A kind of catalytic pickling solution and pickling method for 400 series stainless steel annealing wire

A stainless steel and catalytic acid technology, applied in the field of steel surface treatment, can solve the problems of high energy consumption, stainless steel companies have no independent intellectual property rights, and high processing temperature, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

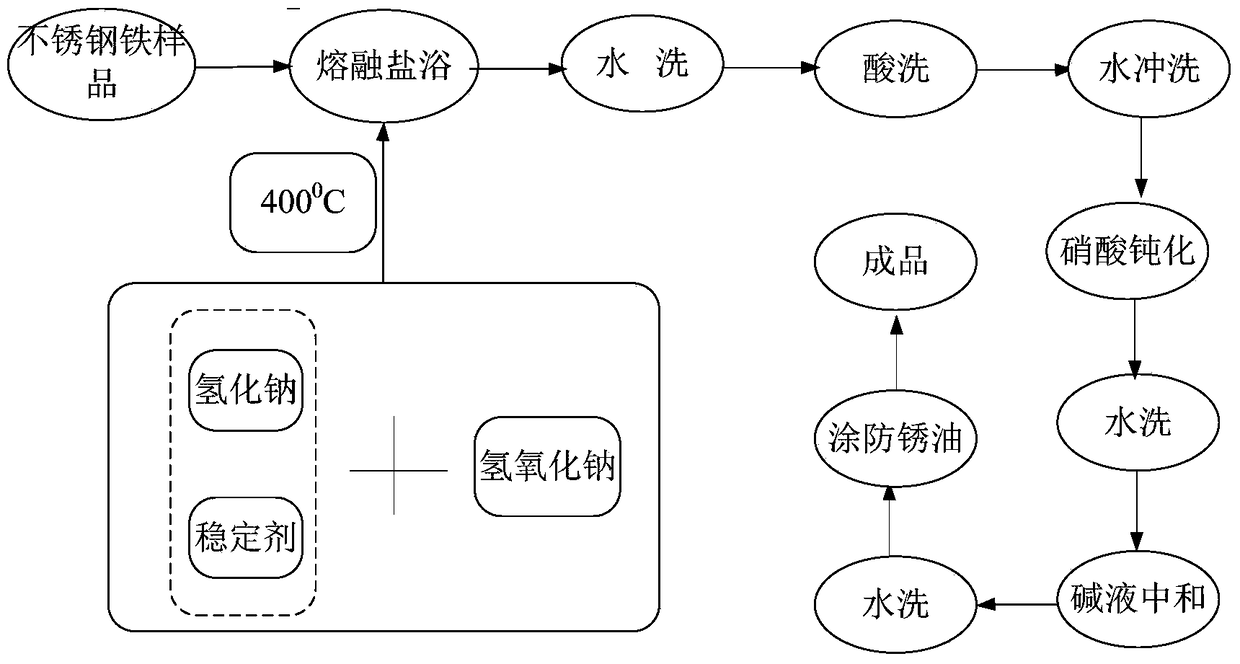

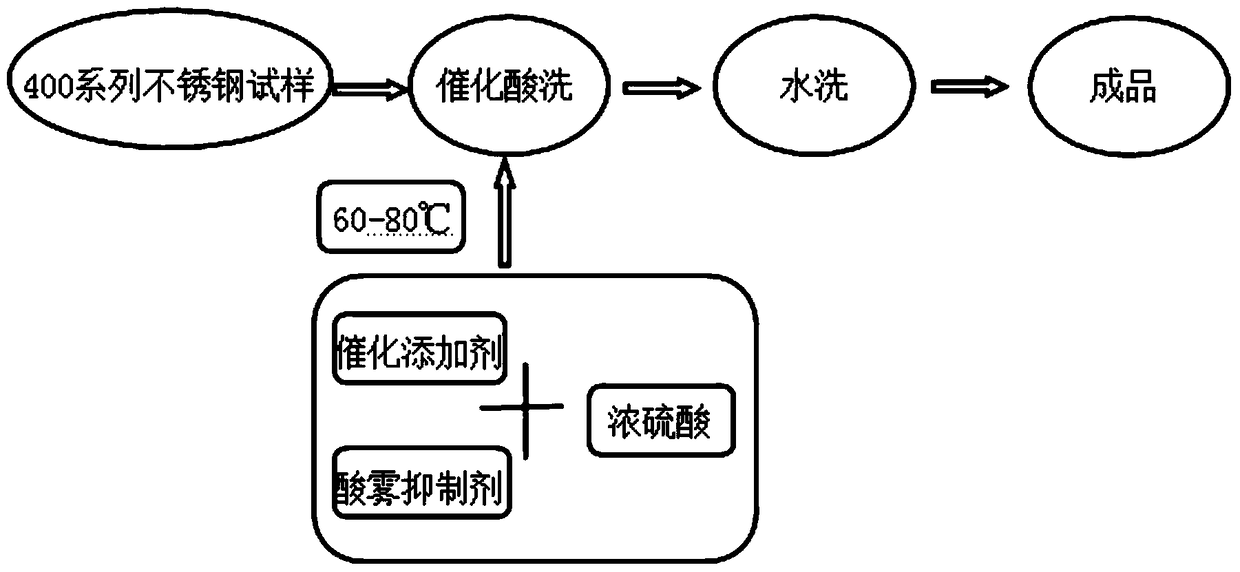

Method used

Image

Examples

Embodiment 1

[0035] 400 series stainless steel annealed wire, grade 1Cr18Ni9, carbon content <0.15%, phosphorus content <0.015, sulfur content <0.03%. Specification: 5.0mm-40mm, annealing temperature 750-850℃.

[0036]The pickling solution is composed of concentrated sulfuric acid, catalytic additives, acid mist inhibitors and water. The mass ratio of each substance is as follows: concentrated sulfuric acid concentration is 18wt%, sodium fluoride is 3.0wt%, potassium persulfate is 4.0wt%, EDTA is 1.5wt%, acid mist inhibitor is 0.3wt% urotropine+0.5wt% Sodium chloride+0.1wt% sodium lauryl sulfate, and the balance is water.

[0037] Pickling method: inject the prepared pickling solution into the pickling tank, and directly immerse the stainless steel annealed wire in the pickling solution for pickling. The pickling temperature is 70°C, and the pickling time is 35 minutes. After pickling, take out the stainless steel annealed wire and rinse it with water.

[0038] The surface of the stain...

Embodiment 2

[0040] 400 series stainless steel pipes, grade 0Cr18Ni9, carbon content <0.07%, phosphorus content <0.035, sulfur content <0.03%. Specification: 5.0mm-40mm, annealing temperature 820-950℃.

[0041] The pickling solution is composed of concentrated sulfuric acid, catalytic additives, acid mist inhibitors and water. The mass ratio of each substance is as follows: concentrated sulfuric acid concentration is 12wt%, sodium fluoride is 2.0wt%, potassium persulfate is 3.0wt%, EDTA is 1.0wt%, acid mist inhibitor is 0.2wt% urotropine+0.3wt% Sodium chloride+0.1wt% sodium lauryl sulfate, and the balance is water.

[0042] Pickling method: inject the prepared pickling solution into the pickling tank, and directly immerse the stainless steel annealed wire in the pickling solution for pickling. The pickling temperature is 75°C, and the pickling time is 50 minutes. After pickling, take out the stainless steel annealed wire and rinse it with water.

[0043] The surface of the stainless st...

Embodiment 3

[0045] 400 series stainless steel annealed wire rod, grade 0Cr25Ni20, carbon content <0.08%, phosphorus content <0.035, sulfur content <0.03%. Specification: 5.0mm-40mm, annealing temperature 770-820℃.

[0046] The pickling solution is composed of concentrated sulfuric acid, catalytic additives, acid mist inhibitors and water. The mass ratio of each substance is as follows: concentrated sulfuric acid concentration is 15wt%, sodium fluoride is 3.0wt%, potassium persulfate is 3.0wt%, EDTA is 1.5wt%, acid mist inhibitor is 0.2wt% urotropine+0.4wt% Sodium chloride+0.1wt% sodium lauryl sulfate, and the balance is water.

[0047] Pickling method: inject the prepared pickling solution into the pickling tank, and directly immerse the stainless steel annealed wire in the pickling solution for pickling. The pickling temperature is 75°C, and the pickling time is 45 minutes. After pickling, take out the stainless steel pipe and rinse it with water.

[0048] The surface of the stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com