Pixel circuit and driving method thereof as well as display apparatus

A pixel circuit and capacitor technology, applied in the field of display devices, can solve the problems of incomplete discharge of the storage capacitor 22, difficulty in accurately determining the programming time, etc., and achieve the effect of compensating for threshold voltage shift and taking into account speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

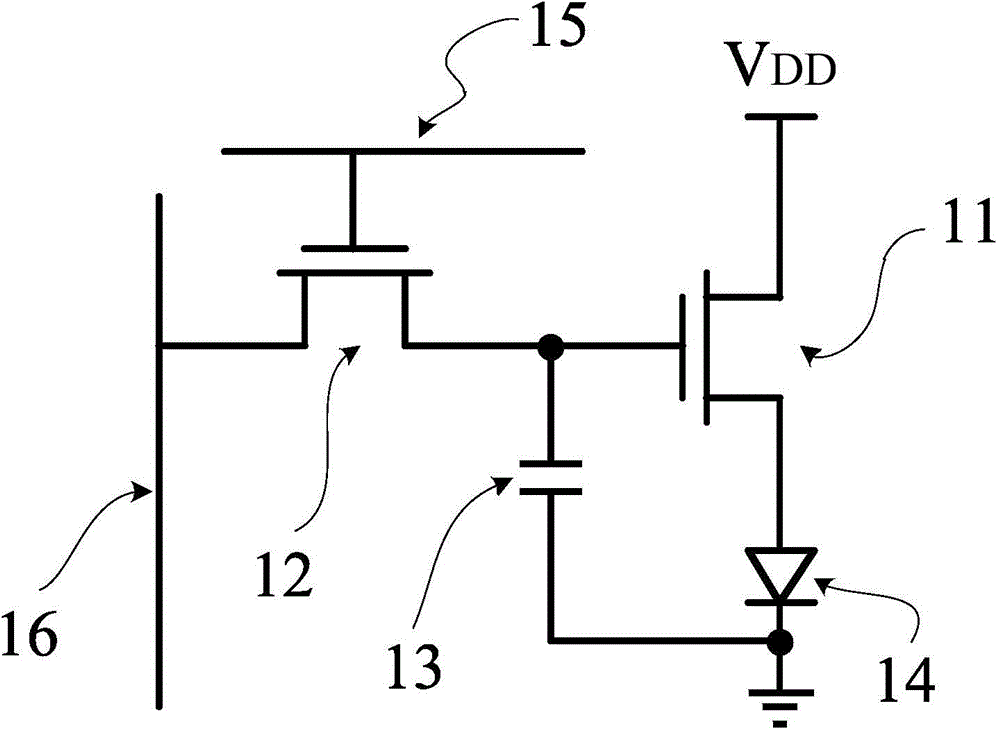

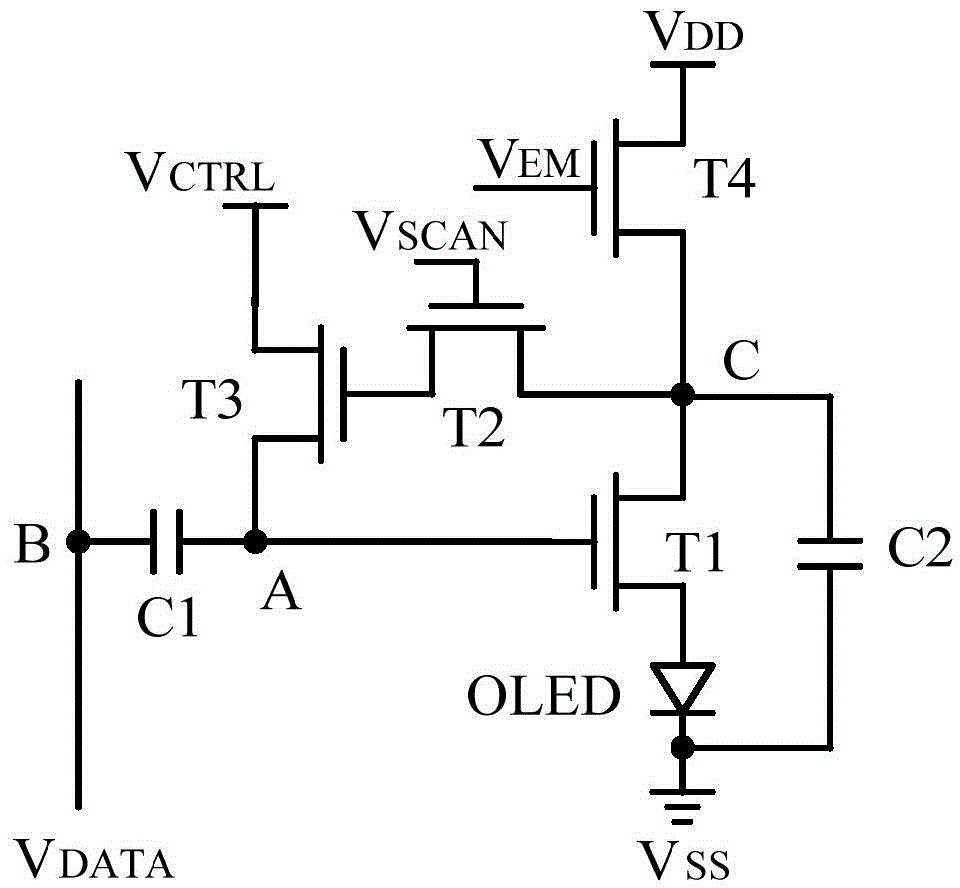

[0044] Please refer to image 3 , image 3 Shown is the structure of an embodiment of the pixel circuit of the present application, including: a first capacitor C1, a second capacitor C2, a second transistor T2, a third transistor T3, and a capacitor for coupling between the first common electrode VDD and the second common electrode Lighting branch between VSS. The light emitting branch circuit includes a first transistor T1, a fourth transistor T4 and a light emitting element OLED connected in series.

[0045] Wherein, the first pole of the first transistor T1 is coupled to the second pole of the fourth transistor T4, and the coupling node is the third node C; the control pole of the fourth transistor T4 is used to input the second scanning control signal V EM , the fourth transistor T4 responds to the second scan control signal V EM Switch the on and off state of the light-emitting branch.

[0046] The first end of the first capacitor C1 is the second node B for coupling...

Embodiment 2

[0070] The circuit provided by Embodiment 1 adopts a concentrated light emitting method. For a display device, it needs to wait for the data signals of all rows of pixel arrays to be written before entering the light emitting stage. It is advisable to set the number of rows of the pixel array as n(n is a positive integer), when the kth (k≤n, positive integer) row pixel programming stage is completed, it is necessary to wait for the k+1 to nth row pixel programming to be completed, and the pixel array enters the light emitting stage at the same time. With the concentrated light emitting method, the light emitting time of the pixel array is short and the current required is large, which may accelerate the degradation of the light emitting element OLED.

[0071] To this end, this embodiment discloses a pixel circuit of non-concentrated light emitting mode, please refer to Figure 6 and Figure 7 , is the structure of the pixel circuit in this embodiment. The difference from the ...

Embodiment 3

[0091] Please refer to Figure 9 and Figure 10 , which is the structural diagram of the pixel circuit disclosed in this embodiment. The difference from the above-mentioned embodiments is that the pixel circuit disclosed in this embodiment further includes a fifth transistor T5, and the first pole and the second pole of the fifth transistor T5 are connected in parallel to the light-emitting element Both ends of the OLED, the gate is used to input the first scan control signal V SCAN .

[0092] When the light-emitting element OLED is in a non-light-emitting state, the fifth transistor T5 is turned on, and when the light-emitting element OLED is in a light-emitting state, the fifth transistor T5 is turned off. Specifically: in the initialization stage and the programming stage, the fifth transistor T5 responds to the first scanning control signal V SCAN The high level is turned on; in the light emitting stage, the fifth transistor T5 responds to the first scanning control sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com