Bright spot detecting equipment and method for filtering foreign body noise

A technology for detecting equipment and bright spots, which is applied in the direction of testing optical performance, etc., can solve problems such as misjudgment in the detection process, and achieve the effect of improving the filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The detailed description and technical content of the present invention will now be described in conjunction with the drawings as follows. Furthermore, for the convenience of description, the figures in the present invention are not necessarily drawn according to actual proportions, but are exaggerated. These figures and their proportions are not intended to limit the scope of the present invention.

[0047] The present invention provides a bright spot detection device for filtering foreign body noise. The bright spot detection device is used for high-precision optical instrument detection, using machine vision (detection lens) as the detection standard to process and obtain panels or polarized light. The location of foreign objects or pattern flaws on the film.

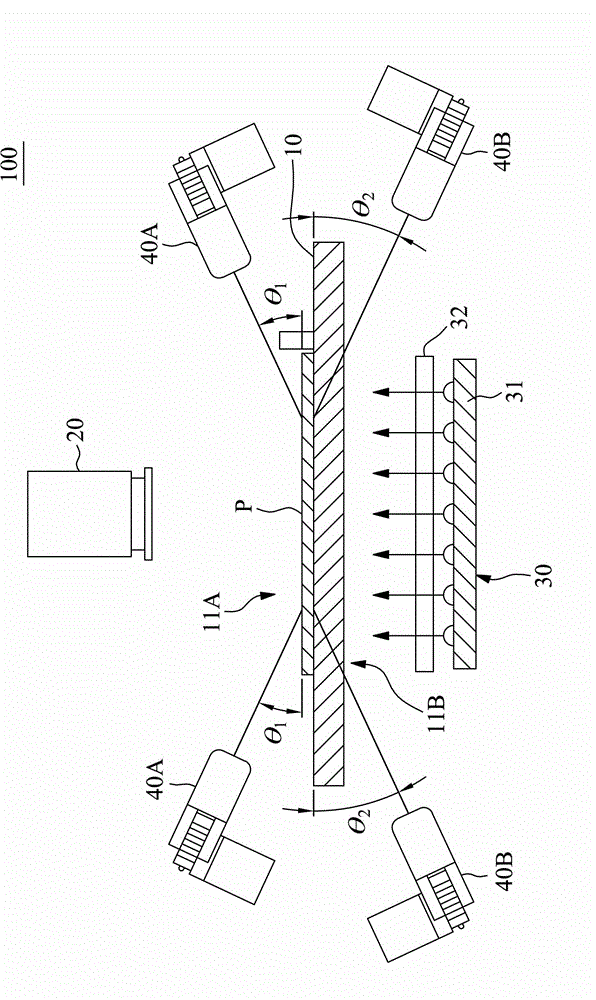

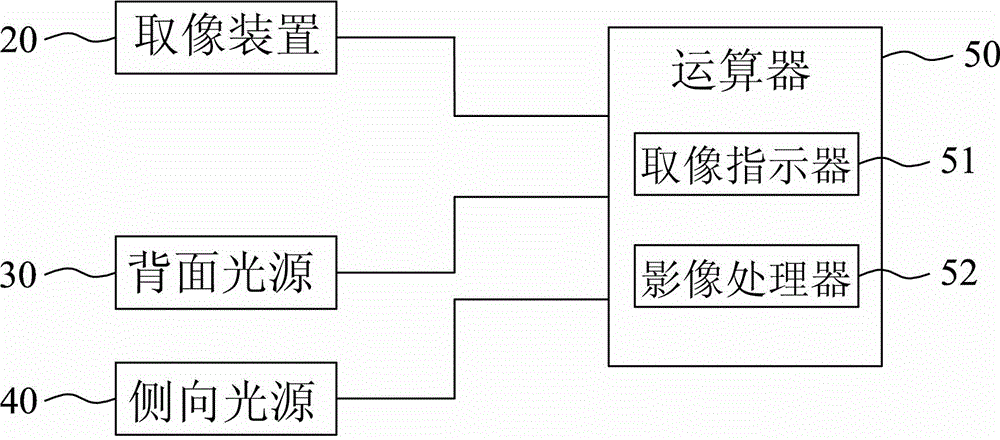

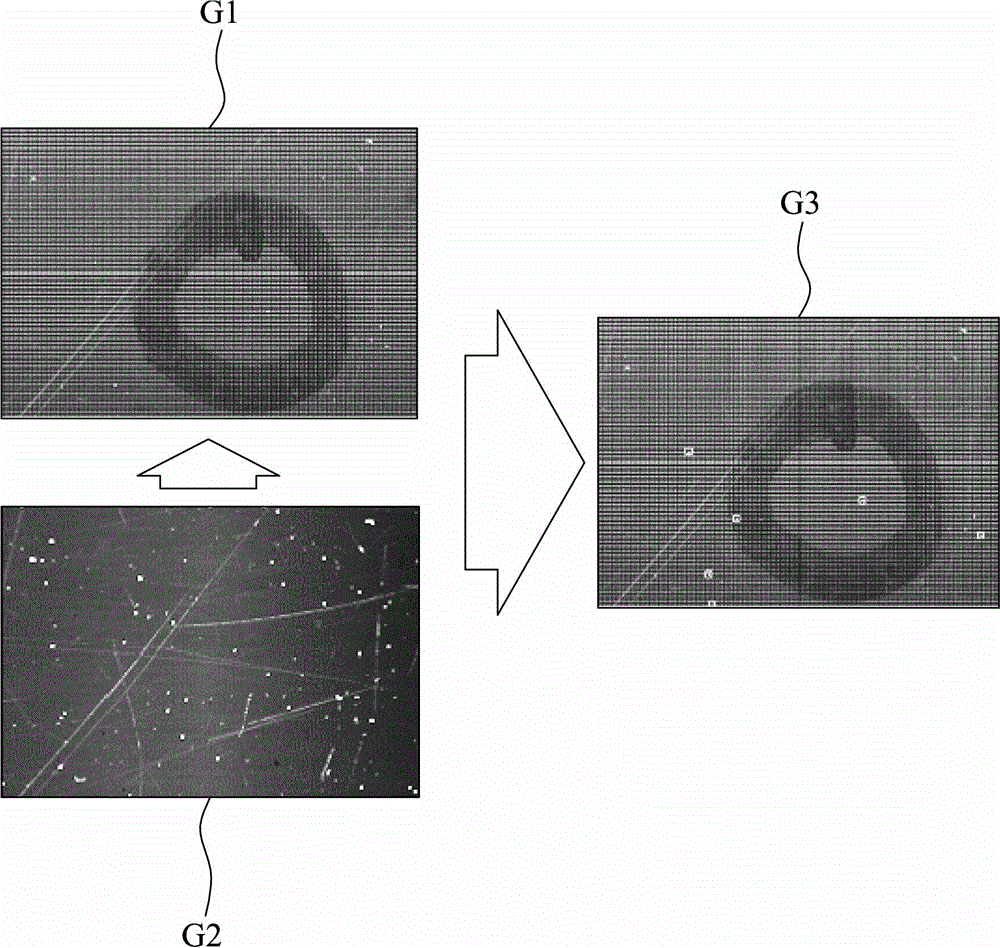

[0048] See figure 1 and figure 2 , Is the side view and block diagram of the bright spot detection equipment of the present invention, as shown in the figure:

[0049] The present invention provides a bright spot d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com