A kind of integral connector end structure and its preparation method

A connector and integral technology, which is applied in the field of integral connector terminal structure and its preparation, can solve the problems of inability to proceed, product surface treatment process, breakage and falling off, etc., so as to save material costs, improve production efficiency, and produce consumables. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

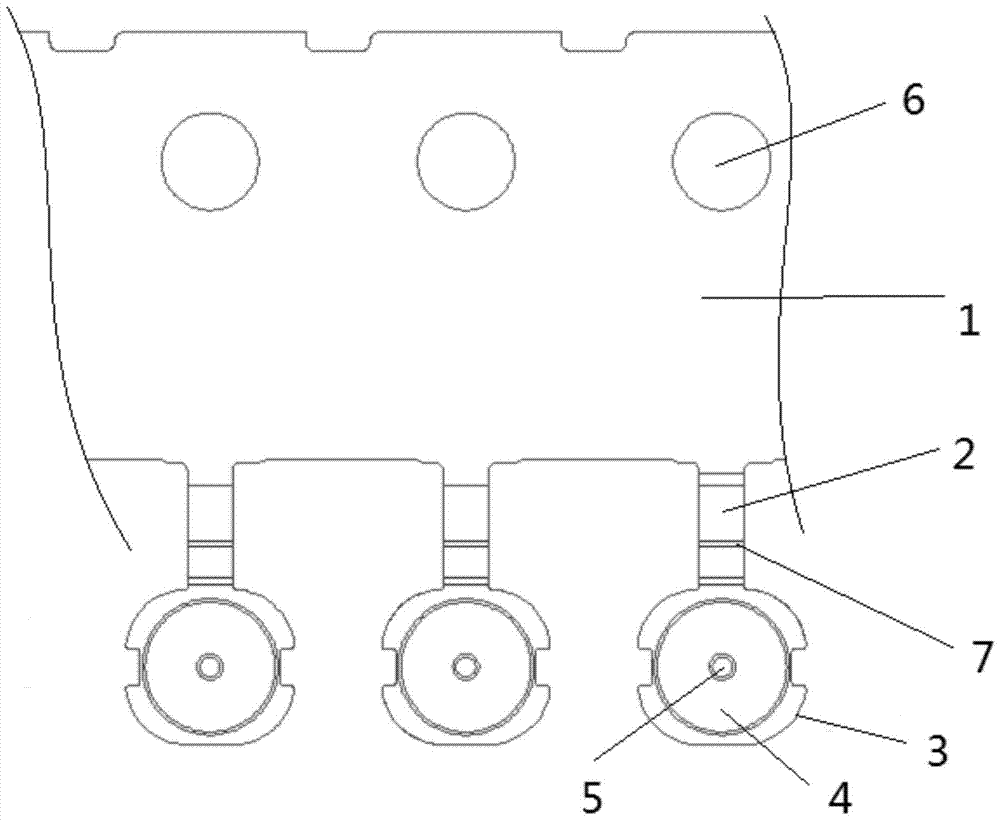

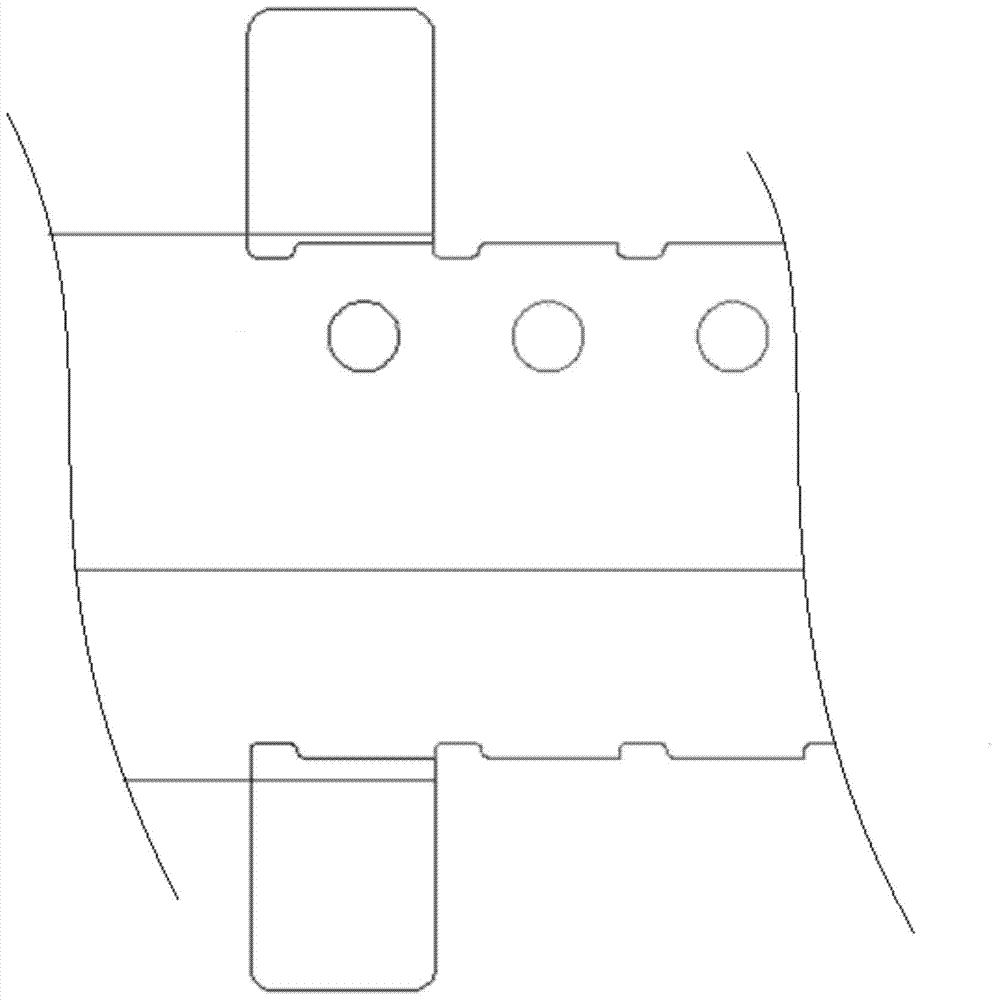

[0034] refer to Figures 1 to 4 As shown, an integral connector terminal structure includes a material strip 1 and a number of connecting arms 2 uniformly arranged at one end of the material strip, and one end of the connecting arm is also connected to the terminal 3, and the material strip, the connecting arm and the terminal are integrally formed A cylindrical structure 4 is provided in the middle of the surface of the end, and a truncated circular structure 5 is provided in the middle of the bottom surface of the terminal, and the terminal, the cylindrical structure and the truncated circular structure are integrally formed. The thickness of the strip is 0.15-0.5mm, the width of the connecting arm is 0.7mm, and the thickness of the connecting arm is consistent with the thickness of the end, which is 0.15mm. Here, the thickness of the material strip is greater than or equal to the thickness of the connecting arm, which ensures the reliability of the connection and the stabil...

Embodiment 2

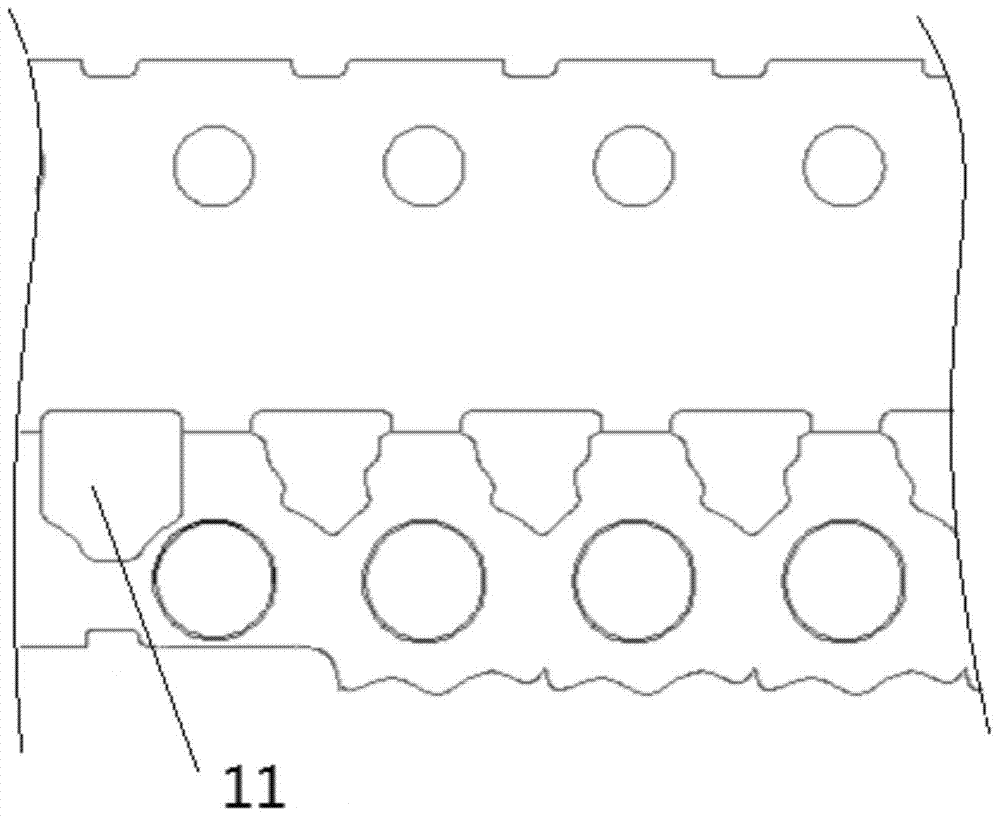

[0044] refer to Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the strip part in the step 1 is milled by a milling machine, and an interposition part 10 is reserved on one side of the strip part to ensure the effect of milling and cutting, and can be directly processed on the flat plate. Processing and use can reduce the cost input of using L-shaped structure plates. When pre-cutting the shape of the pre-molding material, the reserved clamping part will be cut off together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com