Paper-making method reconstituted tobacco wastewater deep treatment recycle system and technology

A technology of reconstituted tobacco leaves and advanced treatment, which is applied in the fields of flotation water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

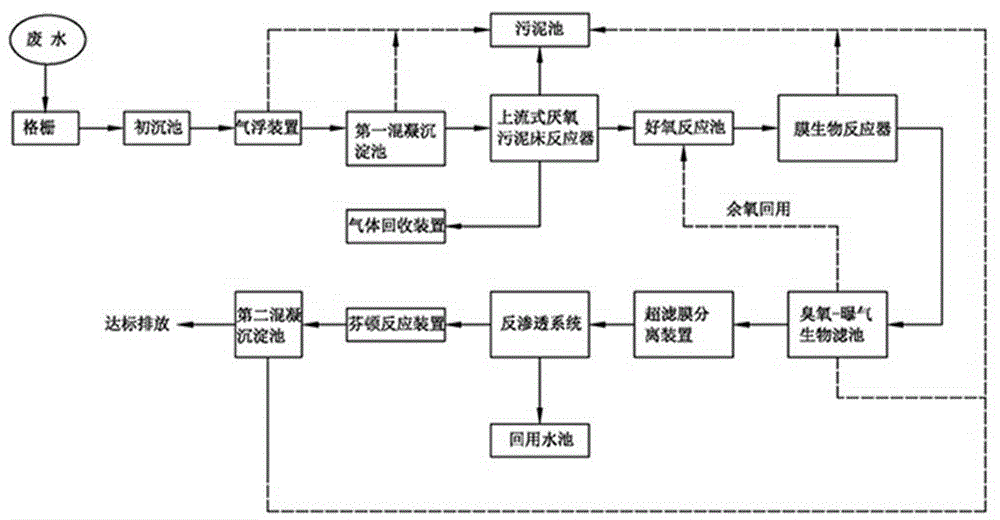

[0017] Such as figure 1 As shown, a system for advanced treatment and reuse of reconstituted tobacco waste water from papermaking method, including successively connected grids, primary sedimentation tanks, air flotation devices, first coagulation sedimentation tanks, and upflow anaerobic sludge bed reactor (UASB) , aerobic reaction tank, membrane bioreactor (MBR), ozone-aerated biological filter, ultrafiltration membrane separation device, reverse osmosis system; the water outlet of the reverse osmosis system is connected to the reuse pool, and the concentrated water outlet is connected to Fenton Reaction device, second coagulation sedimentation tank; also includes a sludge tank, the air flotation device, the first coagulation sedimentation tank, upflow anaerobic sludge bed reactor, membrane bioreactor, ozone-aeration The sludge outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com