Concrete removal machine in steel pipe

A technology of concrete and cleaning machine, which is applied in the field of concrete equipment, can solve problems such as steel pipe blockage, and achieve the effects of reasonable structure, low power consumption and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

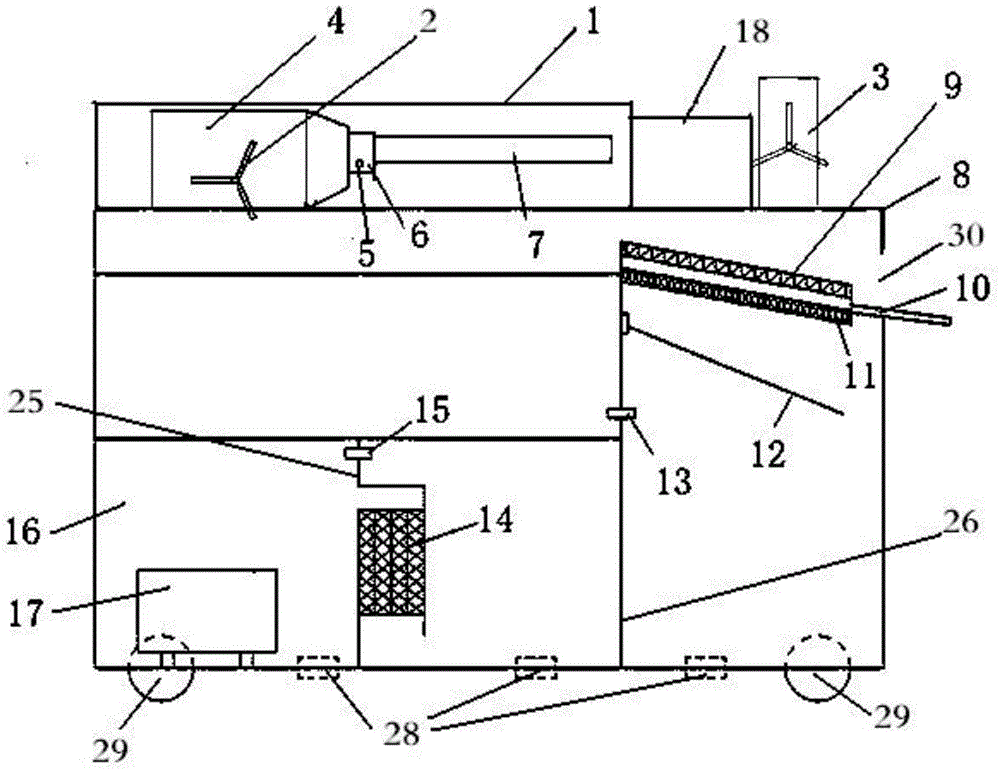

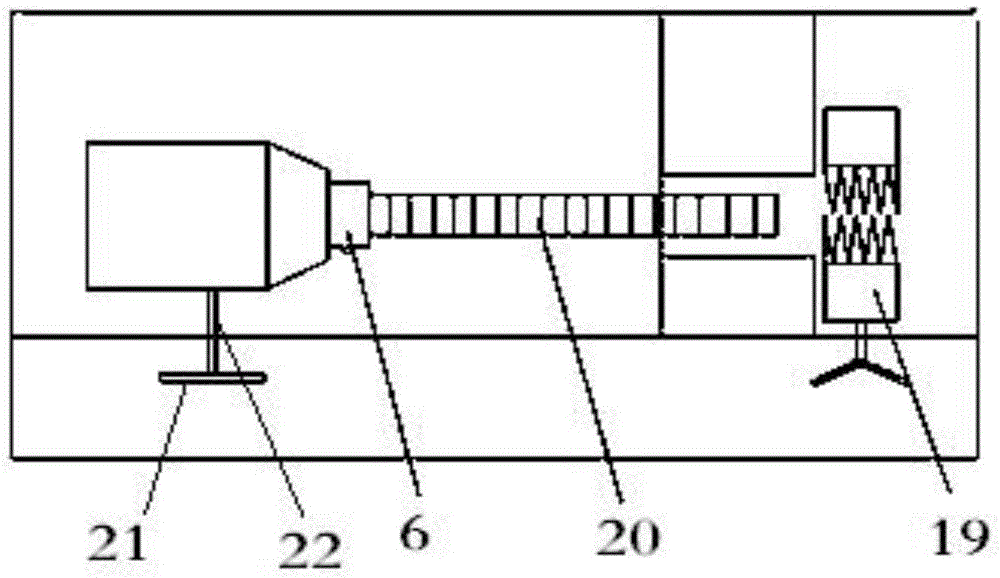

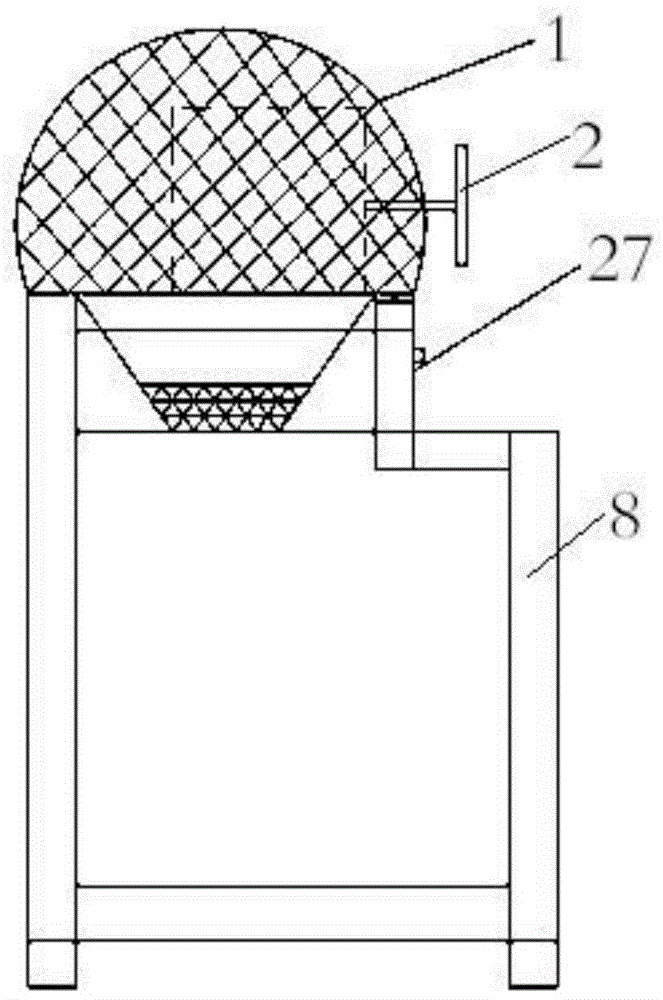

[0013] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises the body 8 that is installed on the frame, the water pump box 16 that is installed on the body, the filter box 23 and the settling box 24 that are next to each other, the belt protective cover that is installed in the water pump box 16 and the filter box 23 tops The drive transmission assembly 4 and the water drilling device of 1, the fixture device 3 for clamping the steel pipe installed above the sedimentation tank, the diversion baffle 18 arranged between the water drilling device and the fixture device, the diversion baffle and the The material-water separation net 9 under the fixture and the filter screen 11 located below the material-water separation net are connected to the guide groove 10 at the end of the filter screen to export the concrete fragments out of the settling tank, and are installed in the control box 27 outside the body. An anti-shock plate 12 is arranged below the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com