Forming and shaping integrated production device for mute bearing retainer

A silent bearing and production device technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of silent bearing holder displacement, easy displacement, stamping needle deformation, etc., to ensure accuracy and avoid The effect of shifting and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

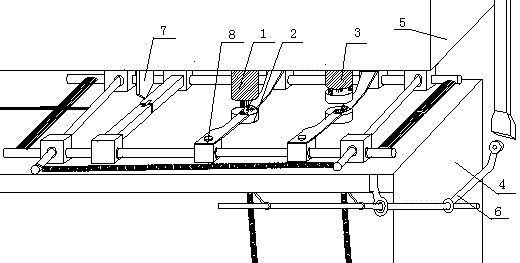

[0034] A forming and shaping integrated production device for a silent bearing retainer, including a discharge assembly 7, a shifting assembly 8, a forming and shaping integrated mold, and a punching mold 3, such as figure 1 .

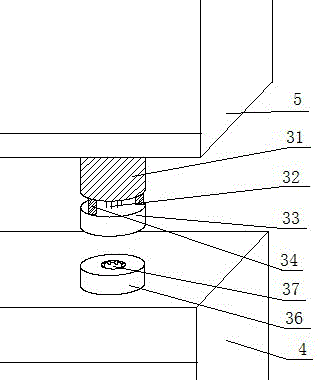

[0035] The discharge assembly 7 includes a discharge hydraulic cylinder, a retaining plate 72 and a vertebral plate 71, such as Figure 7 , the discharge hydraulic cylinder is set on the machine tool, the retaining plate 72 is connected to the piston rod of the discharge hydraulic cylinder, the vertebra plate 71 is provided with a line hole 73 for bolts to pass through, and the vertebra plate 71 is connected by bolts and nuts on the retaining plate. On the plate 72, the left longitudinal guide block 89 is connected with the left block 816, the right longitudinal guide block 810 is connected with the right block 817, the ends of the left block 816 and the right block 817 are respectively provided with bar-shaped grooves, and the vertebral plate 71 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com