Measurement apparatus and method for monitoring clearance generated by air preheater by using double laser

A measurement device, laser measurement technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problem of reducing the cooling requirements of laser measurement equipment, difficult to eliminate high temperature interference and influence, etc., to achieve simple structure and increased working life , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

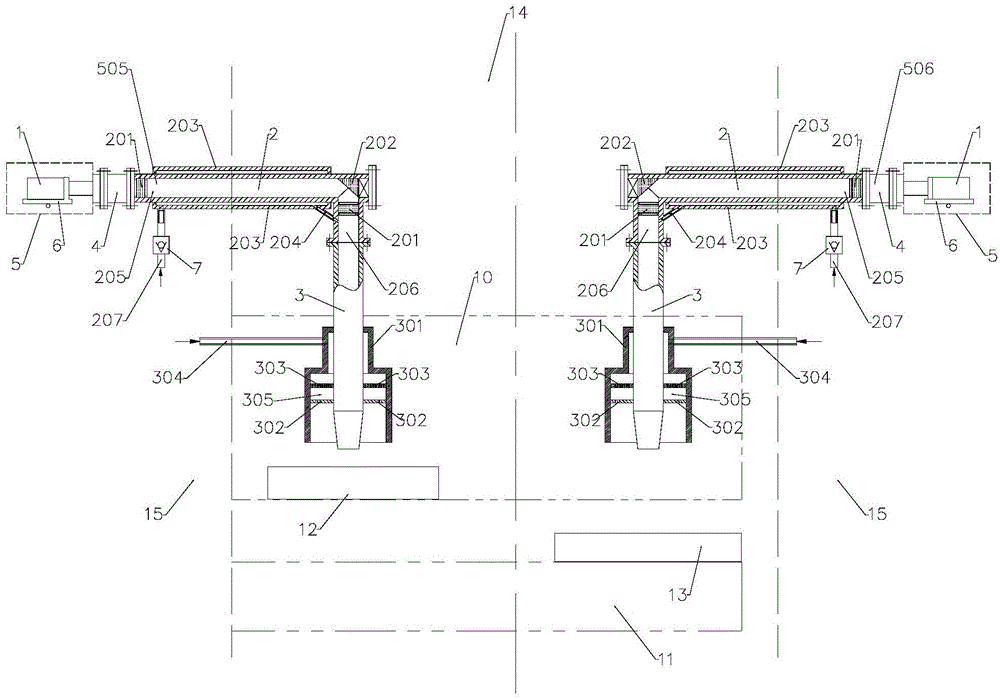

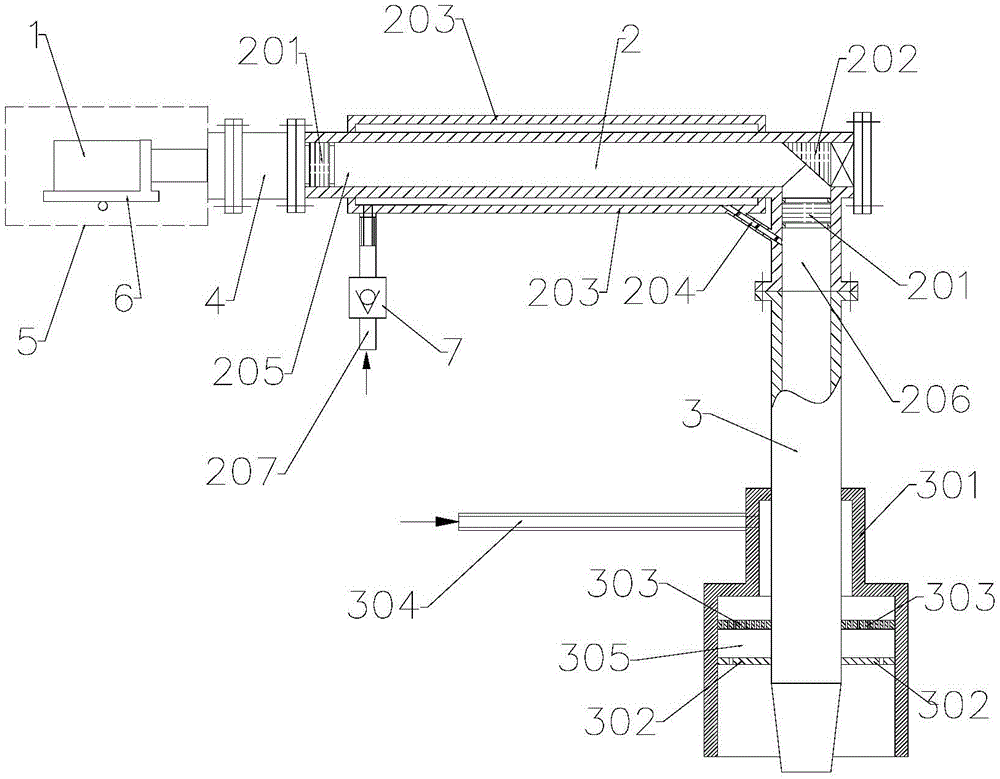

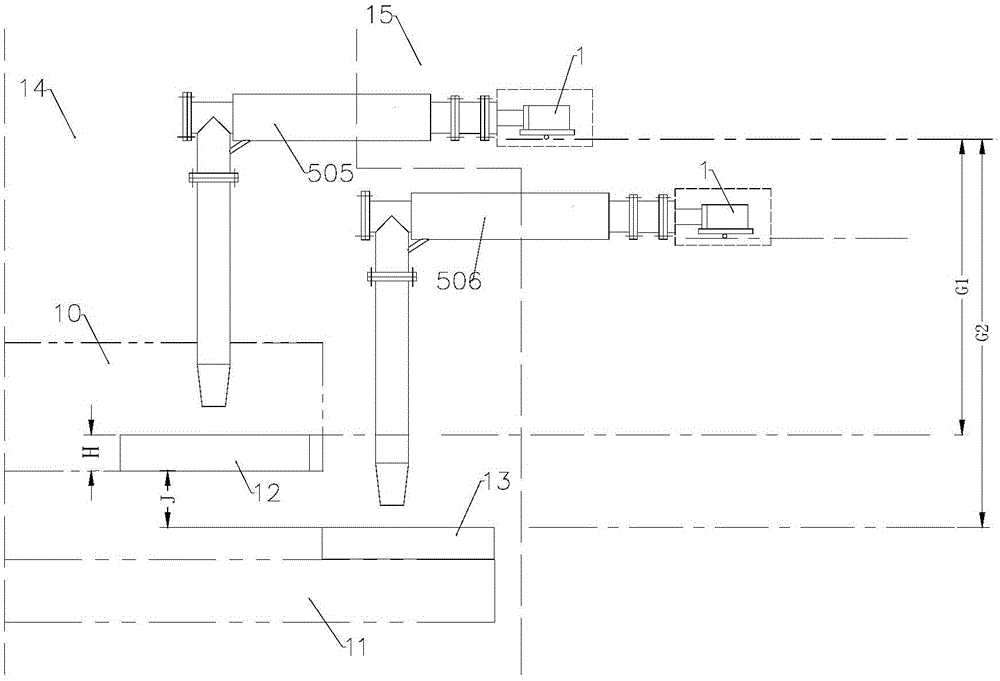

[0034] Such as Figure 1 to 3 As shown, a measuring device using dual lasers to monitor the gap of the air preheater includes two identical laser measuring mechanisms 505 and 506 arranged laterally next to the sector plate 10, specifically, it consists of a first laser measuring mechanism 505 and The second laser measuring mechanism 506 is composed. Each laser measuring mechanism 505, 506 includes a laser ranging sensor 1 arranged on the outside 15 of the air preheater, an optical axis refraction lens barrel 2 passing through the outer wall of the air preheater 14, and an optical axis refraction lens barrel 2 opposite to the optical axis refraction lens barrel 2 Center air duct 3.

[0035] Wherein, a protective component 5 and a position adjuster 6 for installing the laser distance measuring sensor 1 are provided outside the laser distance measuring sensor 1. The optical axis refracting lens barrel 2 is connected with the position adjuster 6 through the transition piece 4. The ...

Embodiment 2

[0049] Such as Figure 3 to 5 As shown, a measurement method using dual lasers to monitor the gap of the air preheater, which uses the measuring device as in Example 1 to measure and calculate the gap value between the sector plate and the rotor, includes the following steps: aligning two laser measuring mechanisms , Horizontally and next to each other, they are installed at the same height, and the positions of the two laser measuring sensors are adjusted and calibrated. The measured value of the sector plate at the mechanical zero position under cold conditions is taken as the initial displacement value of the sector plate, and the sector plate position corresponding to this value is recorded as the starting zero point of the sector plate's absolute displacement. The current absolute displacement value of the sector plate refers to The displacement change amount relative to the starting zero point of the absolute displacement. Under cold conditions, the measured value of the...

Embodiment 3

[0054] In the cold state of the air preheater, the absolute displacement of the sector plate 10 is at the mechanical zero position, and the initial deformation of the air preheater rotor 11 is zero. At this time, the measurement results of the two laser distance measuring sensors 1 are respectively calibrated to the initial values of the zero position of the deformation amount and the displacement amount and are included in the respective measurement mechanisms. When the hot rotor of the air preheater deforms or the sector plate is displaced, the difference between the current value of the rotor deformation and the current value of the sector plate displacement measured by the two laser ranging sensors 1 is the gap value. The rest is the same as in Example 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap