Automatic adjustment method of grinding wheel position of drill edge grinder, its device and driving device

An automatic adjustment device and automatic adjustment technology are applied to the parts of boring machine/drilling machine, drilling tool accessories, drilling/drilling equipment, etc., which can solve the problems of inconvenient, difficult to grasp the accuracy, and hinder the working efficiency of the grinding machine. Achieve the effect of improving accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] first look figure 2 Shown, reveals the flowchart of the preferred embodiment of the present invention, and coordinates Figure 1a , Figure 1d , image 3 , Figure 4 and Figure 8 The method for automatically adjusting the position of the grinding wheel of the drill grinder of the present invention includes the following implementation steps:

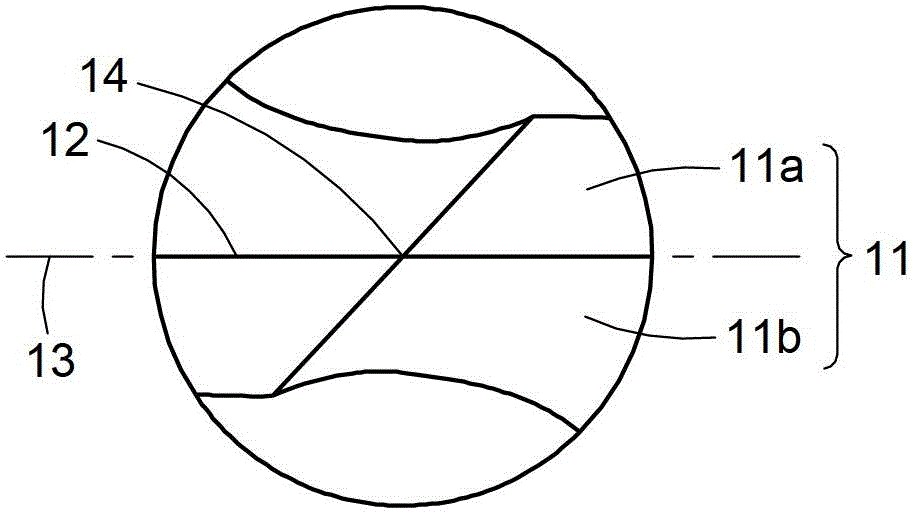

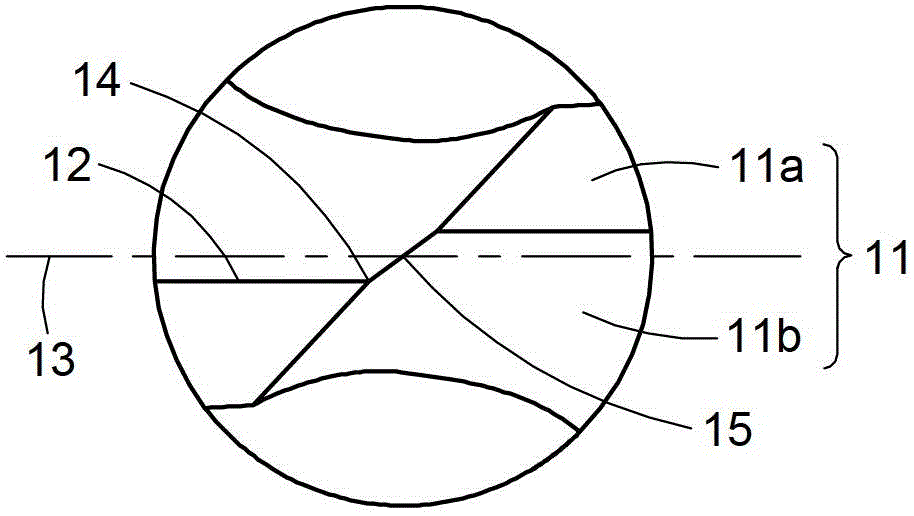

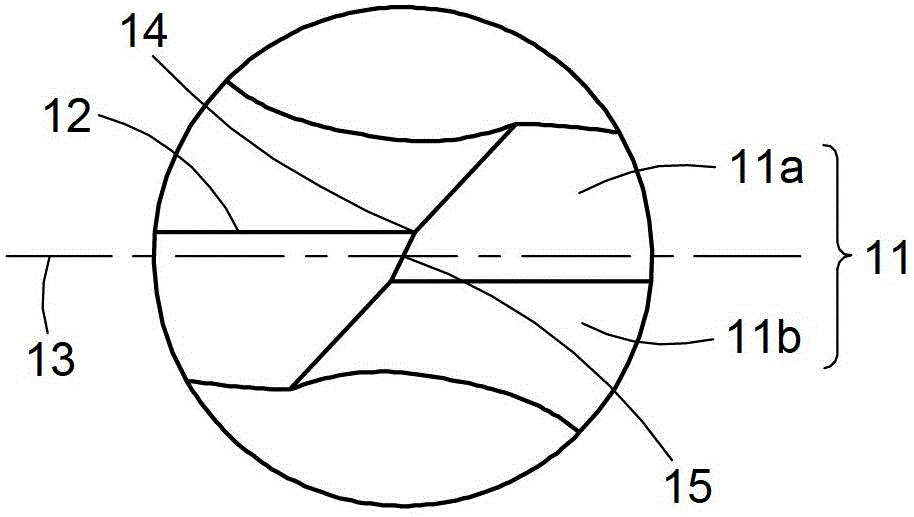

[0041] In step S11, a charge-coupled device 41 is used to detect a bevel line 12 offset v of a drill face 11 (such as Figure 8 and Figure 1d shown). Wherein the drill edge face 11 comprises a first edge face 11a and a second edge face 11b (such as Figure 1a shown). The edge line 12 is located at the junction of the first edge surface 11a and the second edge surface 11b, and the offset v of the edge edge line 12 is the deviation between the edge edge line 12 and a reference line 13 of the edge edge. displacement (such as Figure 1d shown). Furthermore, the charge-coupled device 41 may include a CCD imaging unit, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com