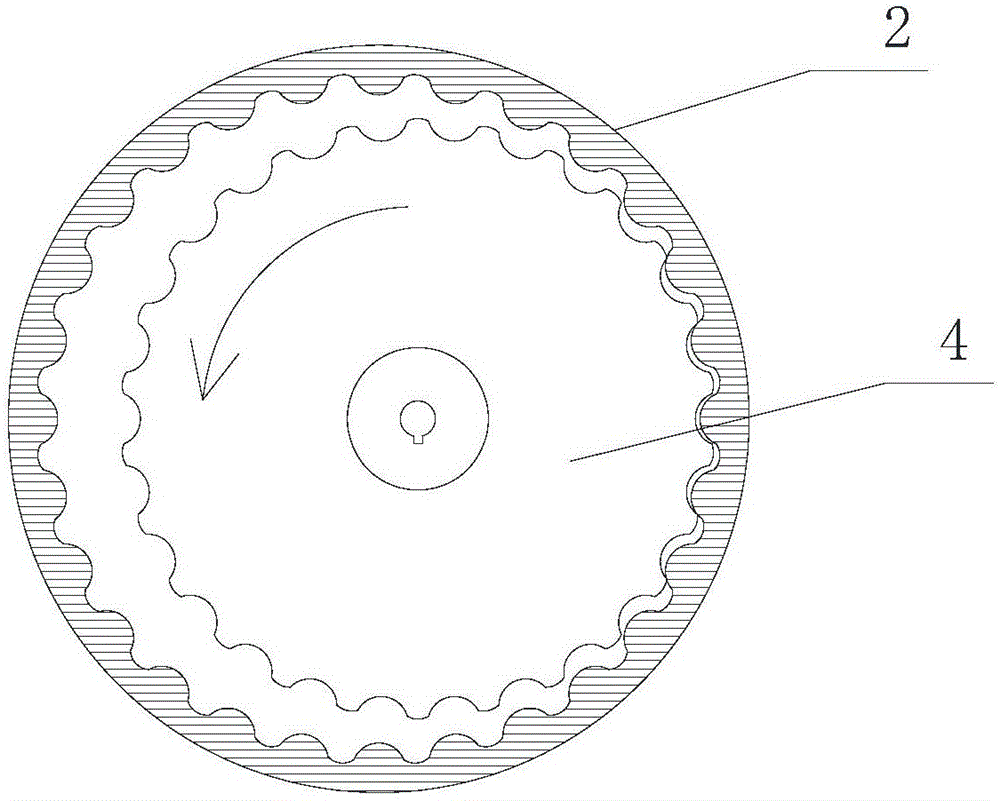

[0048] Such as Figure 5 As shown, the harmonic speed reduction device provided in this embodiment is basically the same as that in Embodiment 1, except that the rigid external gear 4 includes a first rigid external gear 41 and a second rigid external gear 42 . A first parallel eccentric shaft 31 is provided corresponding to the first rigid external gear 41 , a second eccentric shaft 32 is provided corresponding to the second rigid external gear 42 , and both the first eccentric shaft 31 and the second eccentric shaft 32 are fixed to the input shaft 1 .

[0049] Wherein, the first eccentric shaft 31 and the second eccentric shaft 32 are arranged oppositely around the input shaft 1, and the first rigid external gear 41 and the second rigid external gear 42 are folded together and meshed with different teeth of the rigid internal gear 2 respectively. .

[0050] The specific structure between the two eccentric shafts and the input shaft 1 is as follows: between the first eccentr...

Embodiment 3

[0054] Such as Figure 6 As shown, the harmonic deceleration device provided by this embodiment is basically the same as the second embodiment, the difference is that the first eccentric shaft 31 and the second eccentric shaft 32 are not fixed, but the second parallel eccentric The shaft 32 is fixed on the first rigid external gear 41 . The advantage of this arrangement is that the gap between adjacent rigid external gears is minimized, the structure is compact, and the assembly is simpler and more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com