Coated modified LiNi<0.7>Co<0.1>Mn<0.2>O<2> ternary anode material and preparation method thereof and battery

A positive electrode material and modification technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as loss of lithium ions, high valence to reduce valence changes, slurry to gel, etc., to achieve improved cycle performance, The effect of increasing the void

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

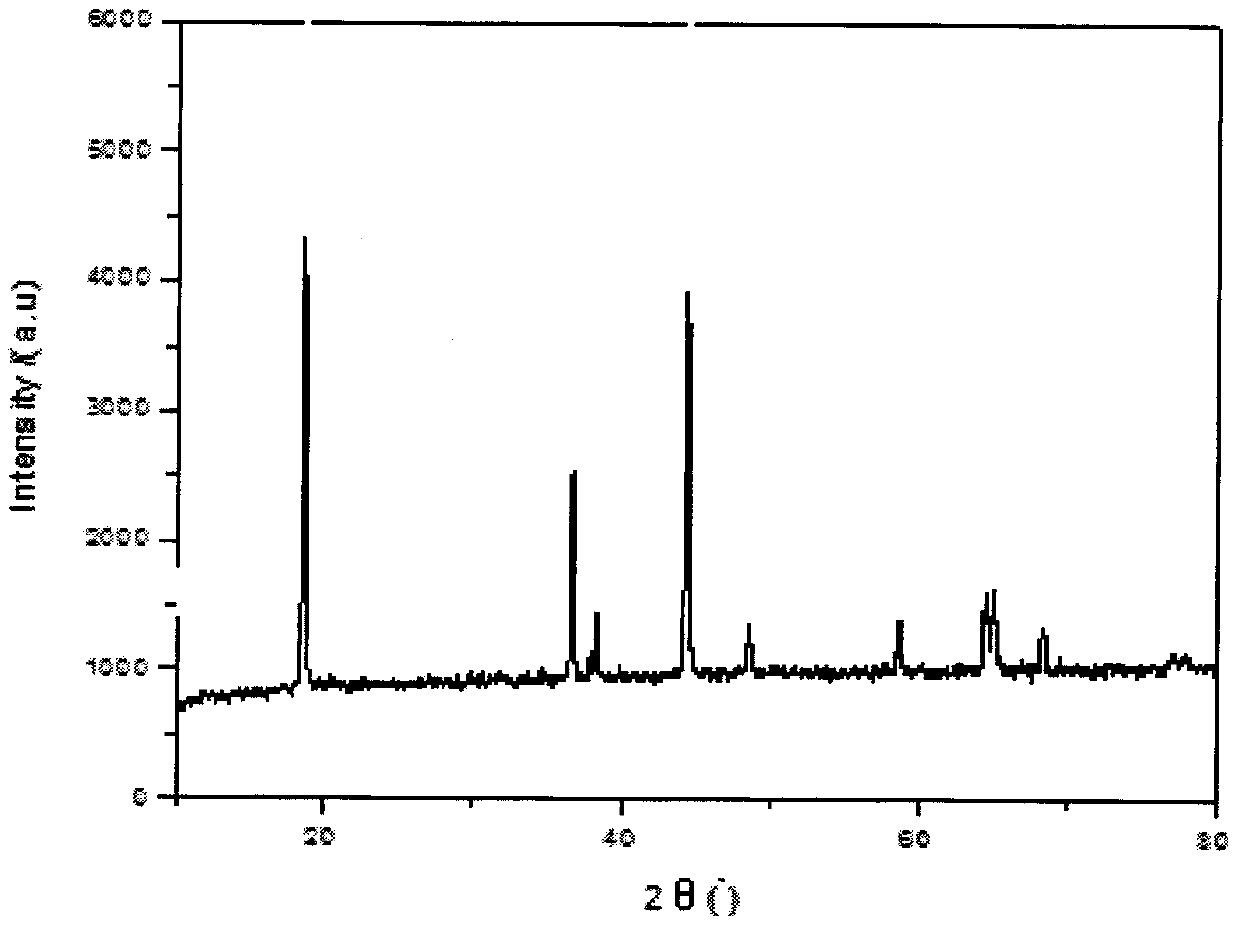

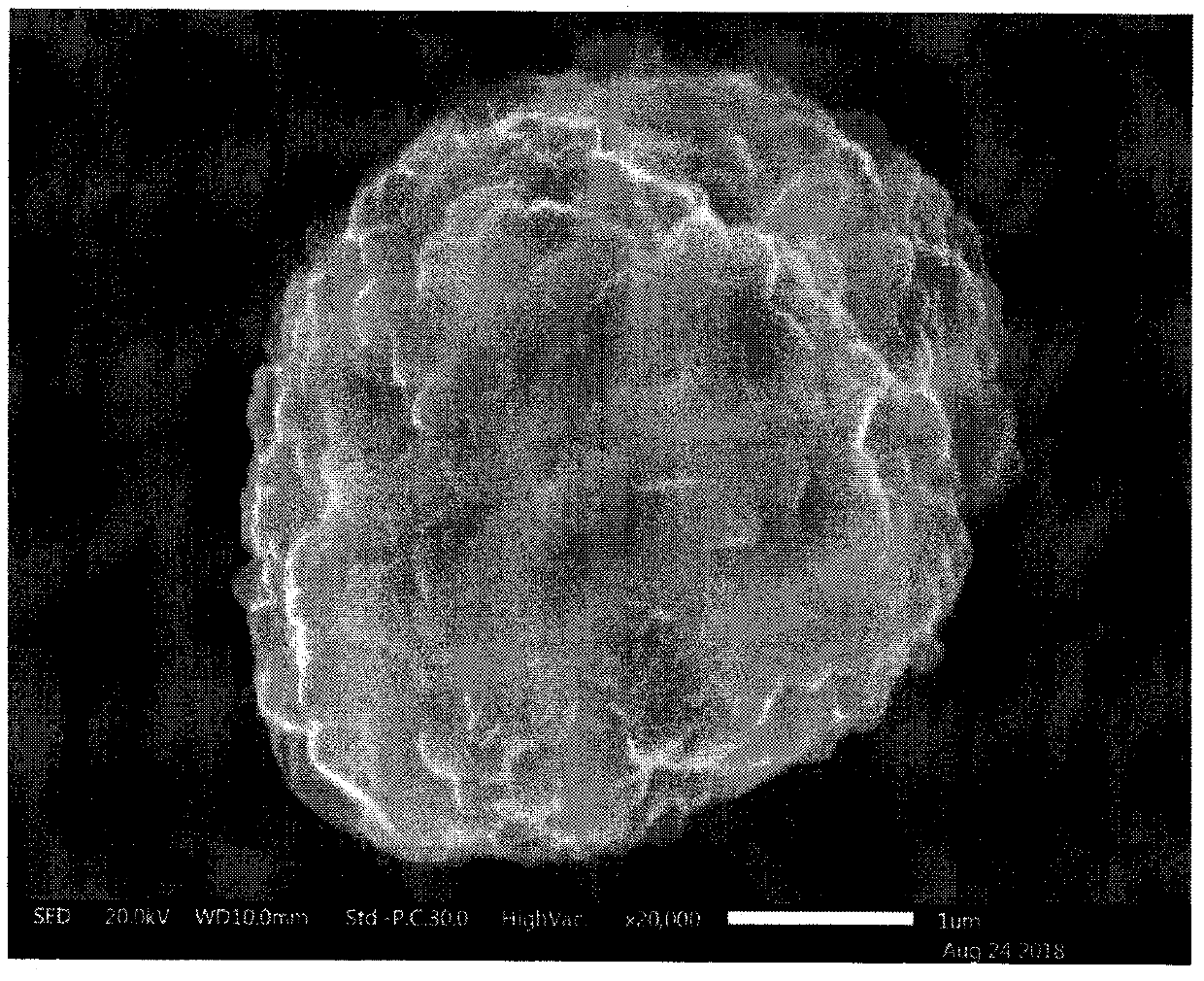

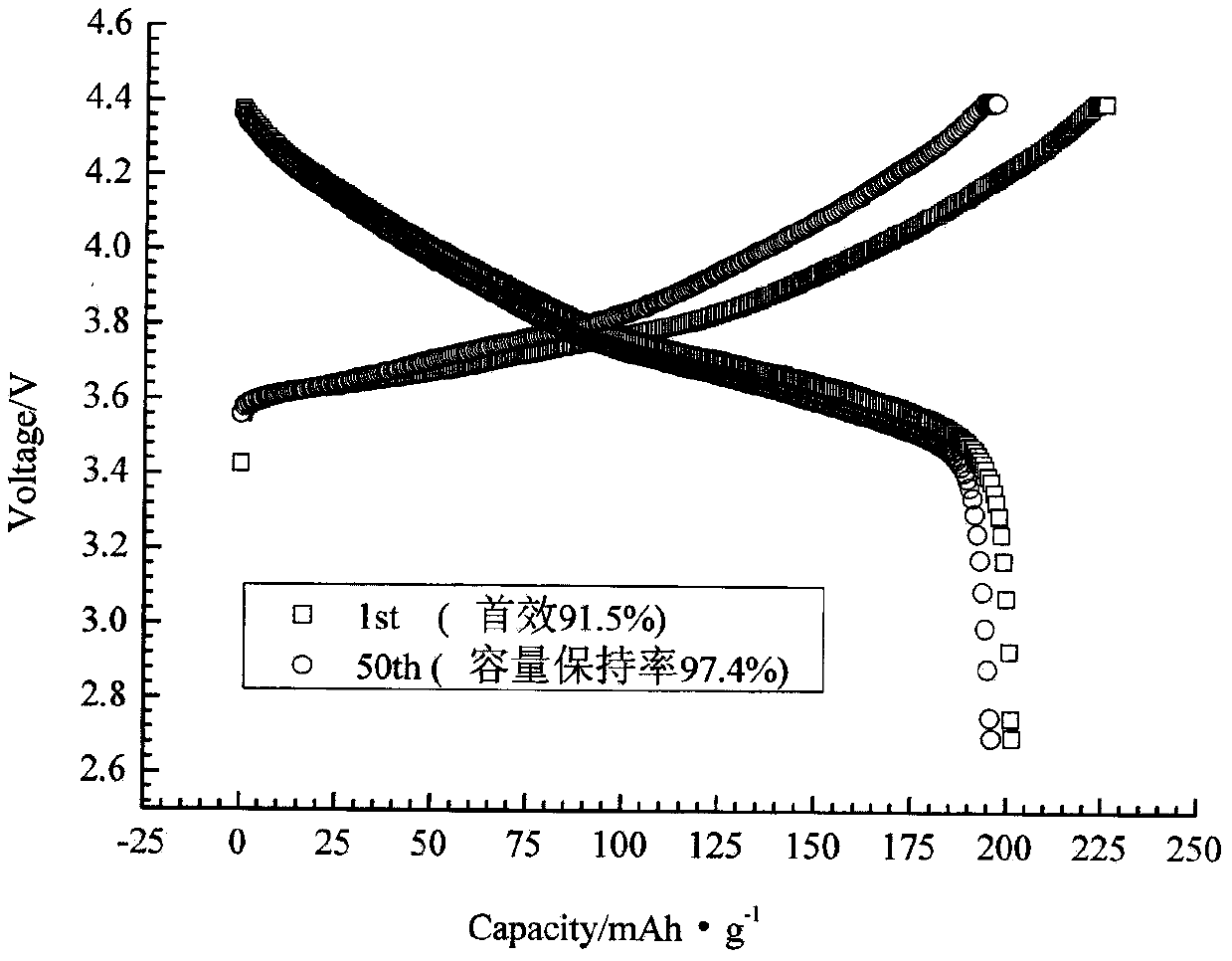

Image

Examples

Embodiment 1

[0047] 1) Preparation of nickel cobalt manganese hydroxide precursor:

[0048] 1.1) get nickel sulfate, cobalt sulfate and manganese sulfate to be dissolved in water, obtain the first mixed solution, control the concentration of total metal ion in the first mixed solution to be 2mol / L, and the mol ratio of nickel ion, cobalt ion and manganese ion is 7:1:2;

[0049] 1.2) adding magnesium sulfate to the mixed solution, dissolving to obtain the second mixed solution; wherein the added amount of magnesium sulfate is 0.1% of the total molar weight of nickel ions, cobalt ions and manganese ions;

[0050] 1.3) adding precipitating agent and complexing agent to carry out co-precipitation reaction in the second mixed solution, wherein:

[0051] The total time of the designed co-precipitation reaction is 6h, and the co-precipitation reaction process includes two stages, respectively the first reaction stage and the second reaction stage, wherein the reaction time of the first reaction st...

Embodiment 2

[0077] 1) Preparation of nickel cobalt manganese hydroxide precursor:

[0078] 1.1) get nickel sulfate, cobalt sulfate and manganese sulfate to be dissolved in water, obtain the first mixed solution, control the concentration of total metal ion in the first mixed solution to be 2mol / L, and the mol ratio of nickel ion, cobalt ion and manganese ion is 7:1:2;

[0079] 1.2) adding magnesium sulfate to the mixed solution, dissolving to obtain the second mixed solution; wherein the added amount of magnesium sulfate is 0.2% of the total molar weight of nickel ions, cobalt ions and manganese ions;

[0080] 1.3) adding precipitating agent and complexing agent to carry out co-precipitation reaction in the second mixed solution, wherein:

[0081] The total time of the designed co-precipitation reaction is 6h, and the co-precipitation reaction process includes two stages, respectively the first reaction stage and the second reaction stage, wherein the reaction time of the first reaction ...

Embodiment 3

[0092] 1) Preparation of nickel cobalt manganese hydroxide precursor:

[0093] 1.1) get nickel sulfate, cobalt sulfate and manganese sulfate to be dissolved in water, obtain the first mixed solution, control the concentration of total metal ion in the first mixed solution to be 2mol / L, and the mol ratio of nickel ion, cobalt ion and manganese ion is 7:1:2;

[0094] 1.2) adding magnesium sulfate to the mixed solution, dissolving to obtain the second mixed solution; wherein the added amount of magnesium sulfate is 0.08% of the total molar weight of nickel ions, cobalt ions and manganese ions;

[0095] 1.3) adding precipitating agent and complexing agent to carry out co-precipitation reaction in the second mixed solution, wherein:

[0096] The total time of the designed co-precipitation reaction is 6h, and the co-precipitation reaction process includes two stages, respectively the first reaction stage and the second reaction stage, wherein the reaction time of the first reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com