Compensating clutch with spacer elements

A clutch and component technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve problems such as high clutch consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

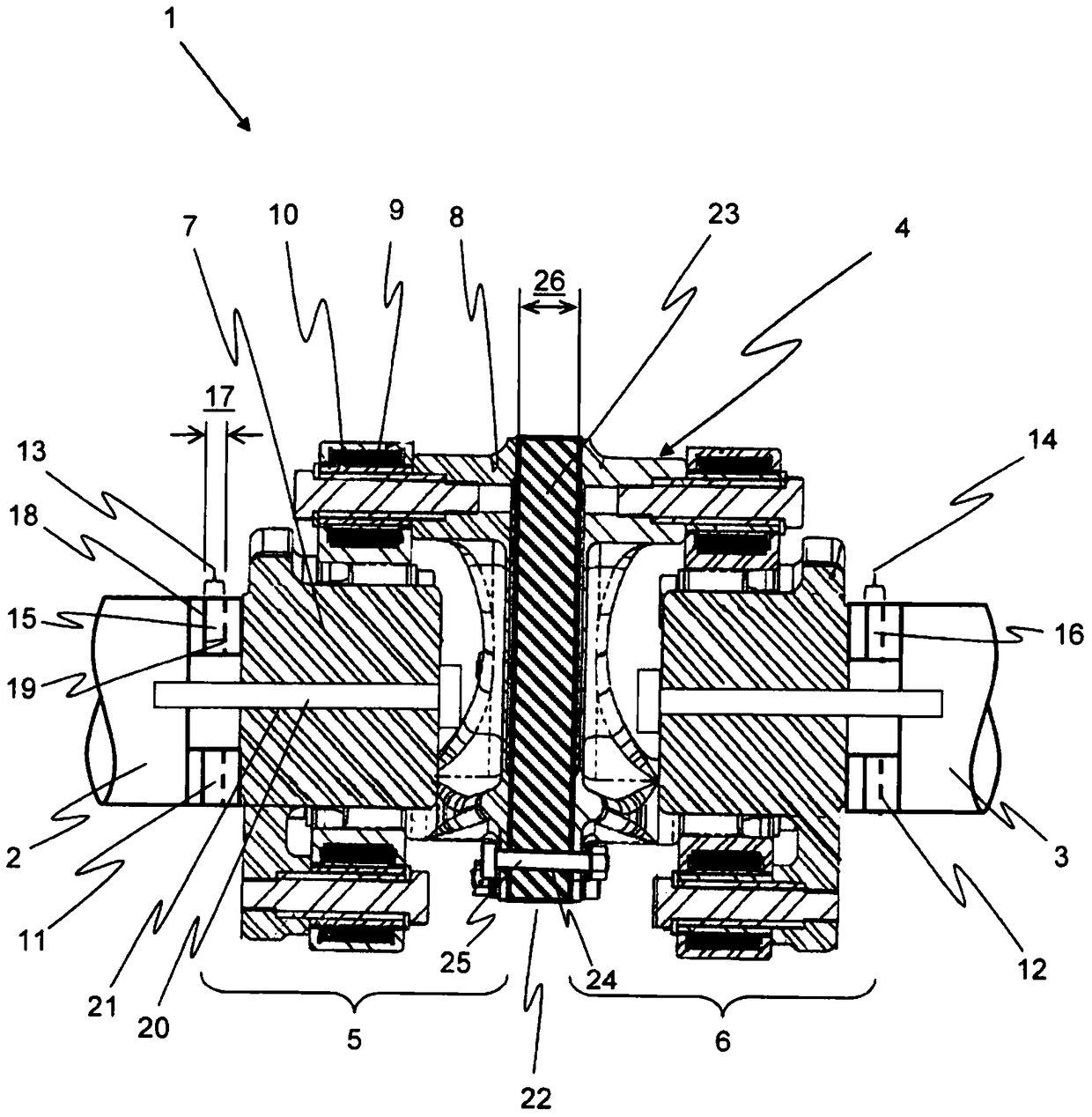

[0029] figure 1 The clutch device 1 is shown in longitudinal section. The clutch arrangement comprises first and second shafts 2 , 3 , which are connected to one another in a rotationally fixed and offset-compensating manner via an interposed compensating clutch 4 . Such clutch devices 1 are found in particular in drive trains of rail vehicles. The clutch device is arranged between the drive unit (not shown here) and the transmission unit. In this case, the drive unit is connected to a spring-mounted bogie of the rail vehicle, while the transmission unit is arranged axially on the axle without spring suspension. The shafts 2 , 3 of a drive unit or transmission unit (not shown here) to be connected to each other can thus be axially, radially and / or angularly offset / offset from one another.

[0030] In order to compensate axial, radial and / or angular offsets between the two shafts 2 , 3 , the compensating clutch 4 comprises a first and a second compensating unit 5 , 6 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com