Combined hardness measuring instrument

A measuring instrument and combined technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of incorrect distribution of sensors, poor measurement accuracy, manual driving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

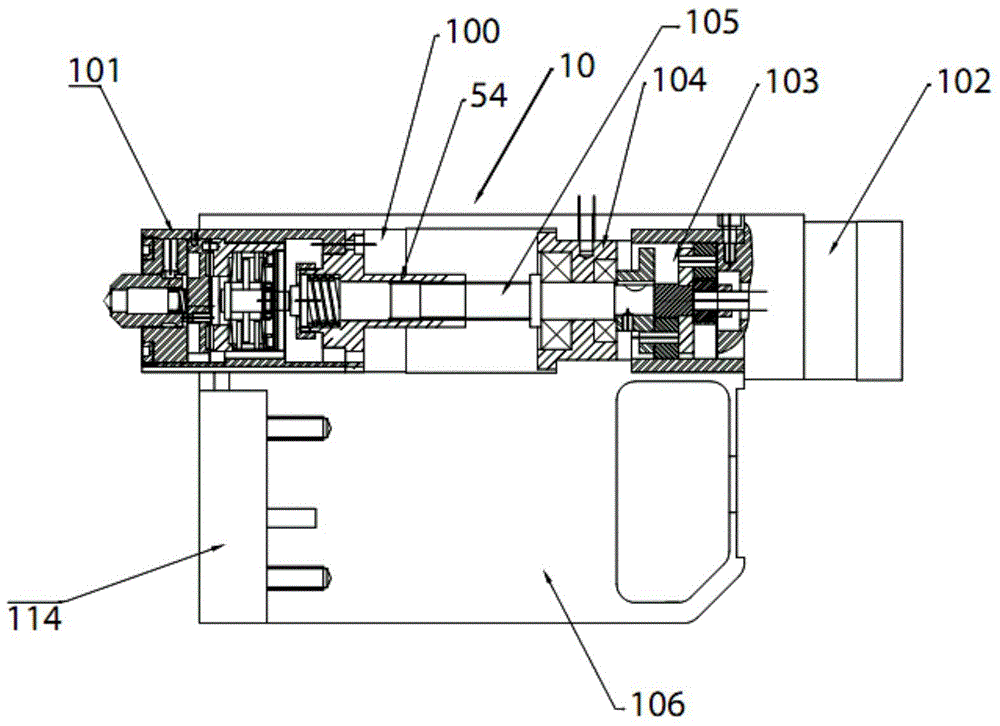

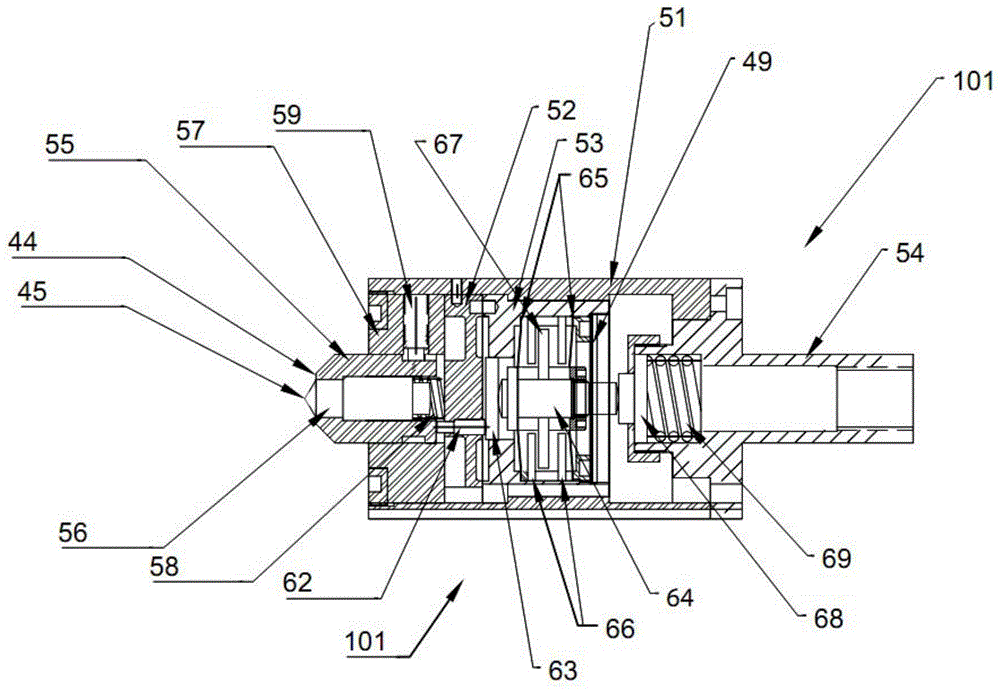

[0056] Refer below Figure 1 to Figure 12 The specific implementation of the combined hardness measuring instrument of the present invention will be described in detail.

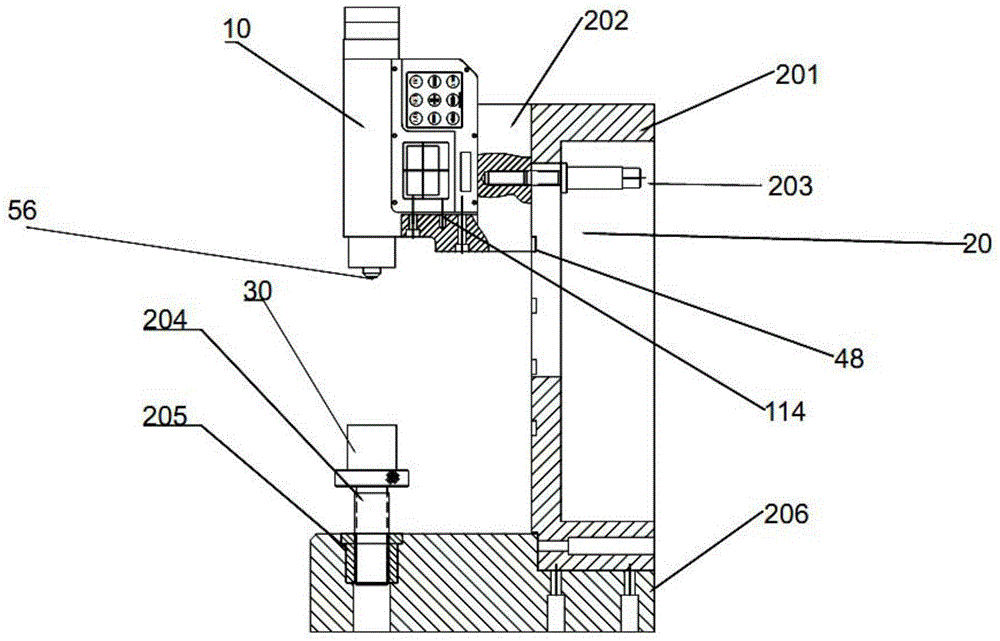

[0057] The combined hardness measuring instrument of the present invention includes a measuring body 10 and a set of frames that can be connected with the measuring body 10 . figure 1 Shown is a hardness tester consisting of a measuring body 10 and a cylindrical frame 20 . like figure 1 As shown, the column frame 20 is composed of a box member 201 , a connecting plate 202 , a screw 203 , an anvil 204 , a second nut 205 and a base 206 . The measuring body 10 is fixed on the frame 20 through the connecting plate 202 . Equidistant grooves 48 are formed on the box-shaped member 201 , and a positioning key is provided on the connecting plate 202 , and the connecting plate 202 is inserted into any equidistant groove 48 through the positioning key and fixed on the box-shaped member 201 with screws 203 . The anv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com