Spiral multifunctional test device and method for physical properties of materials

A testing device and physical property technology, which is applied in the field of spiral multifunctional material physical property testing device, can solve the problems of result error and low test accuracy, and achieve the effect of reducing displacement error and ensuring volume accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

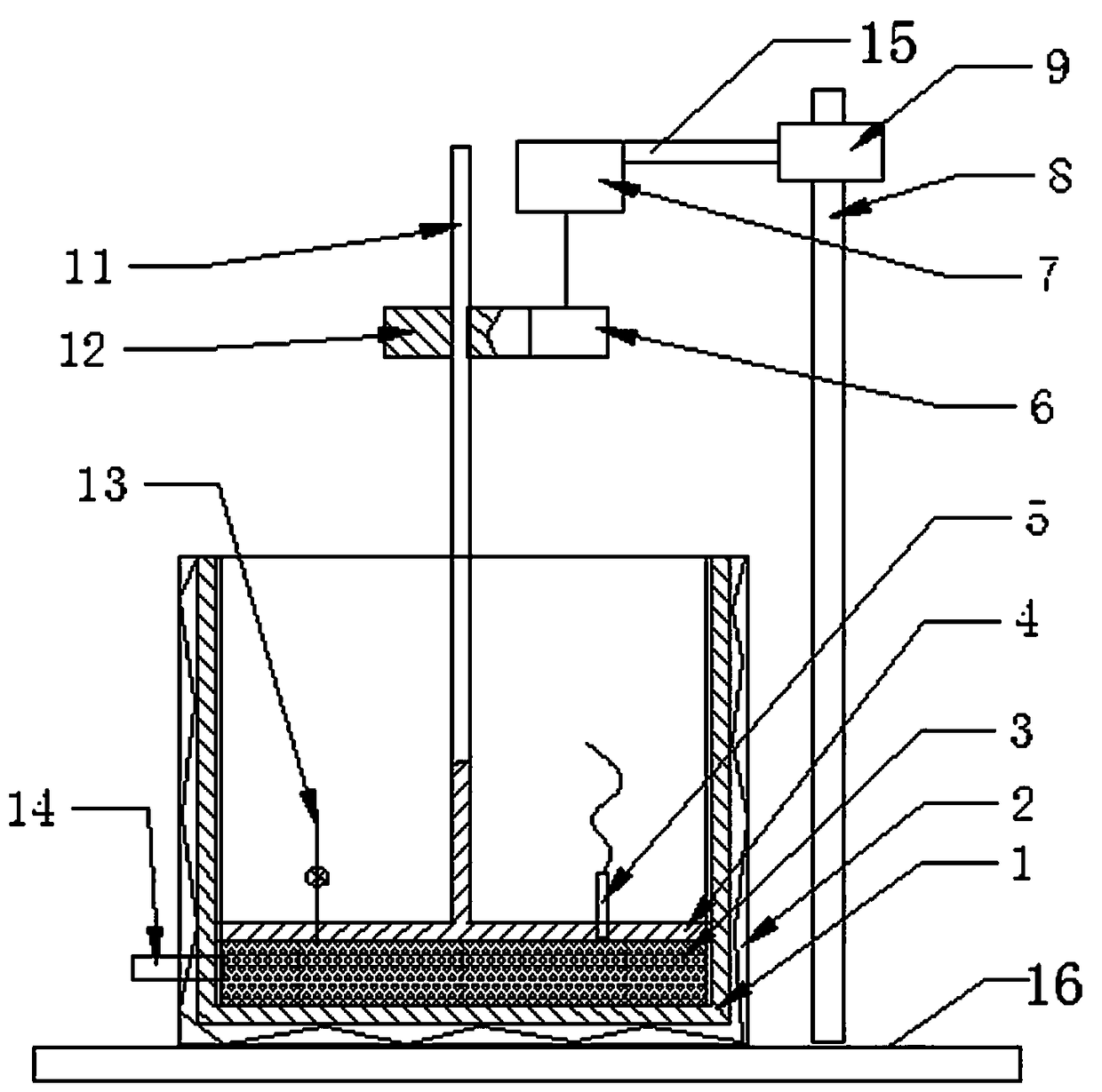

[0037] This embodiment provides a spiral multifunctional material physical property testing device.

[0038] like figure 1 As shown, a spiral multifunctional material physical property testing device includes a container 1, which is a cylindrical container with an internal thread, and its material can be metal, ceramics, glass, etc., preferably metal. The outer surface of the container 1 is a heater 2, and the heating method can be resistance heating, infrared heating, water, oil bath heating, etc., and resistance heating is preferred in this embodiment.

[0039] The outer surface of the piston 4 is threaded, which cooperates with the inner thread of the container 1. Through the rotation of the piston, the piston 4 can move up and down in the container 1, so as to apply pressure to the material and adjust the volume, and has good sealing performance. The piston 4 is equipped with an exhaust valve 13, which can discharge gas smoothly. When the valve of the exhaust valve 13 is ...

Embodiment 2

[0047] This embodiment provides a test method of a spiral high-precision multifunctional material physical property testing device in Example 1, and the specific steps are as follows:

[0048] S1. First weigh material 3 of a certain quality, add it to container 1, start heater 2, heat material 3, and make it melt into a melt;

[0049] S2. Start the drive source 7, make the external thread of the piston 4 cooperate with the internal thread of the container 1 to rotate and descend, open the exhaust valve 13, and when the piston 4 descends to the surface of the melt and contacts the melt, turn off the drive source 7 and close the exhaust valve 13. Collect initial data such as temperature, pressure, and displacement of the material 3 through the sensor 5 and the measuring device;

[0050] S3. Start the driving source 7 to make the piston 4 continue to descend, the melt pressure of the material 3 increases, and collect the material pressure, temperature, and volume data; wherein, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com