Patents

Literature

30results about How to "Generate less waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

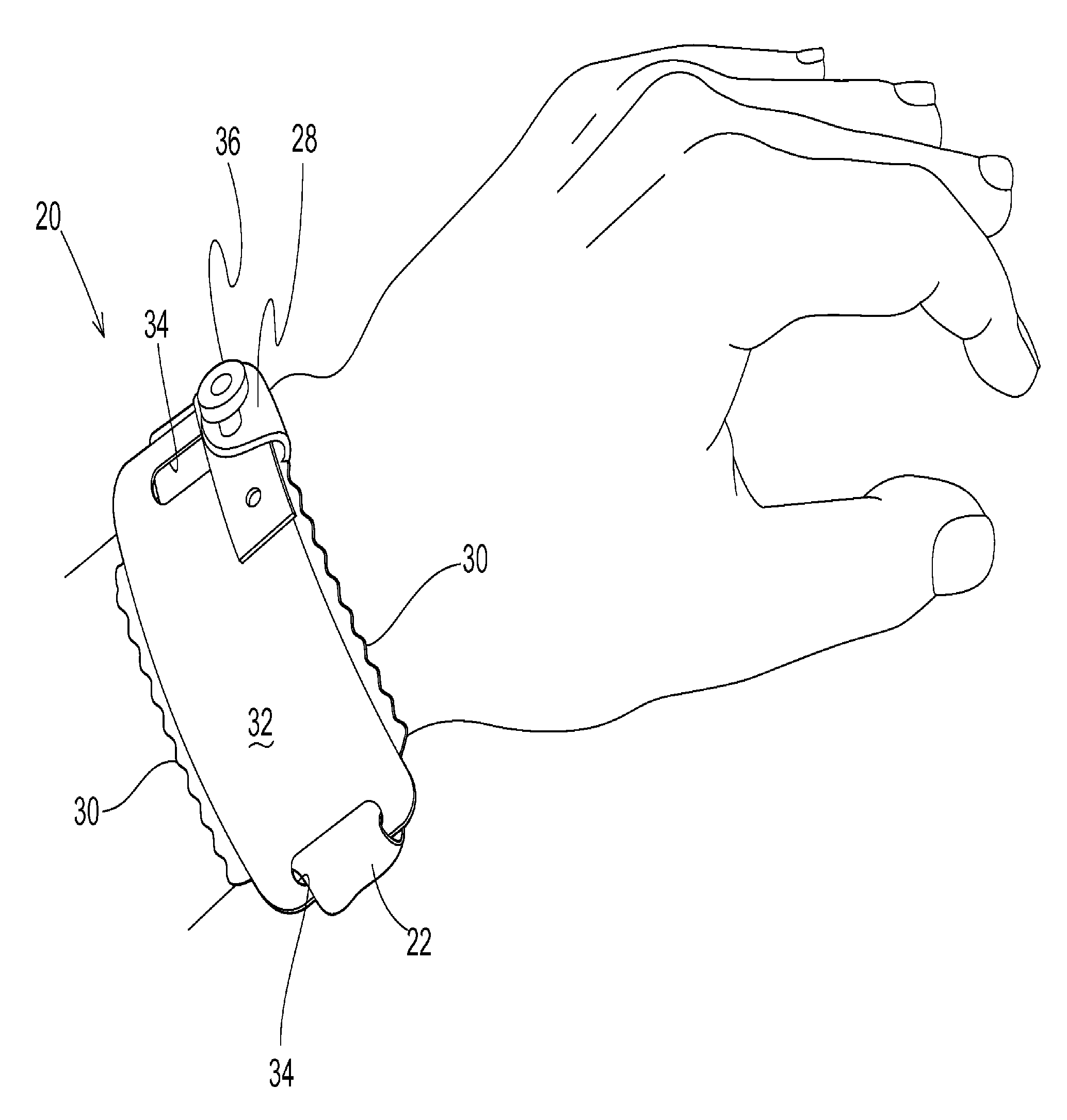

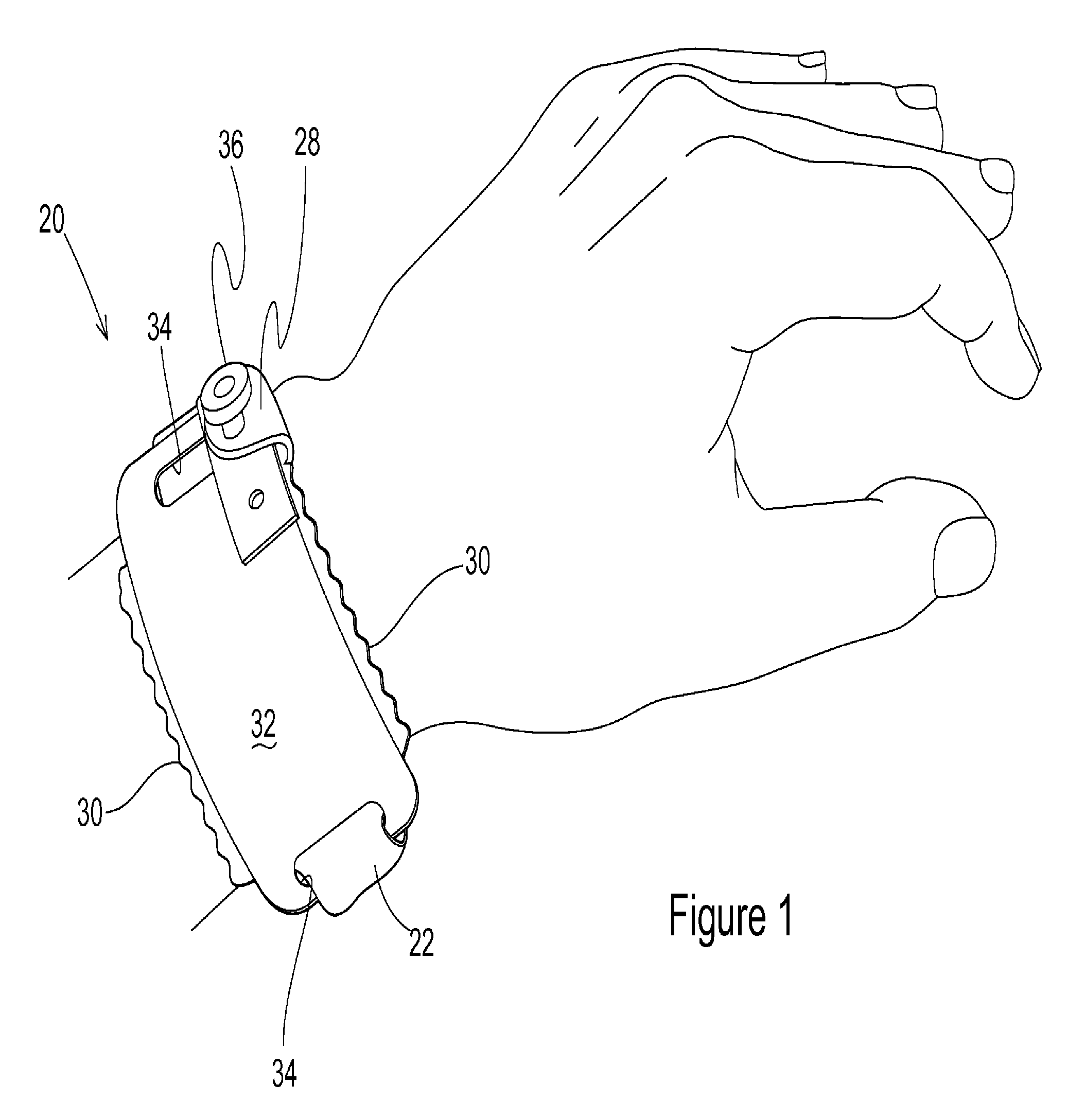

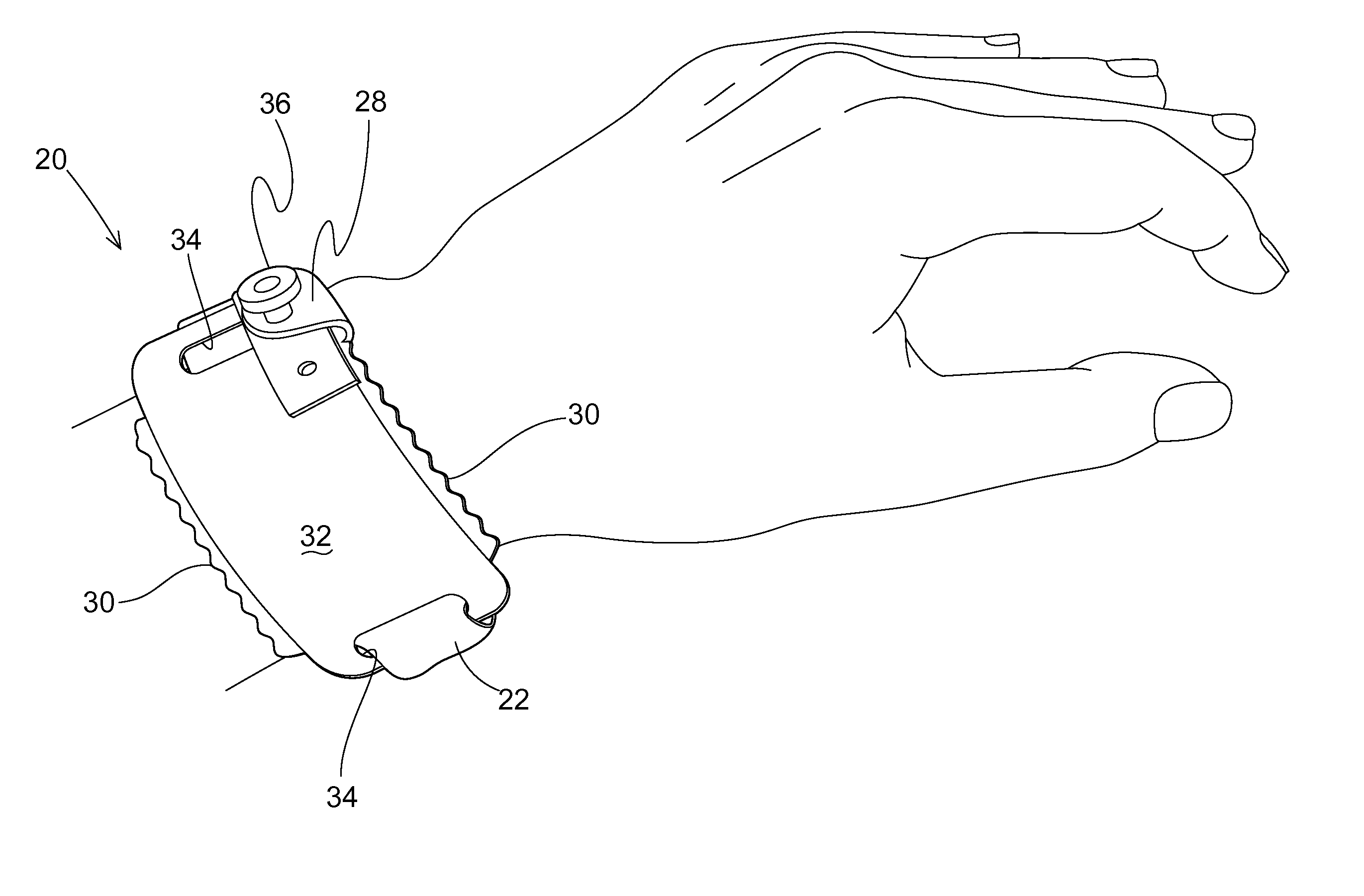

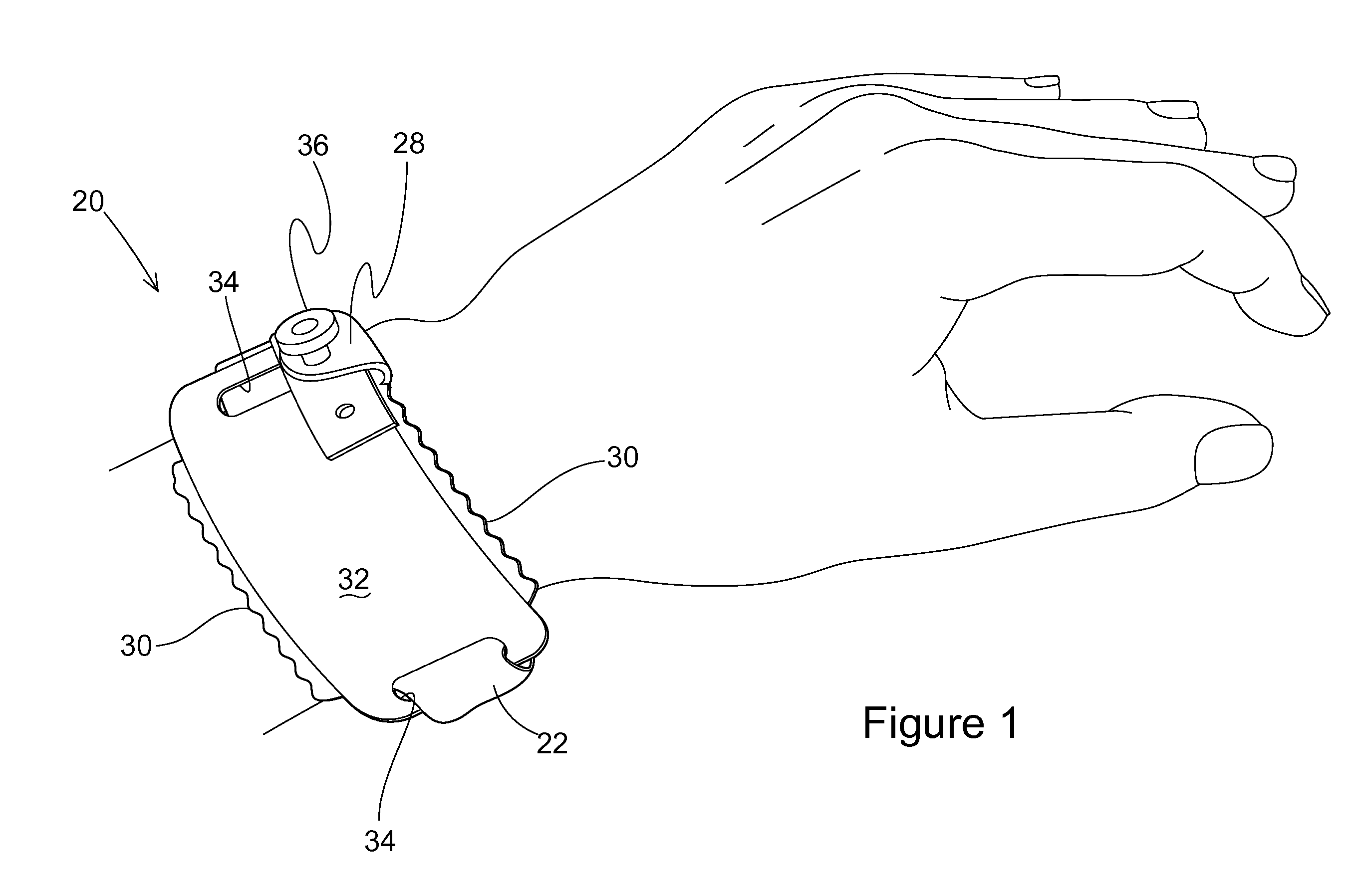

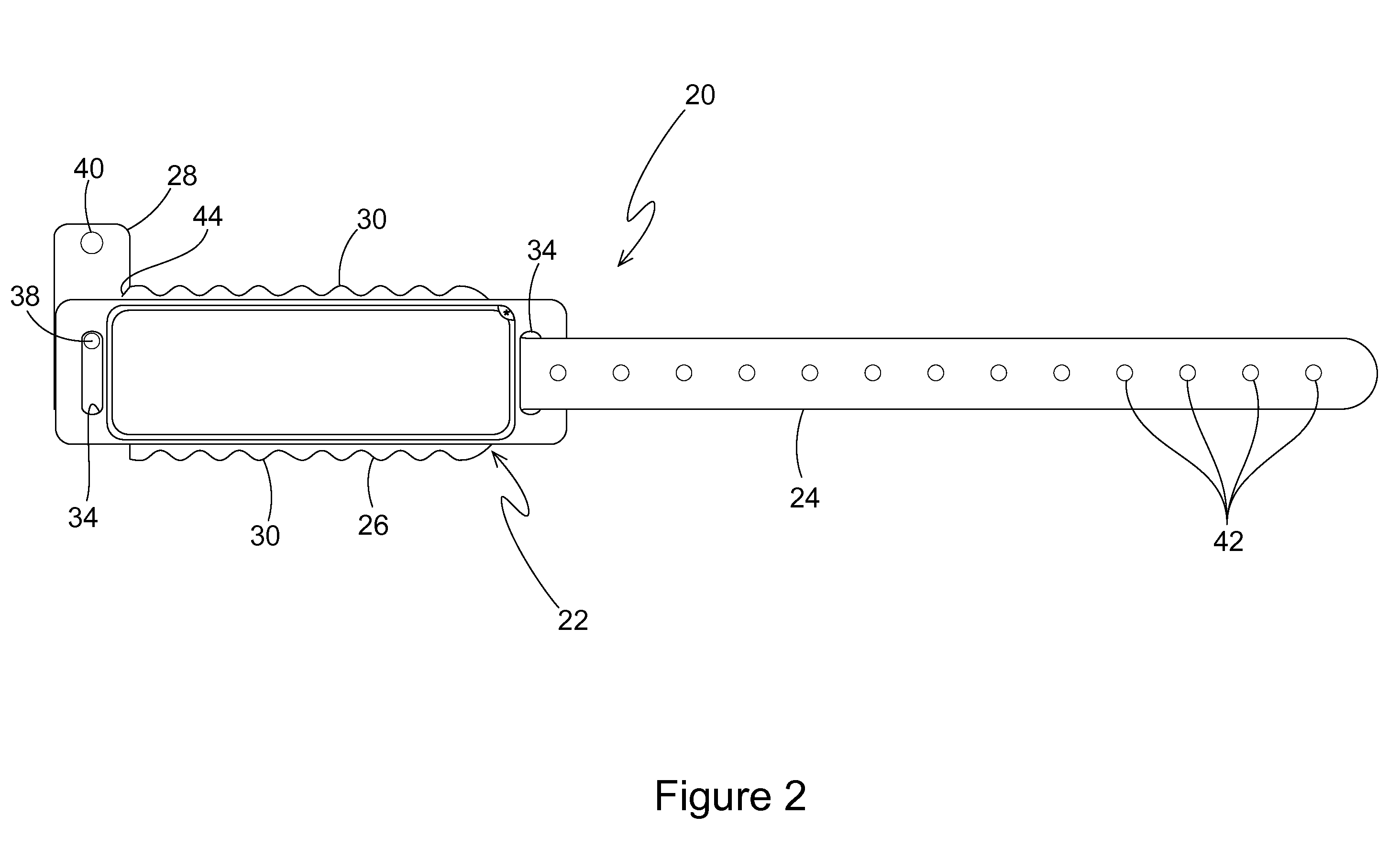

Business Form With Wristband Carriers

ActiveUS20090282717A1Great commercial successSimple designStampsPerson identificationFace sheetBusiness forms

Owner:ZEBRA TECH CORP

Preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid

ActiveCN104370755ANon-hazardousImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationSolventHydrolysis

The present invention discloses a preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid. The optical activity active 3-amino butanol preparation method comprises: in a solvent, under effects of a hydroboration reduction agent and a Lewis acid, carrying out a reduction reaction on a compound represented by a formlu 65 to produce a compound represented by a formlu 14. The optical activity active 3-amino butyric acid preparation method comprises: carrying out a hydrolysis reaction on a compound represented by a formlu 64 to produce a compound represented by a formlu 65. According to the present invention, the preparation method has characteristics of cheap and easily-available raw materials, simple operation, short process route, no hazard of raw materials, high yield, little waste production, environment protection, high raw material conversion rate, high product chemical purity and high product optical purity, and the industrialization is easily achieved. The formulas 64, 65 and 14 are defined in the instruction.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

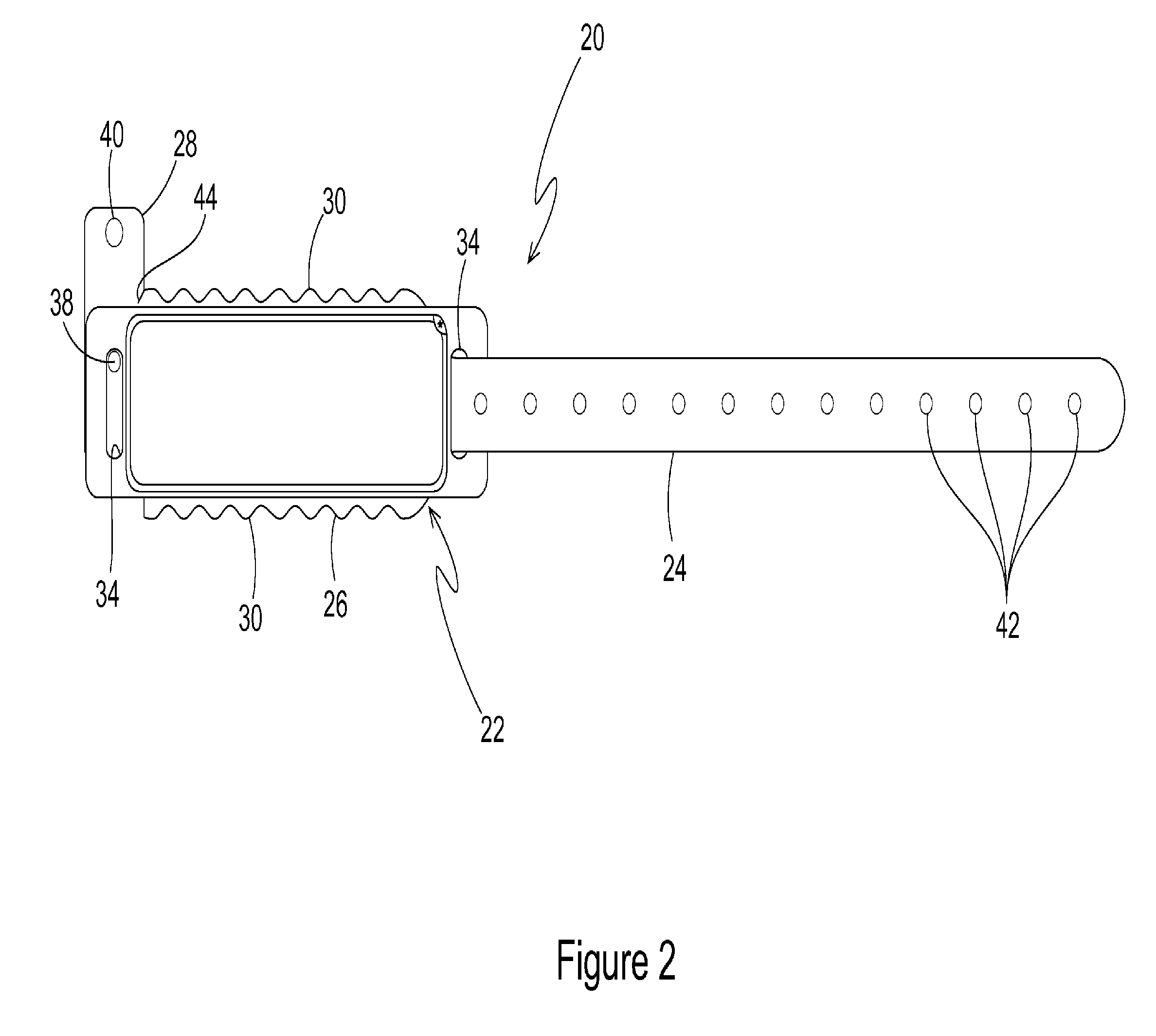

Wristband With Snap Closure And Patient ID Label

InactiveUS20080098635A1Simple designEase of use and stabilityStampsPerson identificationElectrical and Electronics engineering

A wristband is assembled from a flexible preferably vinyl carrier and a preferably laminated ID label, the carrier having a panel portion and a strap portion with a snap closure located in a toe extension at the end of the carrier adjacent the panel. The strap has a series of holes, one of which is captured within the snap closure to attach the wristband to the wearer's limb. The laminated ID label has a pair of opposing slots, one of which slips over the strap to abut the panel and the other of which is captured by the snap closure to attach the label to the carrier. The panel portion has a relieved edge formed along its opposing sides which increases the comfort of the wristband as it is worn.

Owner:LASERBAND LLC

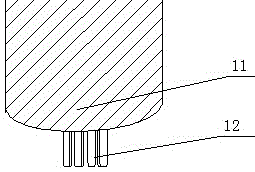

A new type of solid welding wire processing and manufacturing method

ActiveCN103286481BHigh strengthImprove plasticityWelding/cutting media/materialsSoldering mediaNonferrous metalMegasonic cleaning

The invention relates to the field of welding material manufacturing, in particular to a manufacturing method of novel solid welding wires. The method starting from wire rod machining sequentially includes: forging, annealing, continuously wire drawing, scraping, and ultrasonic wave cleaning to obtain the solid welding wires which are bright and fine-grain. The solid welding wires include various non-ferrous metal and non-ferrous metal alloy welding wires. The manufactured solid welding wires have fine and even equiaxed grains on the transverse end faces and the longitudinal end faces, product strength and plasticity are increased evidently compared with other manufacturing methods, and excellent mechanical property is achieved. In addition, the manufacturing method is simple in process, low in waste material, high in yield and the like.

Owner:抚顺东工冶金材料技术有限公司

Preparation method of hydroxy-terminated perfluoropolyether compound

ActiveCN102660012AEasy to separateHigh reaction yieldOrganic chemistryOrganic compound preparationActivated carbonPolymer science

The invention relates to a preparation method of a hydroxy-terminated perfluoropolyether compound. Perfluoropolyether carboxylic acid or ester used as a raw material is subjected to reducing reaction to obtain the hydroxy-terminated perfluoropolyether compound, wherein hydrogen is used as the reducer of the reducing reaction, an activated carbon supported ruthenium or rhodium catalyst is used as the catalyst, and the reaction is carried out at 80-200 DEG C under the pressure of 10-50MPa. Compared with the prior art, the invention has the advantages of high reaction yield, simple after-treatment and fewer three wastes, and is simple to operate.

Owner:太仓中化环保化工有限公司 +2

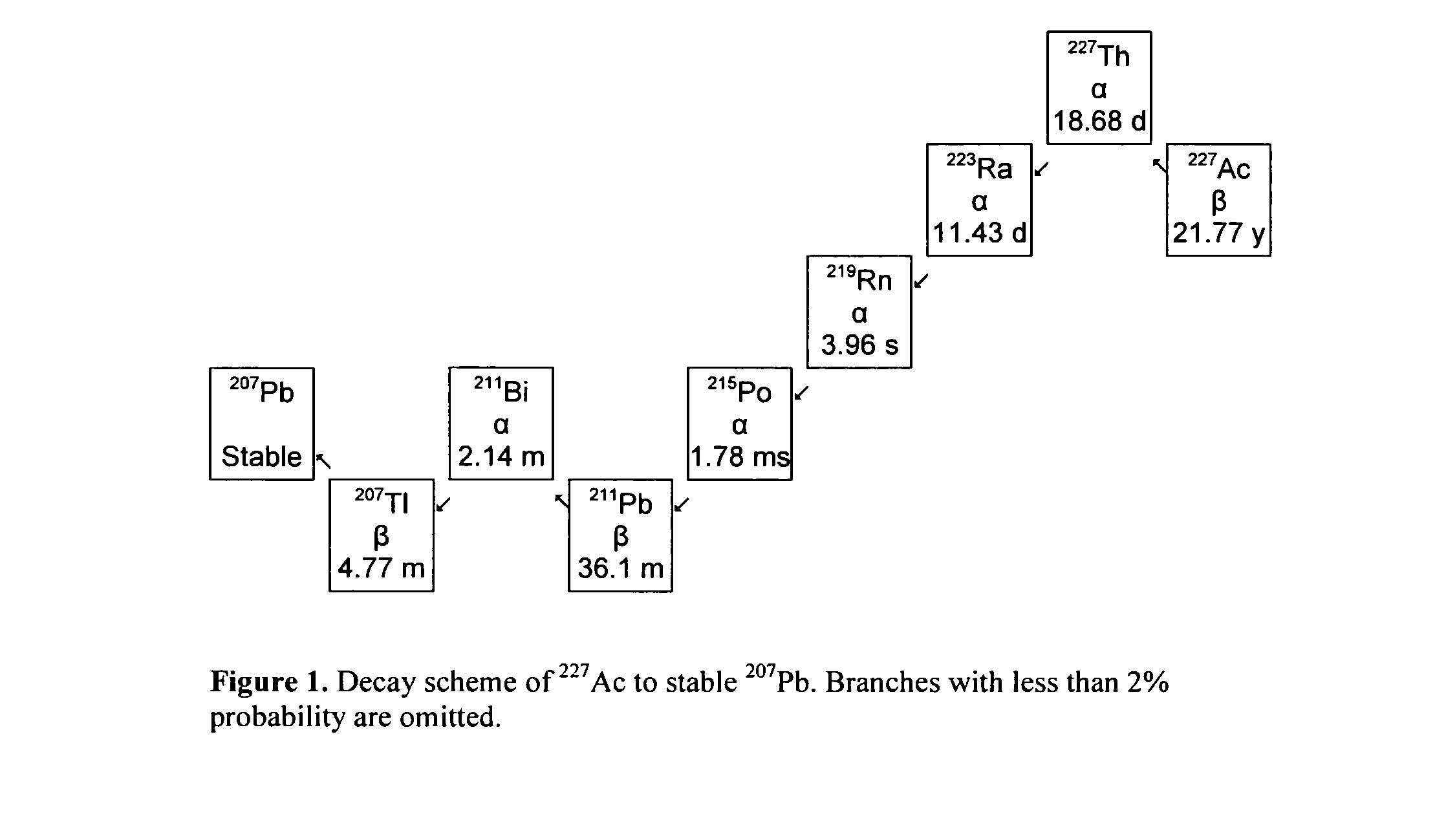

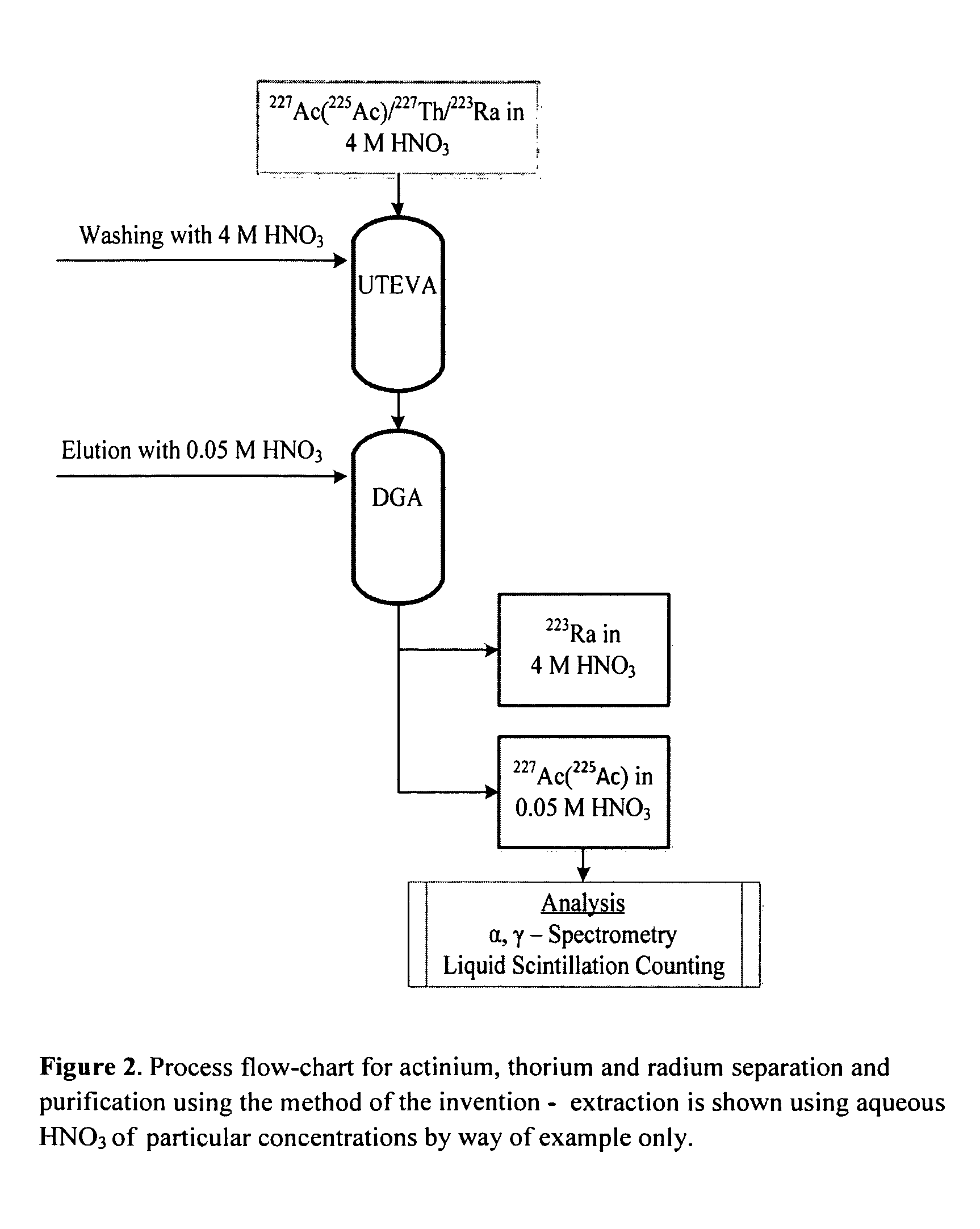

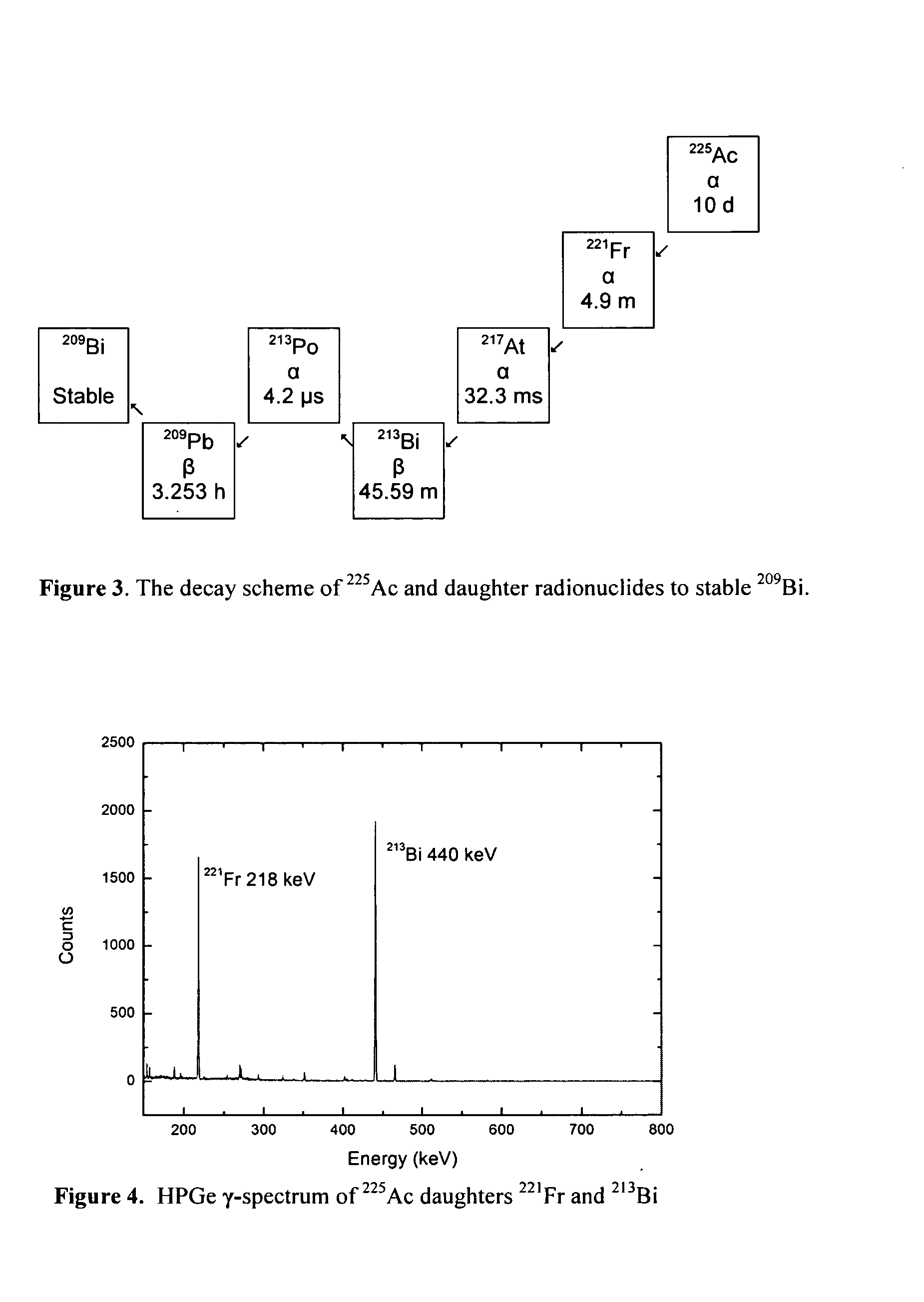

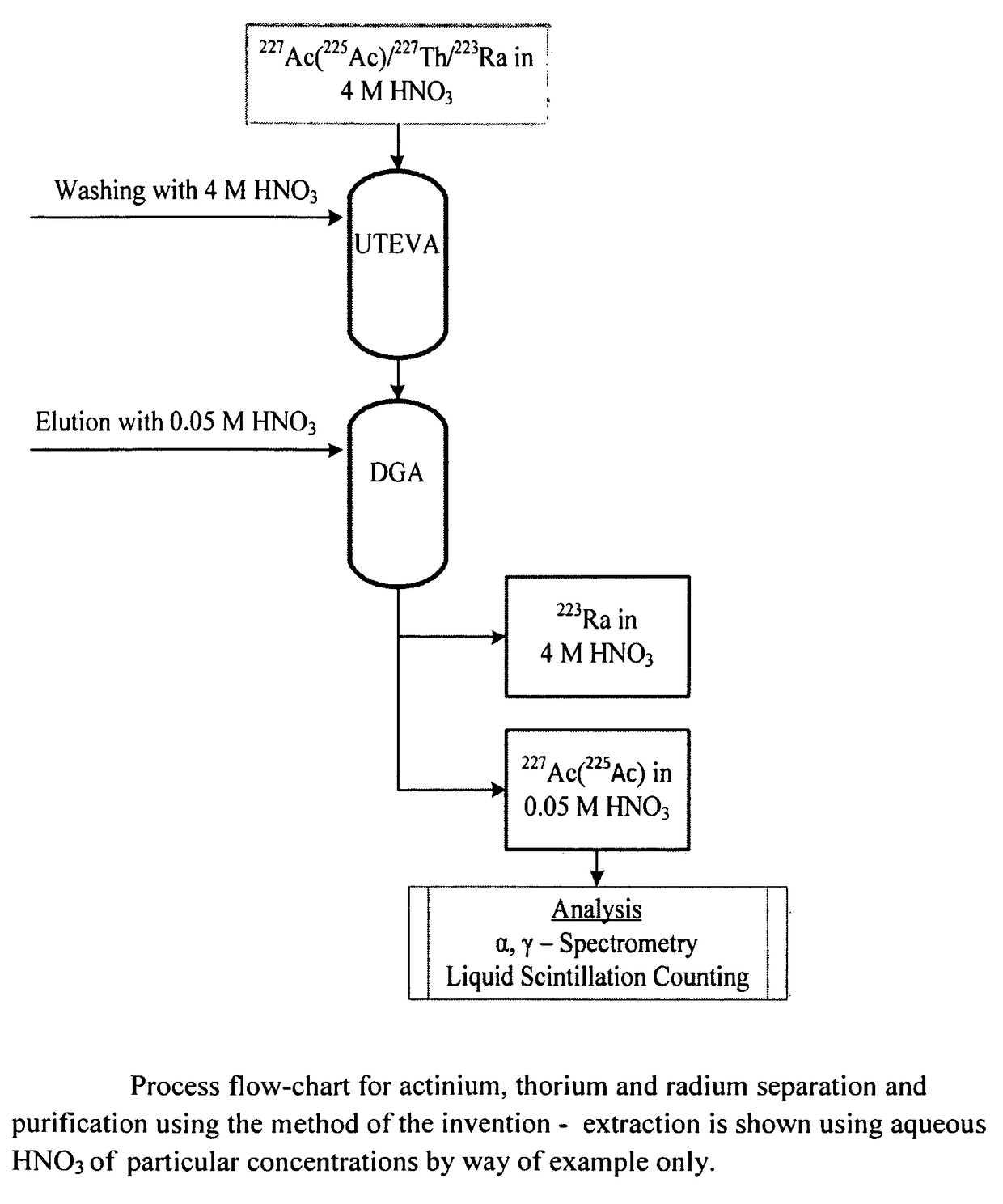

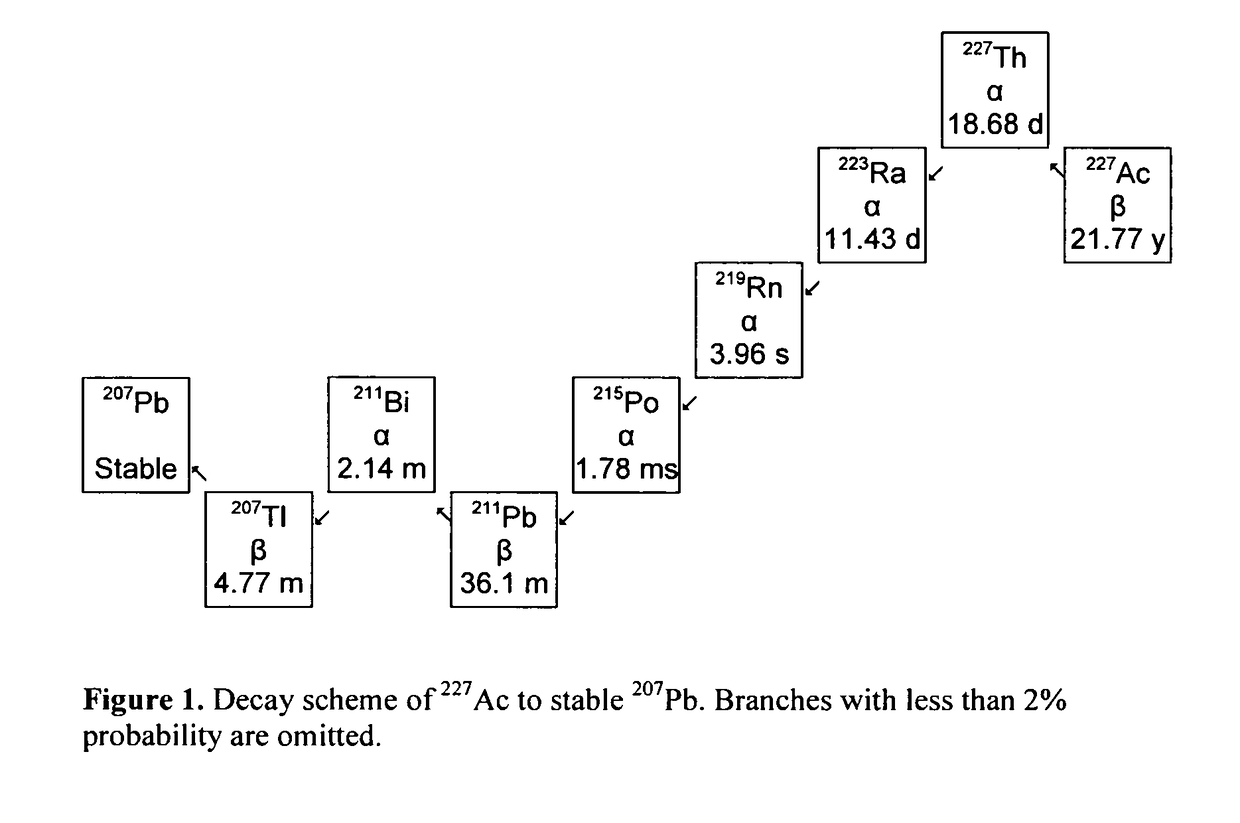

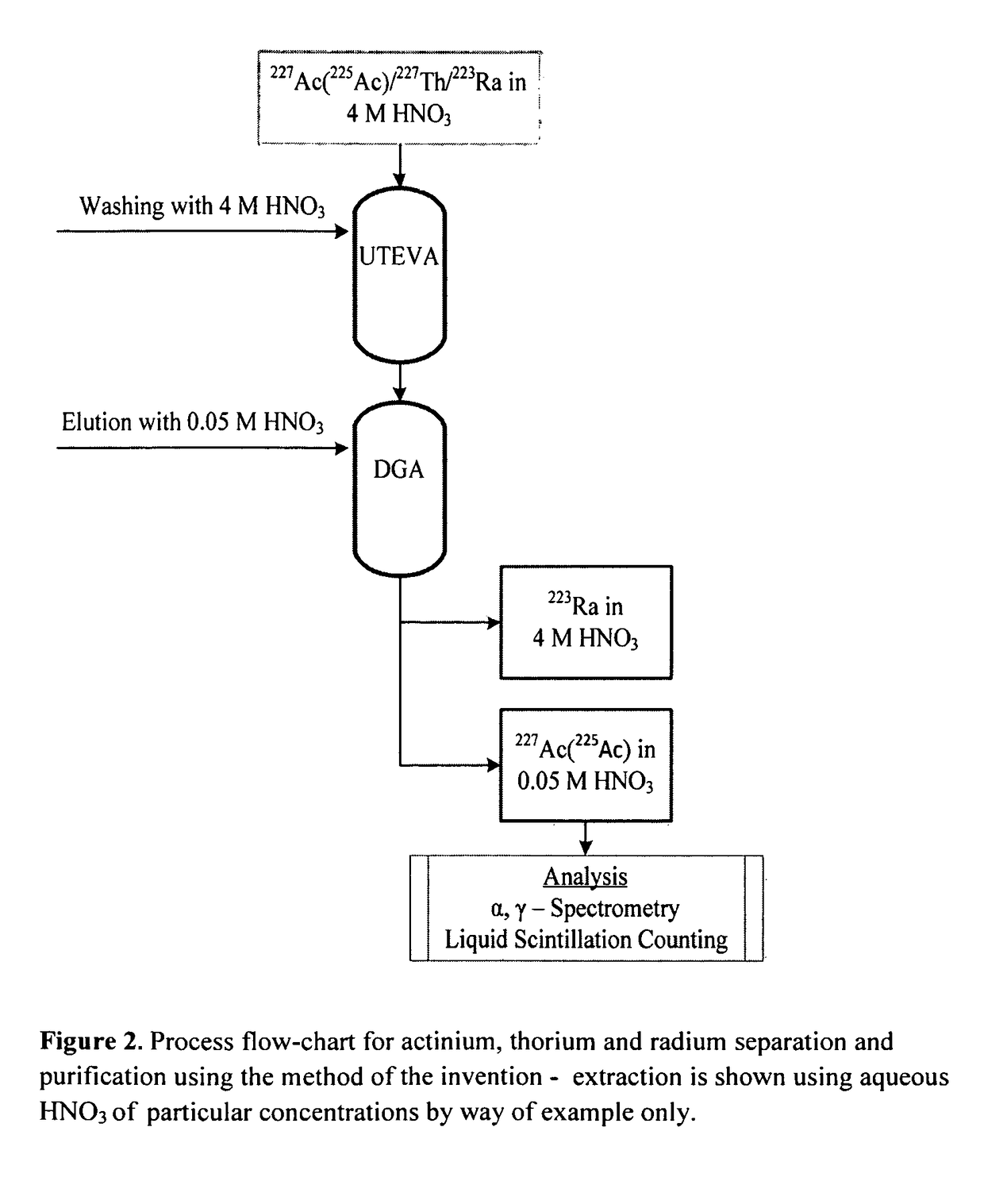

Method for the quantification of 227ac in 223ra compositions

ActiveUS20160209387A1Rapid quantitationFast and efficientSpecific isotope recoveryMaterial analysis using wave/particle radiationActiniumSolid phase extraction

A method for the quantification of 227Ac in a 223Ra composition comprising passing the composition through a first solid phase extraction column A, wherein said column comprises a thorium specific resin, passing the eluate of column A through a second solid phase extraction column B, wherein said column comprises an actinium specific resin and recovering the 227Ac absorbed onto the resin in column B and determining the amount thereof.

Owner:BAYER AS

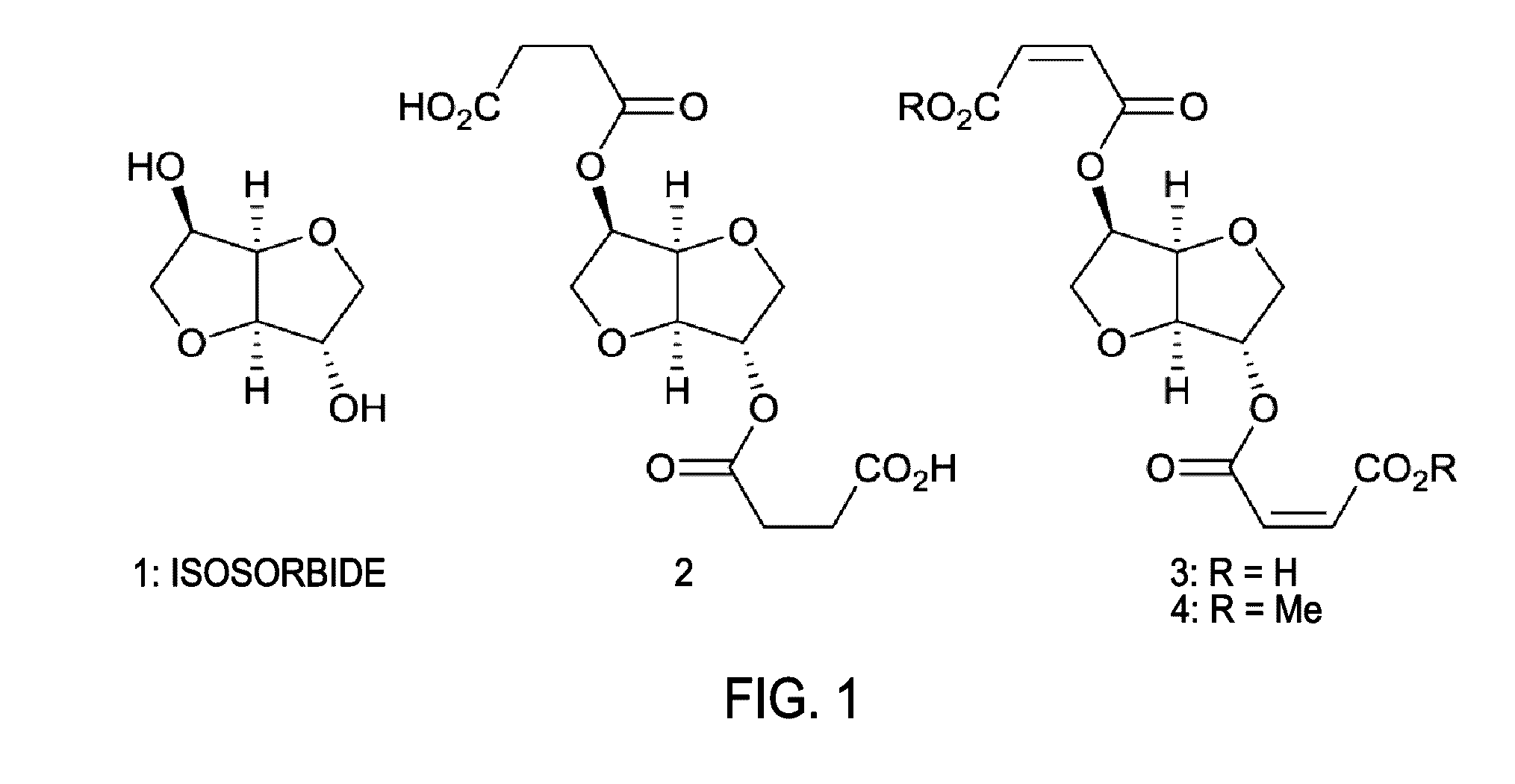

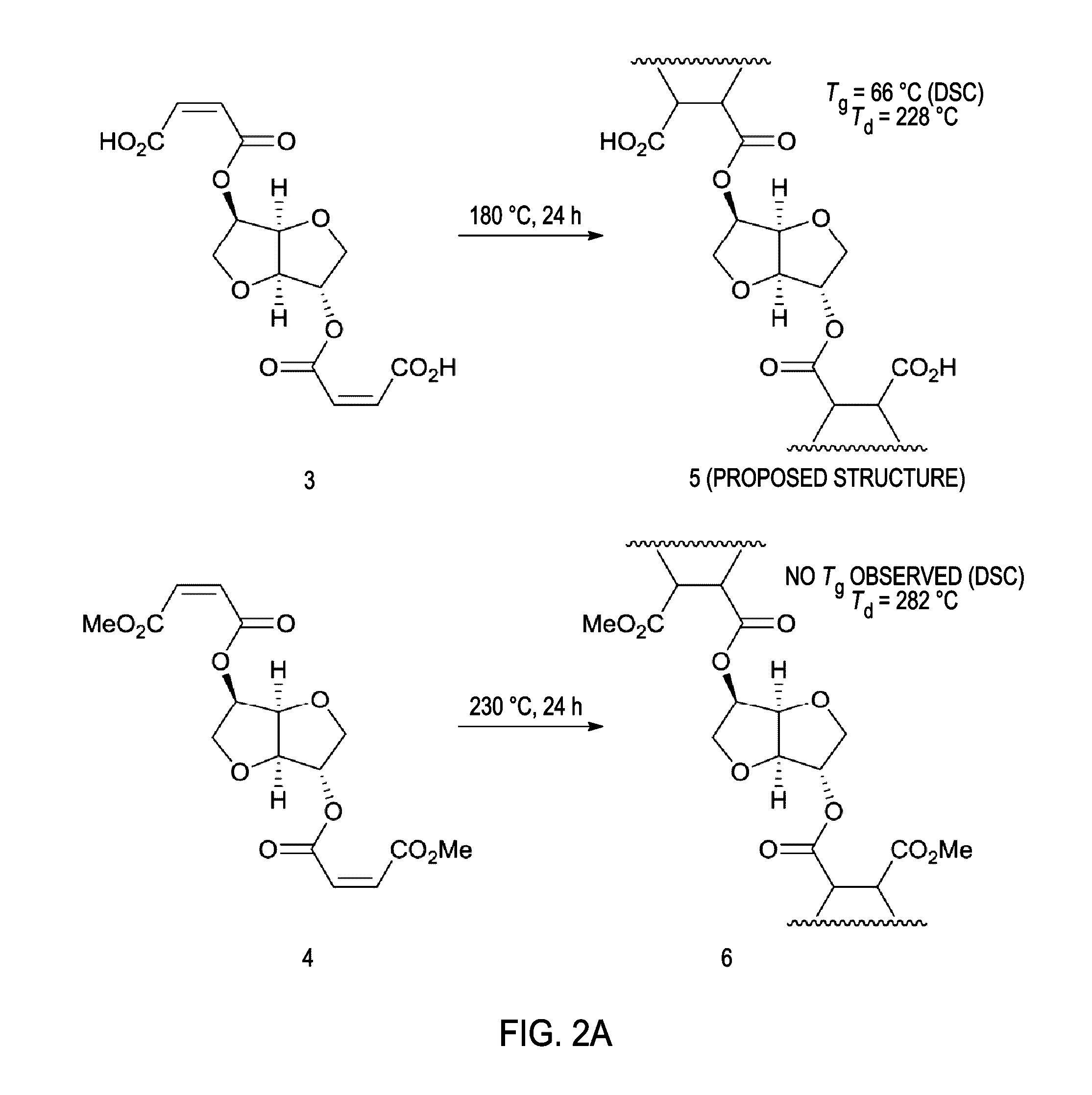

Polymers and methods of making the same

Various embodiments disclosed relate to polymers and methods of making the same. In various embodiments, the present invention provides a method of forming a polymer including subjecting a composition including a carboxylic acid having the structure (Rf—O)z1—Ra to conditions sufficient to form a polymer having the structure Reg—[O—Ra(O—Rb)z1-2—O—C(O)—R′(O—Rd)z2-1—C(O)]n—O—Ra(O—Rb)z1-2—O—Reg or a salt or ester thereof, wherein Ra, R′ Rb, Rd, Rf, Reg, z1, z2, and n are as defined herein. In various embodiments, the polymer is a tackifier, a viscosifier, or a combination thereof.

Owner:IOWA STATE UNIV RES FOUND

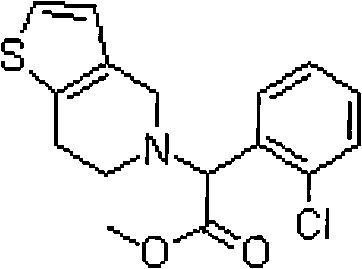

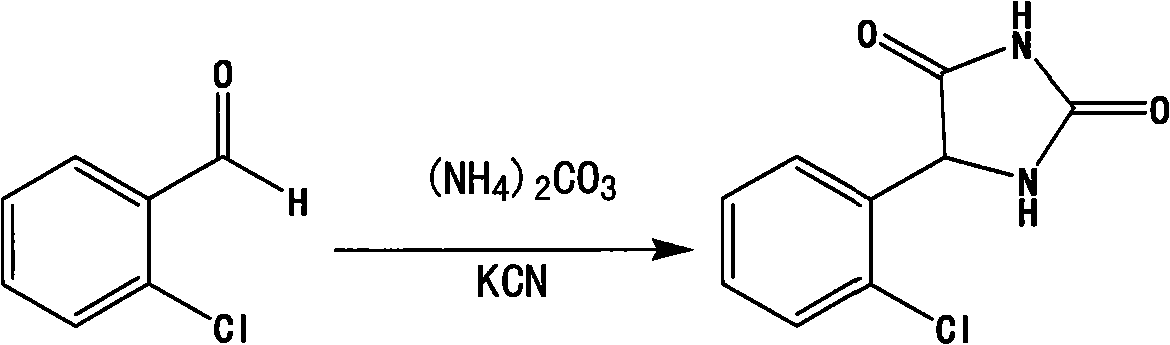

Preparation method of S-(+)-o-chlorobenzoyl glycine

InactiveCN101560533ALow costSimple processOrganic compound preparationAmino-carboxyl compound preparationGlycineOrganic solvent

The invention relates to a preparation method of S-(+)-o-chlorobenzoyl glycine, which comprises the following steps: firstly, o-chlorobenzaldehyde, potassium cyanide and ammonium carbonate are used as raw materials for synthesizing (plus or minus) o-chlorobenzoyl-hydantoin; and then agrobacterium is used as enzyme and the S-(+)-o-chlorobenzoyl-hydantoin is selectively hydrolyzed into S-(+)-o-chlorobenzoyl glycine, and R-(-)-o-chlorobenzoyl-hydantoin is self-racemized and hydrolyzed into S-(+)-o-chlorobenzoyl glycine. Compared with the traditional splitting method, no chiral compound is used in the production technique, chiral products are obtained directly through enzyme catalysis and splitting is not needed, therefore, the production technique has high yield, low cost and simplified technique; in addition, as the technology of enzyme catalysis is used, less organic solvent is used and less waste is produced in the whole production technical process, thus being beneficial to the environmental protection.

Owner:SUZHOU LIXIN PHARMA

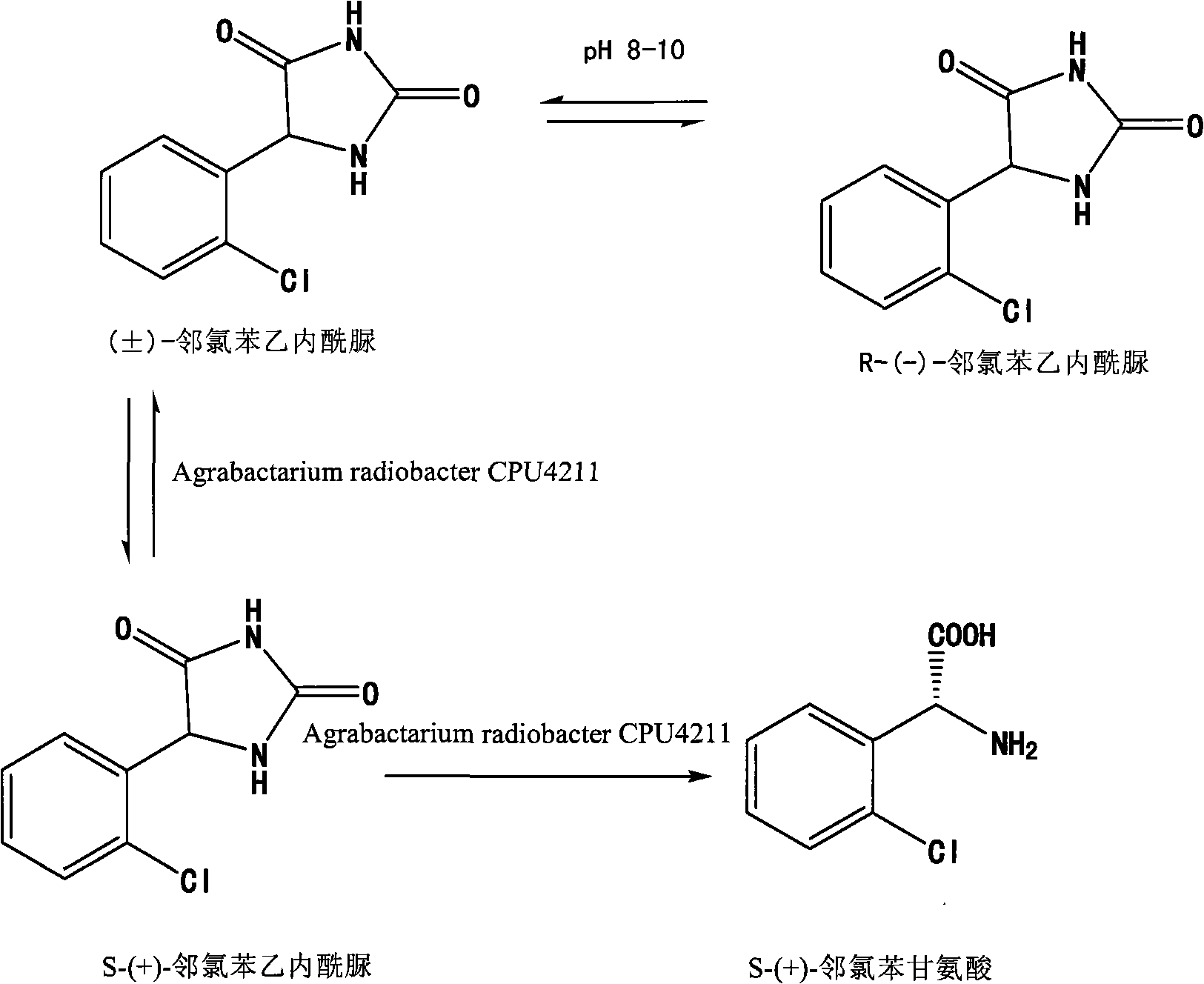

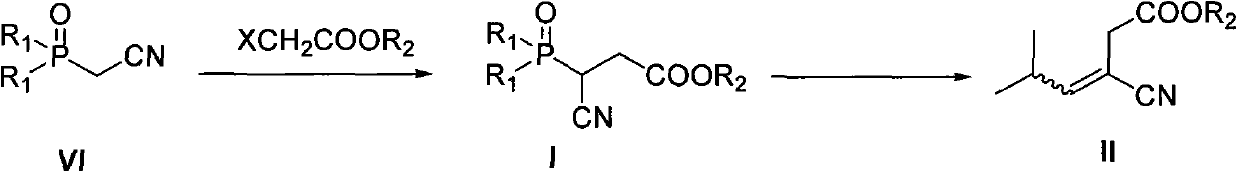

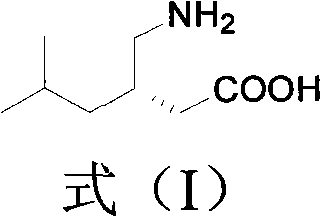

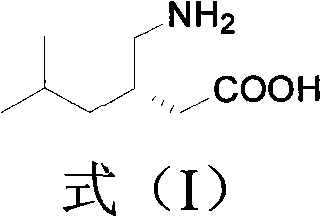

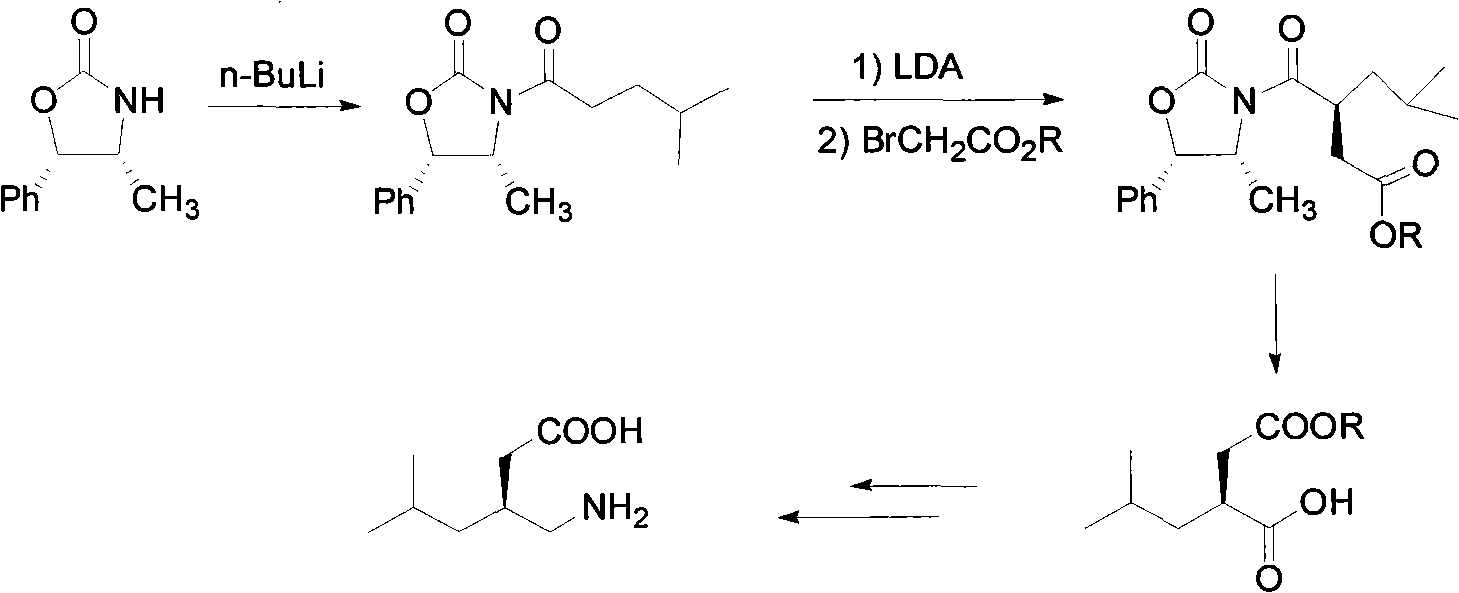

Preparation method of intermediate compound of pregabalin

ActiveCN102464594AImprove conversion rateHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationArylHydrogen

The invention discloses a preparation method for preparing an intermediate compound II of pregabalin. The preparation method of the intermediate compound II comprises the following steps of: (1) undergoing an SN2 substitution reaction on a compound VI and XCH2COOR2 to obtain a compound I; and (2) undergoing a Wittig-Hornor reaction on the compound I obtained in the step (1) and isobutylaldehyde, wherein R1 is alkoxyl with 1-6 carbon atoms or aryl with 6-10 carbon atoms; X is halogen; and R2 is alkyl with 1-6 carbon atoms. The invention further relates to a preparation method for preparing an intermediate compound V of pregabalin. The preparation method of the intermediate compound V comprises the following step of: undergoing an asymmetric hydrogenation reaction on the compound IV and hydrogen gas in a solvent under the action of [Rh((Sc,Rp)-Duanpos)(COD)]BF4, wherein M is H, alkyl with 1-6 carbon atoms or t-BuNH<3+>.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

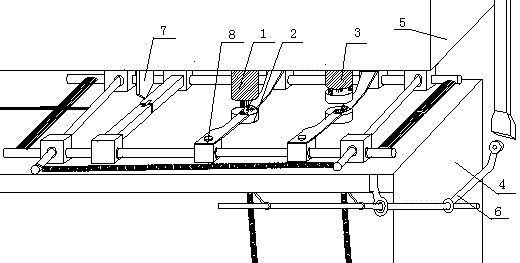

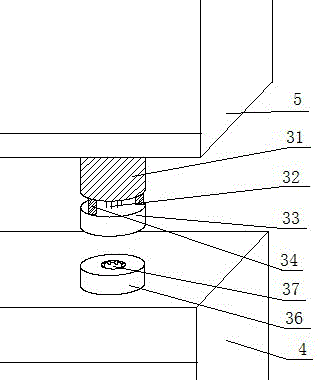

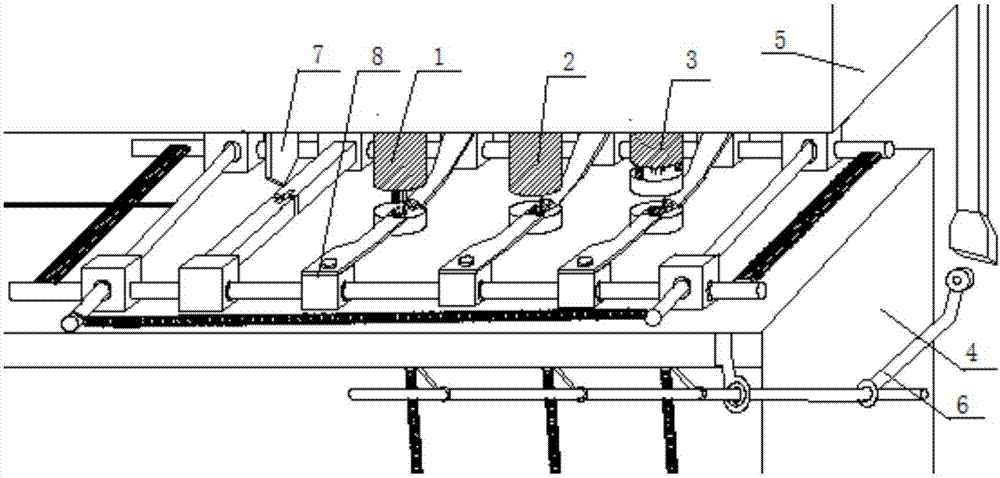

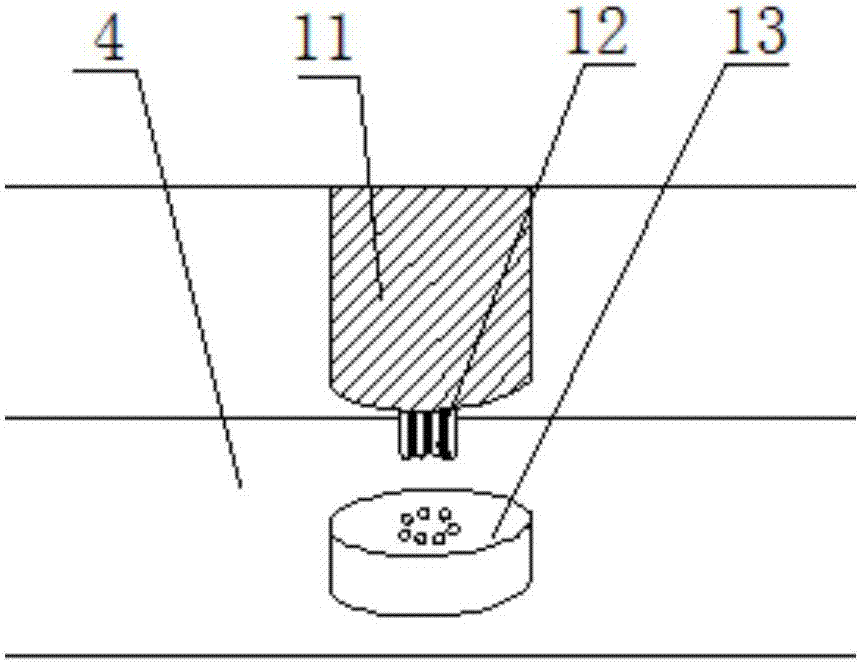

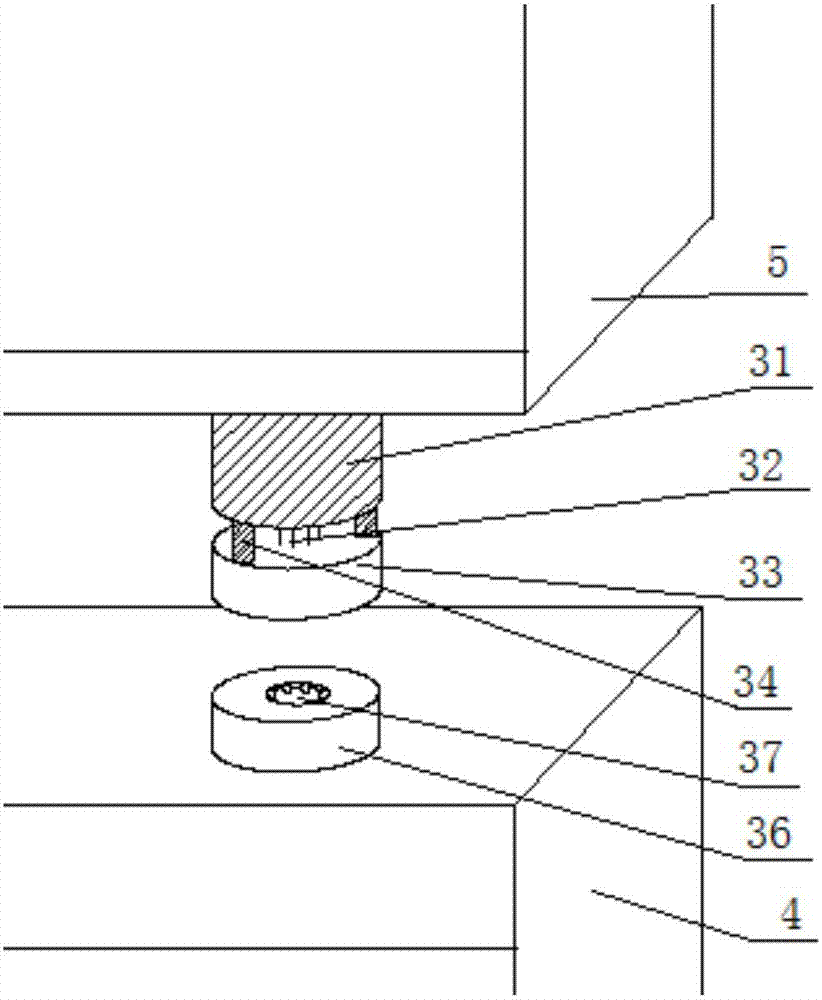

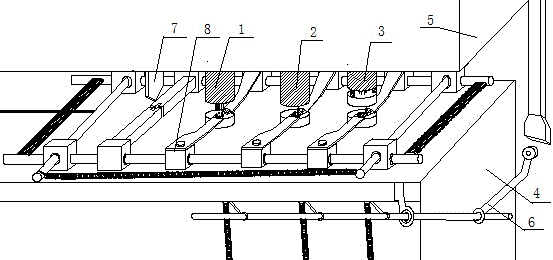

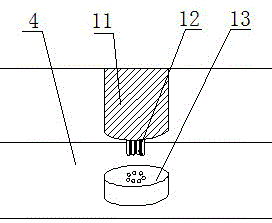

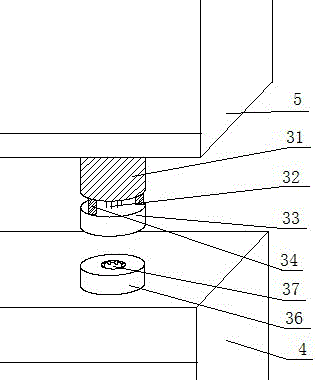

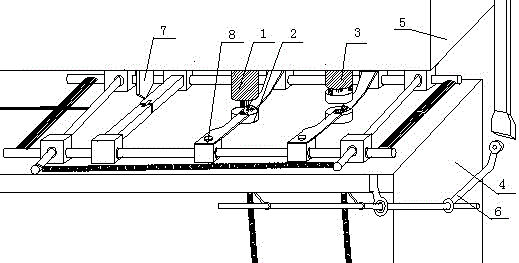

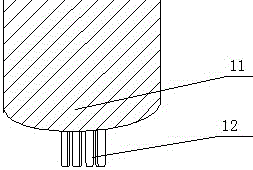

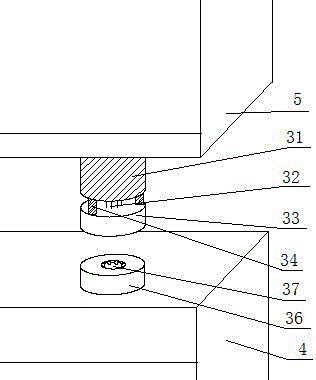

Forming and shaping integrated production device for mute bearing retainer

ActiveCN105107937ARealize automatic shiftAvoid displacementShaping toolsPerforating toolsHydraulic cylinderPunching

The invention provides a forming and shaping integrated production device for a mute bearing retainer. The forming and shaping integrated production device for the mute bearing retainer comprises a feeding assembly, a movement assembly, a forming and shaping integrated die and a punching die. The feeding assembly comprises a feeding hydraulic cylinder, a position fixing plate and a pushing plate. The movement assembly comprises a first transverse guide rod, a second transverse guide rod, a left longitudinal guide rod, a right longitudinal guide rod, a transverse reset spring and a longitudinal reset spring. The feeding assembly, the forming and shaping integrated die and the punching die are sequentially arranged between the left longitudinal guide rod and the right longitudinal guide rod. The forming and shaping integrated die comprises an integrated upper die and an integrated lower die. The punching die comprises an upper punching die body and a lower punching die body. The forming and shaping integrated production device for the mute bearing retainer is reasonable in structural design, automatic movement can be achieved when workpieces are machined, the machining accuracy is high, a few waste materials are generated, and using for production is facilitated.

Owner:江苏盐新汽车产业投资发展集团有限公司

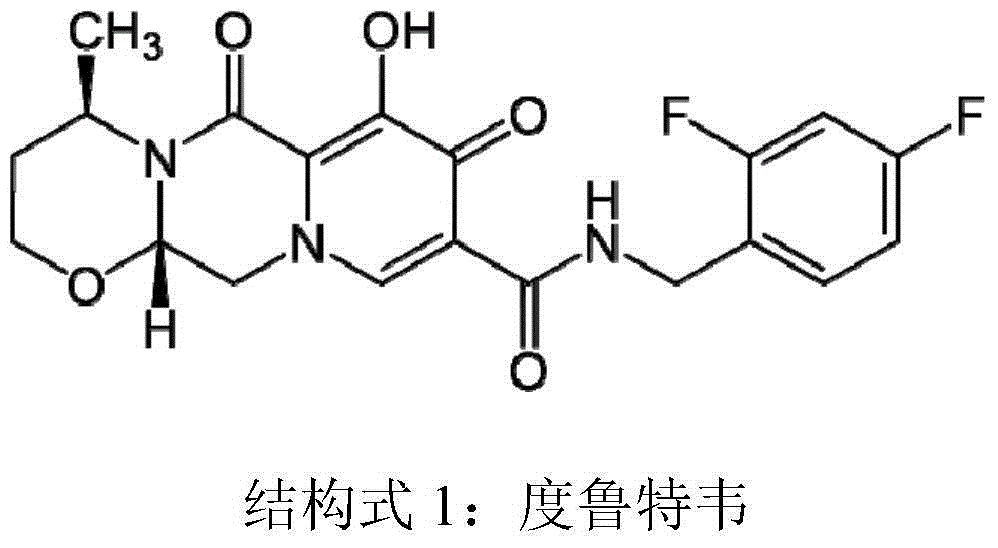

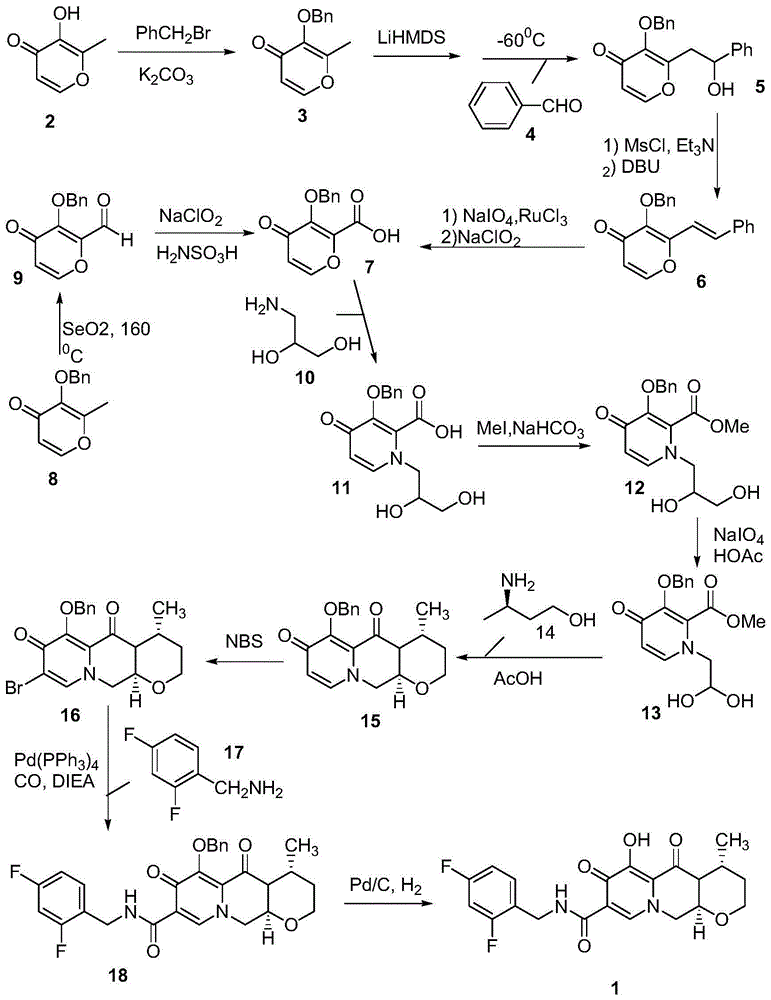

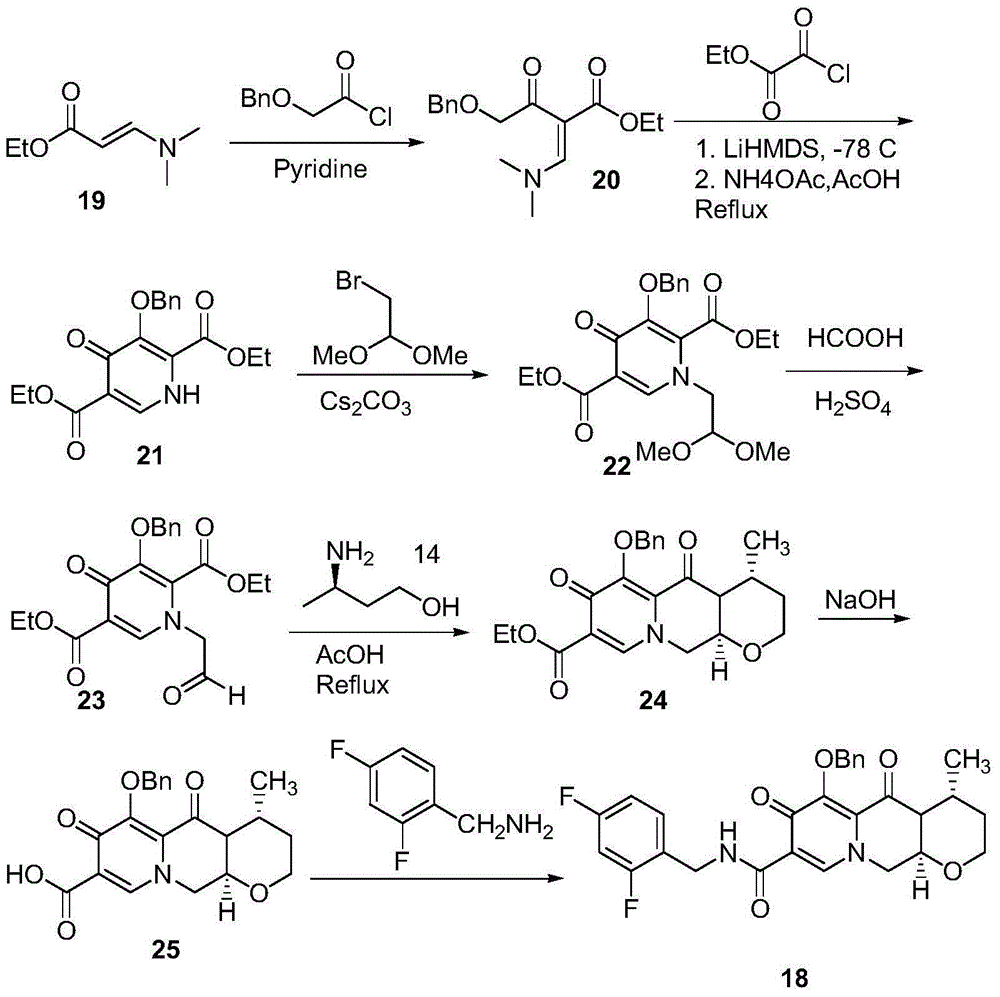

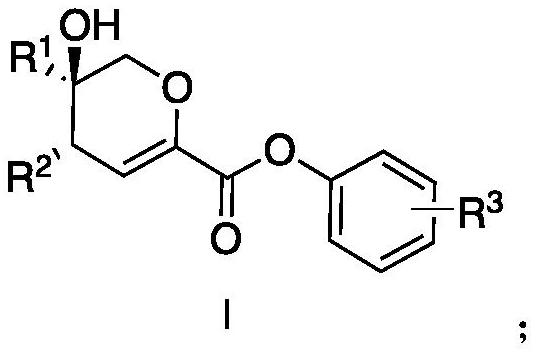

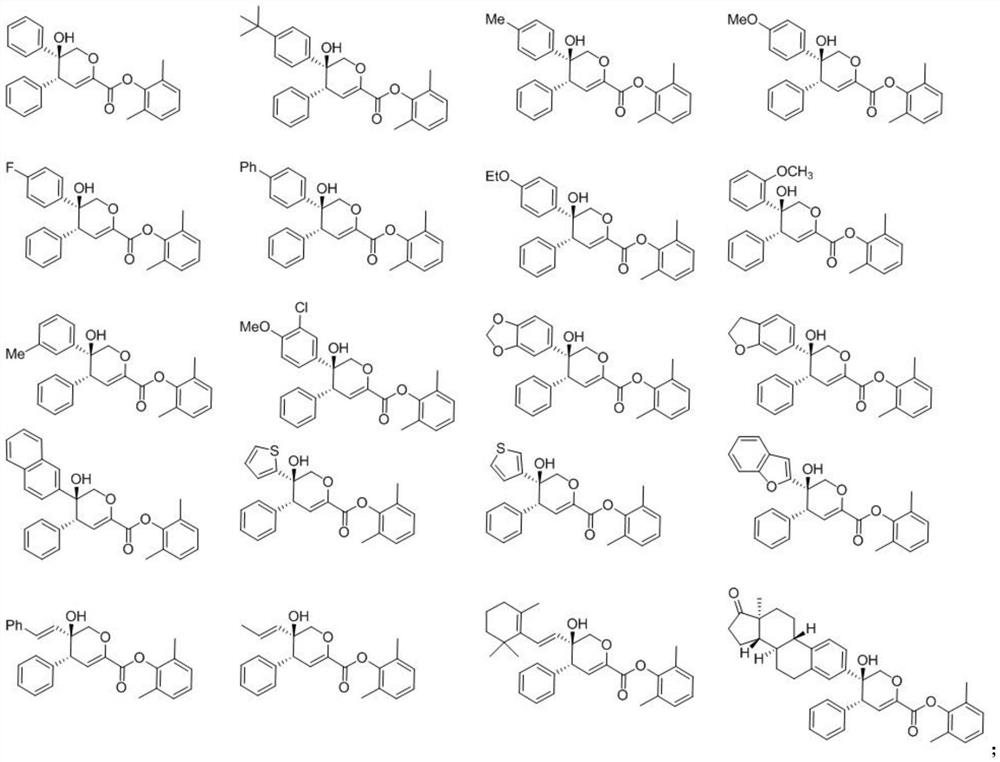

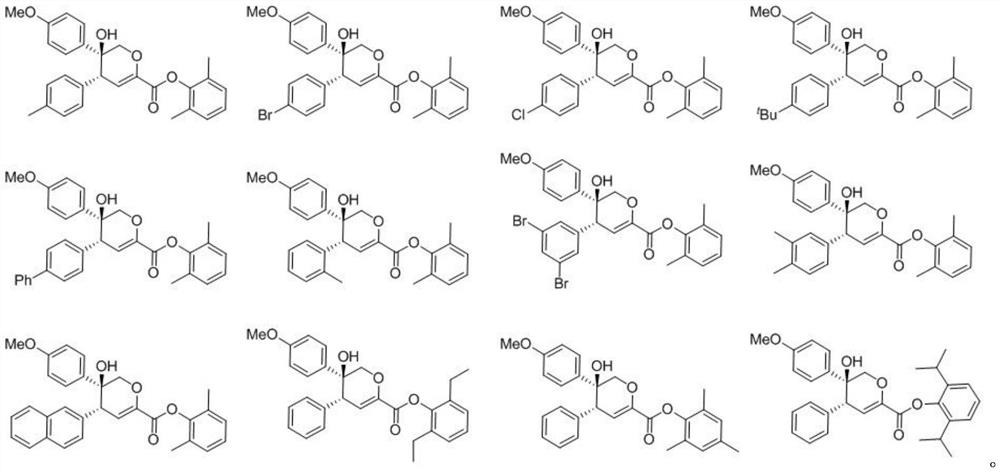

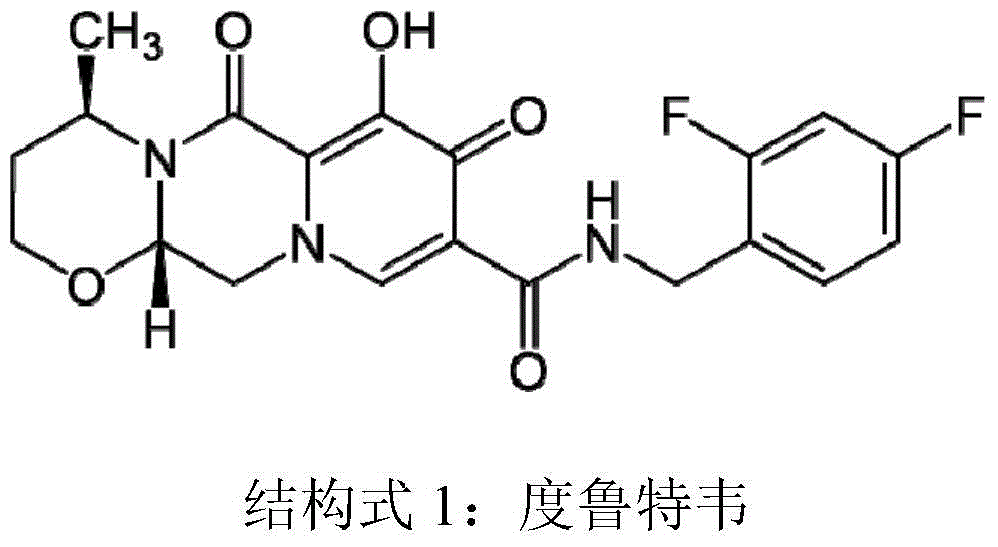

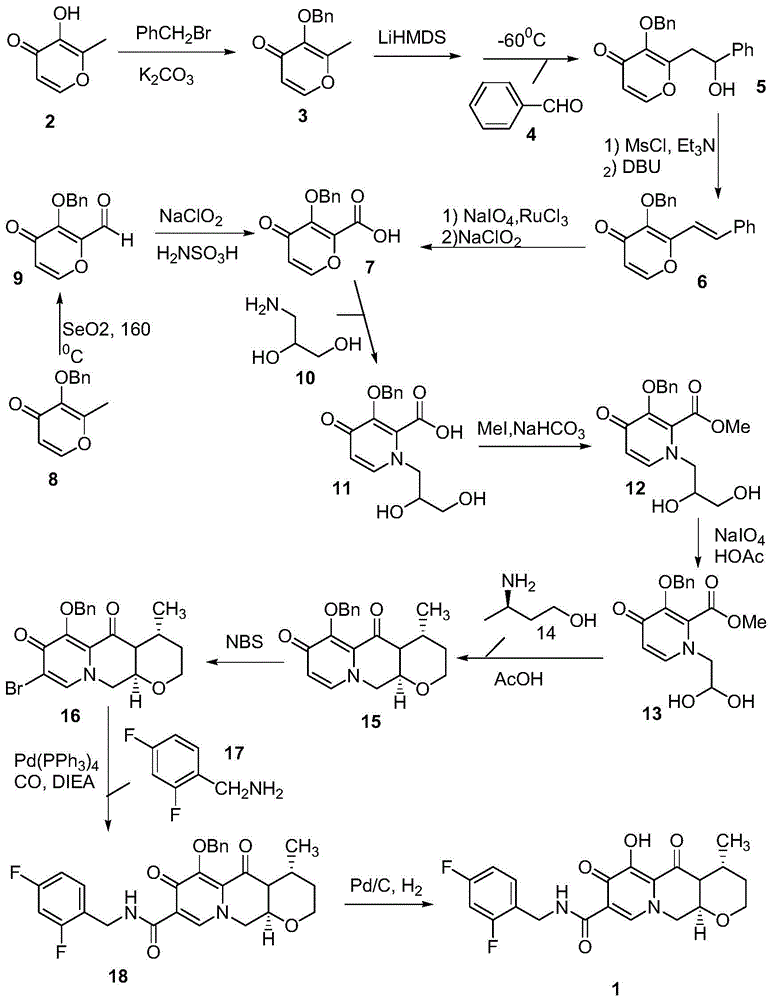

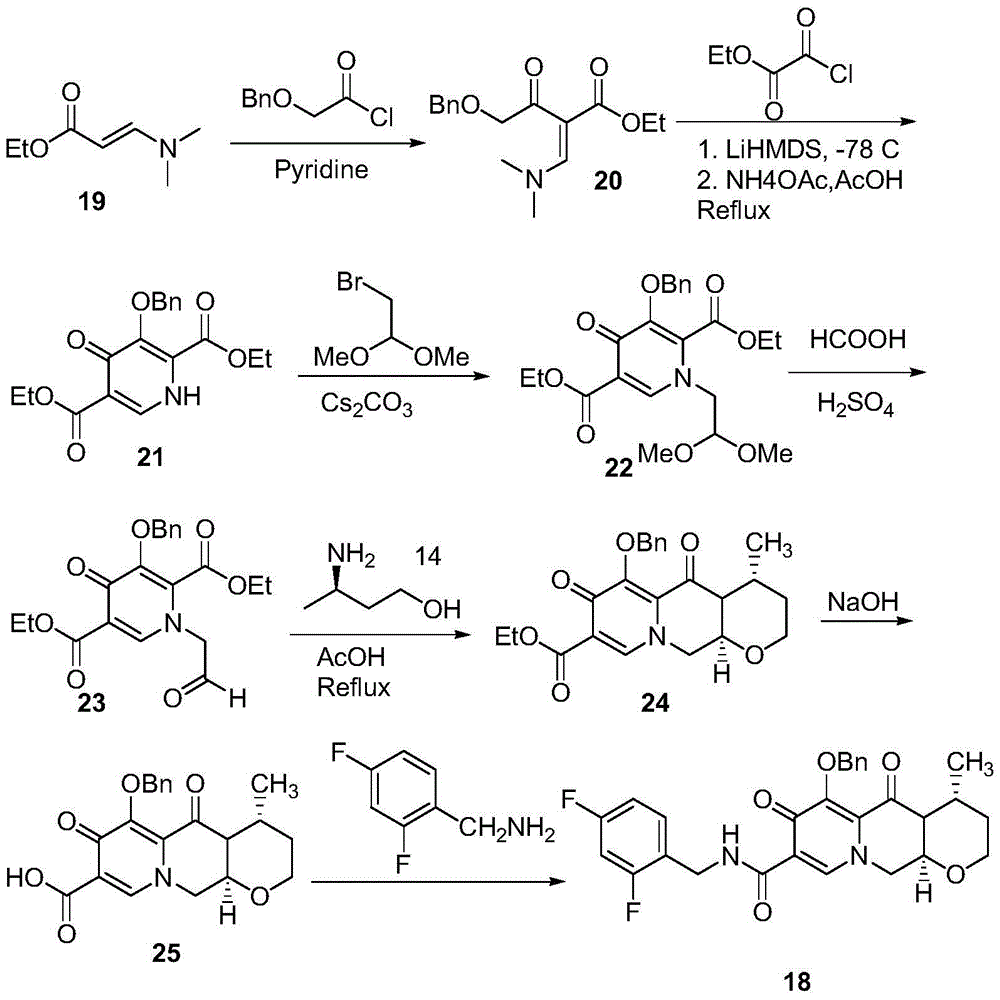

Chiral dihydropyran ring derivative as well as preparation method and application thereof

ActiveCN112920149ANovel structureImprove anti-tumor effectOrganic active ingredientsOrganic chemistryOncologyTumor cells

The invention belongs to the technical field of medicinal chemistry, and particularly relates to a chiral dihydropyran ring derivative and a preparation method and application thereof. The chiral dihydropyran ring derivative has the structure shown in the formula (I), the derivative is novel in structure, has a good anti-tumor effect, has a good inhibition effect on human osteosarcoma cells, human colon cancer cells and human non-small cell lung cancer cells, and especially has an excellent inhibition effect on the human non-small cell lung cancer cells. The inhibition IC50 of the derivative can be as low as 7 [mu]M. The derivative has a great application value in the anti-tumor effect aspect, and is expected to be prepared into anti-tumor drugs or drugs for inhibiting tumor cell proliferation, especially drugs for resisting human osteosarcoma, human colon cancer and human non-small cell lung cancer. Meanwhile, the preparation method disclosed by the invention has the advantages of cheap and easily available raw materials, few reaction steps, simplicity and safety in operation, low cost, few generated wastes, high atom economy, high selectivity and high yield.

Owner:SUN YAT SEN UNIV

A kind of preparation method of optically active 3-aminobutanol and 3-aminobutyric acid

ActiveCN104370755BNon-hazardousImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationSolventButyric acid

The present invention discloses a preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid. The optical activity active 3-amino butanol preparation method comprises: in a solvent, under effects of a hydroboration reduction agent and a Lewis acid, carrying out a reduction reaction on a compound represented by a formlu 65 to produce a compound represented by a formlu 14. The optical activity active 3-amino butyric acid preparation method comprises: carrying out a hydrolysis reaction on a compound represented by a formlu 64 to produce a compound represented by a formlu 65. According to the present invention, the preparation method has characteristics of cheap and easily-available raw materials, simple operation, short process route, no hazard of raw materials, high yield, little waste production, environment protection, high raw material conversion rate, high product chemical purity and high product optical purity, and the industrialization is easily achieved. The formulas 64, 65 and 14 are defined in the instruction.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

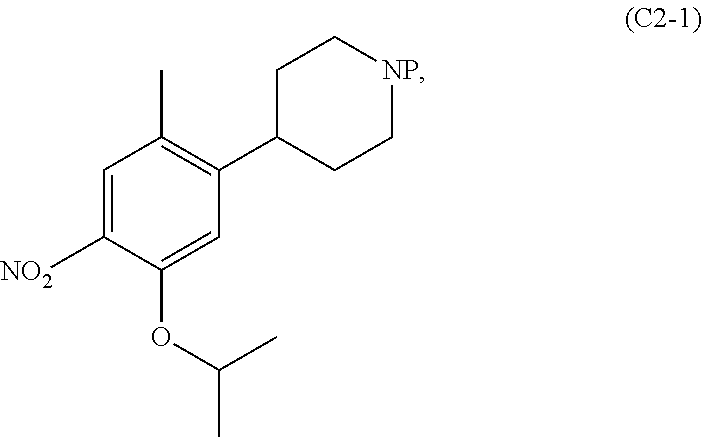

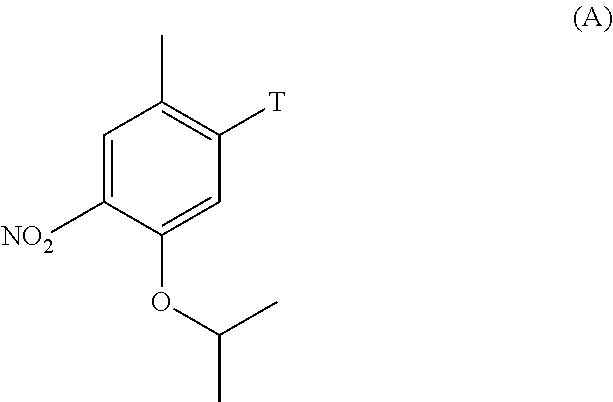

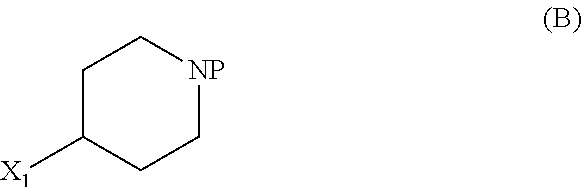

Chemical Process for Preparing Pyrimidine Derivatives and Intermediates Thereof

InactiveUS20180057457A1Cost efficientGenerate less wasteOrganic active ingredientsOrganic chemistryMethyl groupPropane

The present disclosure relates to a method of synthesizing 5-chloro-N2-(2-isopropoxy-5-methyl-4-(piperidin-4-yl)phenyl)-N4-[2-(propane-2-sulfonyl)-phenyl]-pyrimidine-2,4-diamine (ceritinib) and / or intermediates thereof, their use as pharmaceuticals and pharmaceutical compositions and the use of intermediates for preparing ceritinib.

Owner:NOVARTIS AG

Automatic displacement production device of silent bearing cage

ActiveCN105107993BAchieve shiftReduce breakage rateShaping toolsPerforating toolsHydraulic cylinderPunching

The invention provides an automatic shifting producing device for a silent bearing retainer. The device comprises a feeding assembly, a shifting assembly, a forming die, a shaping die and a punching die, wherein the feeding assembly comprises a feeding hydraulic cylinder, a position fixing plate and a pushing plate; the shifting assembly comprises a first transverse guide rod, a second transverse guide rod, a left longitudinal guide rod, a right longitudinal guide rod, a transverse returning spring and a longitudinal returning spring; the forming die comprises an upper forming die and a lower forming die; the shaping die comprises an upper shaping die and a lower shaping die; the punching die comprises an upper punching die and a lower punching die; the upper punching die comprises a punching propping plate, punching pins and a guide plate, wherein the punching pins are arranged as a circle; a plurality of guide holes through which the punching pins pass are formed in the guide plate; a circular clamping groove is formed in the bottom part of the guide plate; a circular supporting groove for storing the silent bearing retainer is formed in the top part of the lower punching die. The device is reasonable in structural design, enables automatic shifting of a workpiece in processing, is high in processing accuracy, produces few wastes, and is beneficial for production and application.

Owner:宁波优斯凯精密机械有限公司

Preparation method of intermediate compound of pregabalin

ActiveCN102464594BImprove conversion rateHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationArylAlkoxy group

The invention discloses a preparation method for preparing an intermediate compound II of pregabalin. The preparation method of the intermediate compound II comprises the following steps of: (1) undergoing an SN2 substitution reaction on a compound VI and XCH2COOR2 to obtain a compound I; and (2) undergoing a Wittig-Hornor reaction on the compound I obtained in the step (1) and isobutylaldehyde, wherein R1 is alkoxyl with 1-6 carbon atoms or aryl with 6-10 carbon atoms; X is halogen; and R2 is alkyl with 1-6 carbon atoms. The invention further relates to a preparation method for preparing an intermediate compound V of pregabalin. The preparation method of the intermediate compound V comprises the following step of: undergoing an asymmetric hydrogenation reaction on the compound IV and hydrogen gas in a solvent under the action of [Rh((Sc,Rp)-Duanpos)(COD)]BF4, wherein M is H, alkyl with 1-6 carbon atoms or t-BuNH<3+>.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

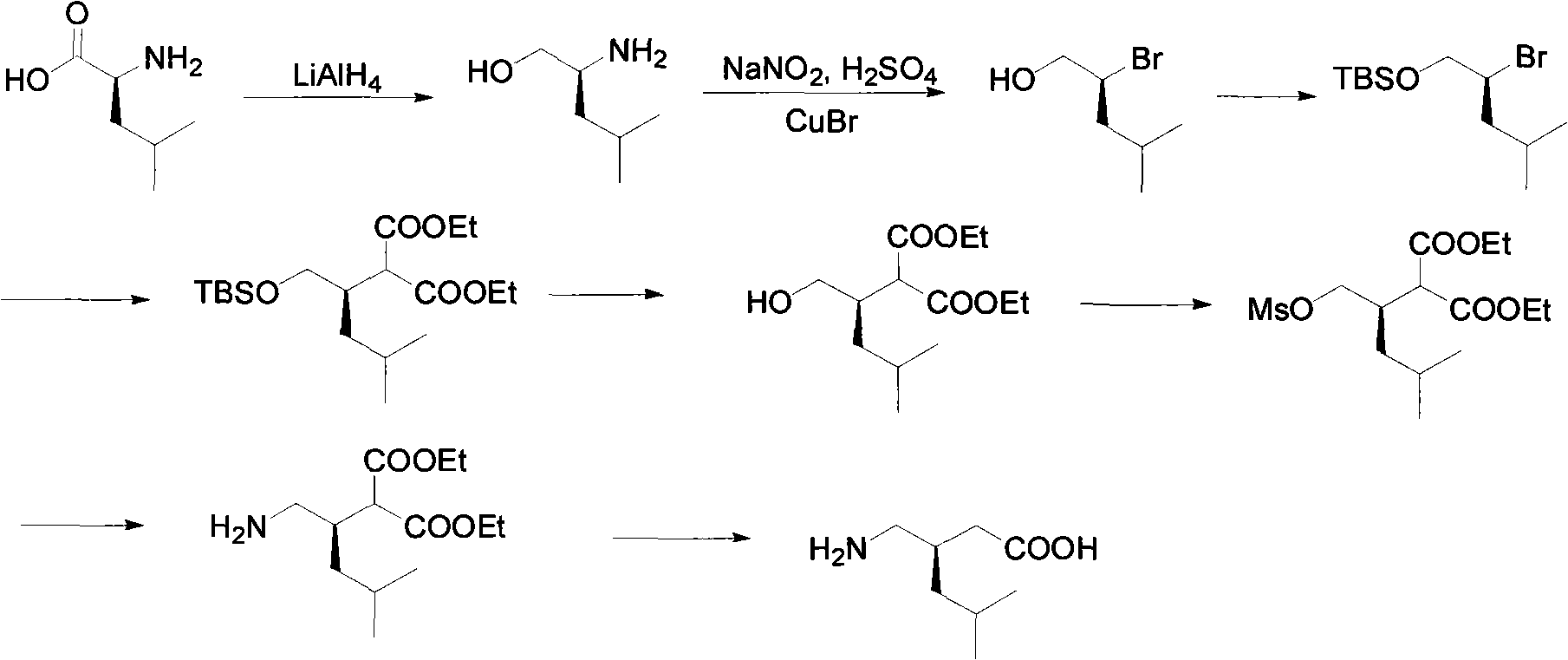

Method of preparing monobutyl tin trichloride and dibutyl tin dichloride from low purity tributyl tin chloride

PendingCN109824717AFully recycleBig difference in melting pointTin organic compoundsTetrachlorideDibutyltin dichloride

The invention discloses a method of preparing monobutyl tin trichloride and dibutyl tin dichloride from low purity tributyl tin chloride. The method comprises following steps: (1) mixing tributyl tinchloride with a purity lower than 95% with tin tetrachloride, controlling the temperature to carry out reactions to obtain a mixture composed of monobutyl tin trichloride and dibutyl tin dichloride; and (2) distilling and separating the mixture obtained in the step (1) to obtain monobutyl tin trichloride and dibutyl tin dichloride. Low purity and waste tributyl tin chloride is fully utilized to generate monobutyl tin trichloride and dibutyl tin dichloride that can be used, the cost for processing sewage of organic tin catalysts is reduced, and the utilization rate is improved.

Owner:南通濠泰化工产品有限公司

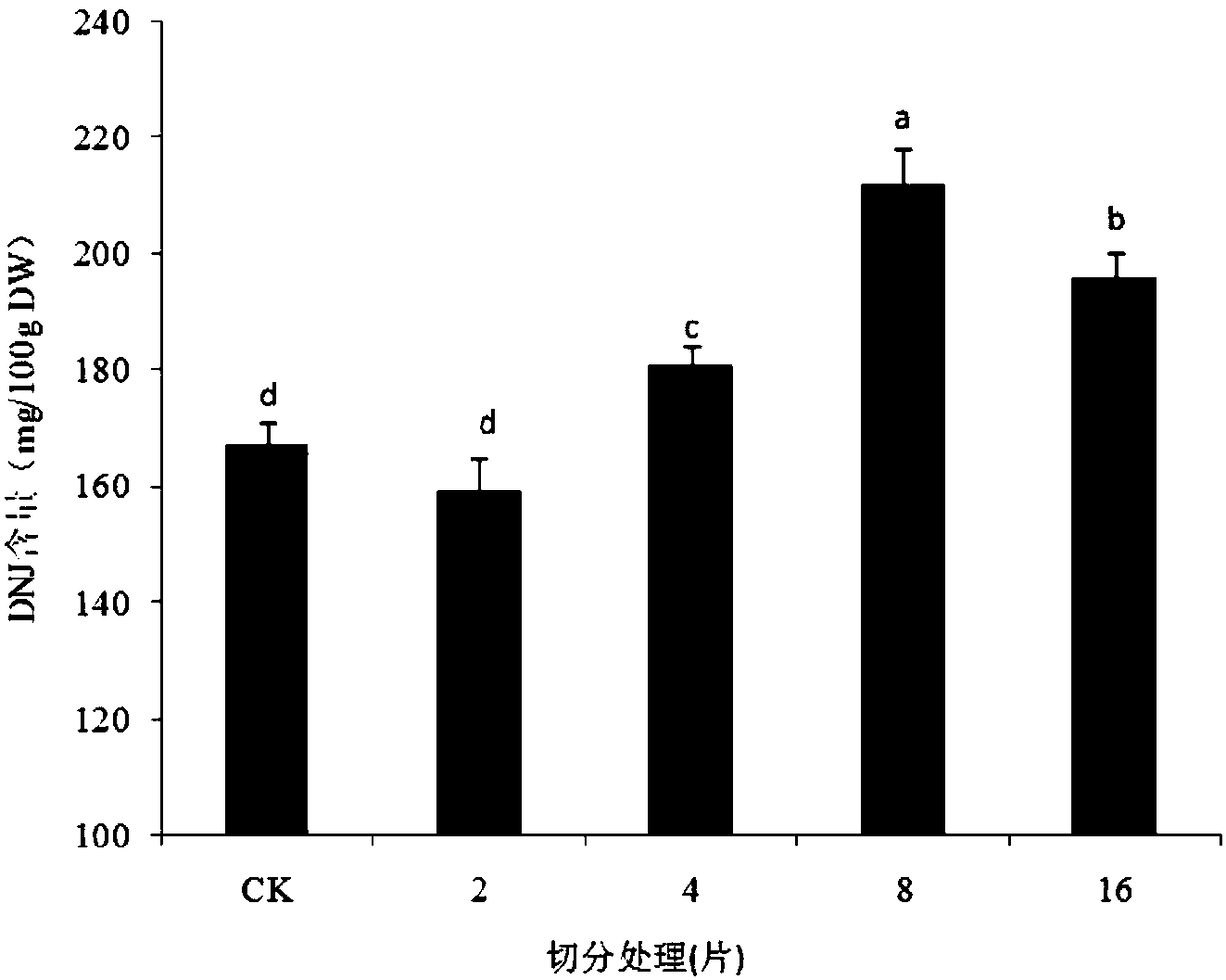

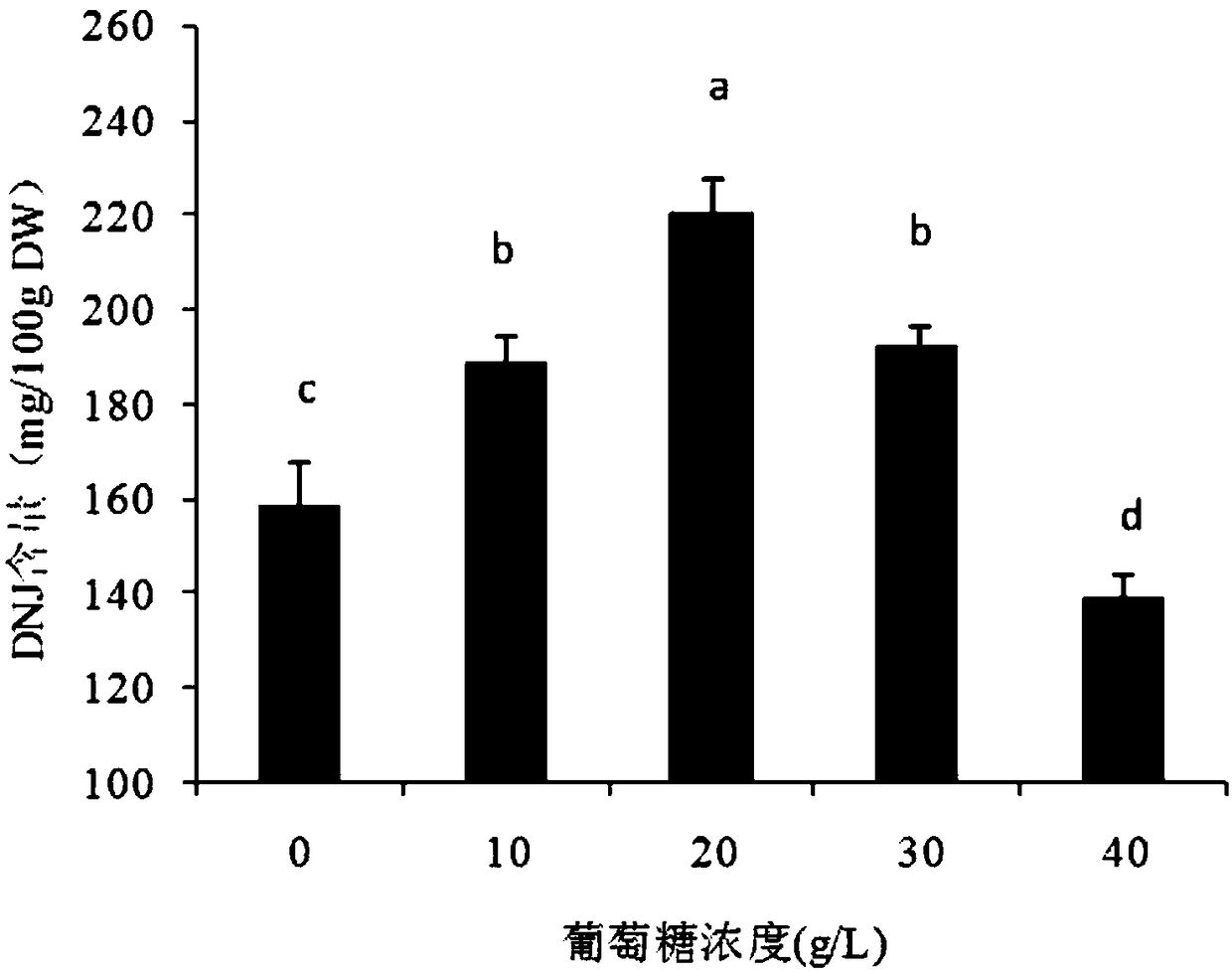

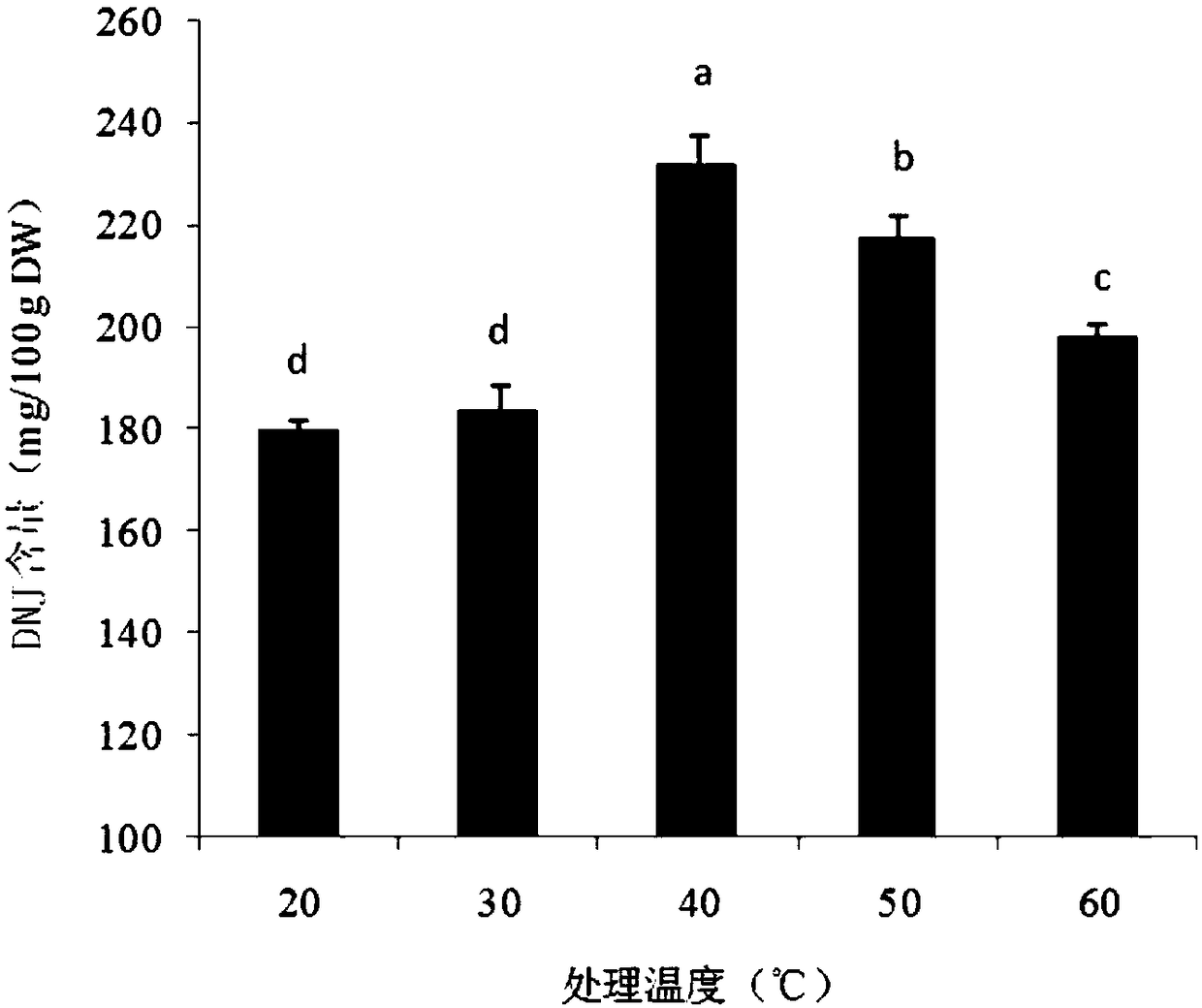

A method for enriching 1-deoxynojirimycin in mulberry leaves and the obtained ultrafine powder

ActiveCN105520152BImprove absorption and utilizationIncrease contentFood ingredient functionsUltra fineGlucose polymers

The present invention relates to a 1-deoxynojirimycin enriched mulberry leaf preparation method and an obtained ultra-fine powder, which belongs to the processing field of medicinal and edible food. Fresh and complete tender mulberry leaves are washed, air-dried and cut into slice shapes with a length and width of 3-6 cm*3-6 cm, the mulberry leaf broken slices are soaked in a glucose solution at a temperature of 30-60 DEG C and a concentration of 10-30 g / L for 3-5 hours, the taken mulberry broken slices are dried to a water content to below 5%, the dried mulberry broken slices are crushed into an average particle size of 8 [mu]m or less, and the crushed mulberry leaves are dried to a water content to below 5%, thereby obtaining the 1-deoxynojirimycin enriched mulberry leaf ultra-fine powder. During the fresh mulberry leaf soaking process, endogenous DNJ synthesis related enzymes are activated and the glucose is catalyzed to enrich DNJ. The highest content of the finished product of the DNJ is 250mg / 100g. The obtained product by the method is clear in health-care function and safe and reliable in consumption.

Owner:镇江市智农食品有限公司

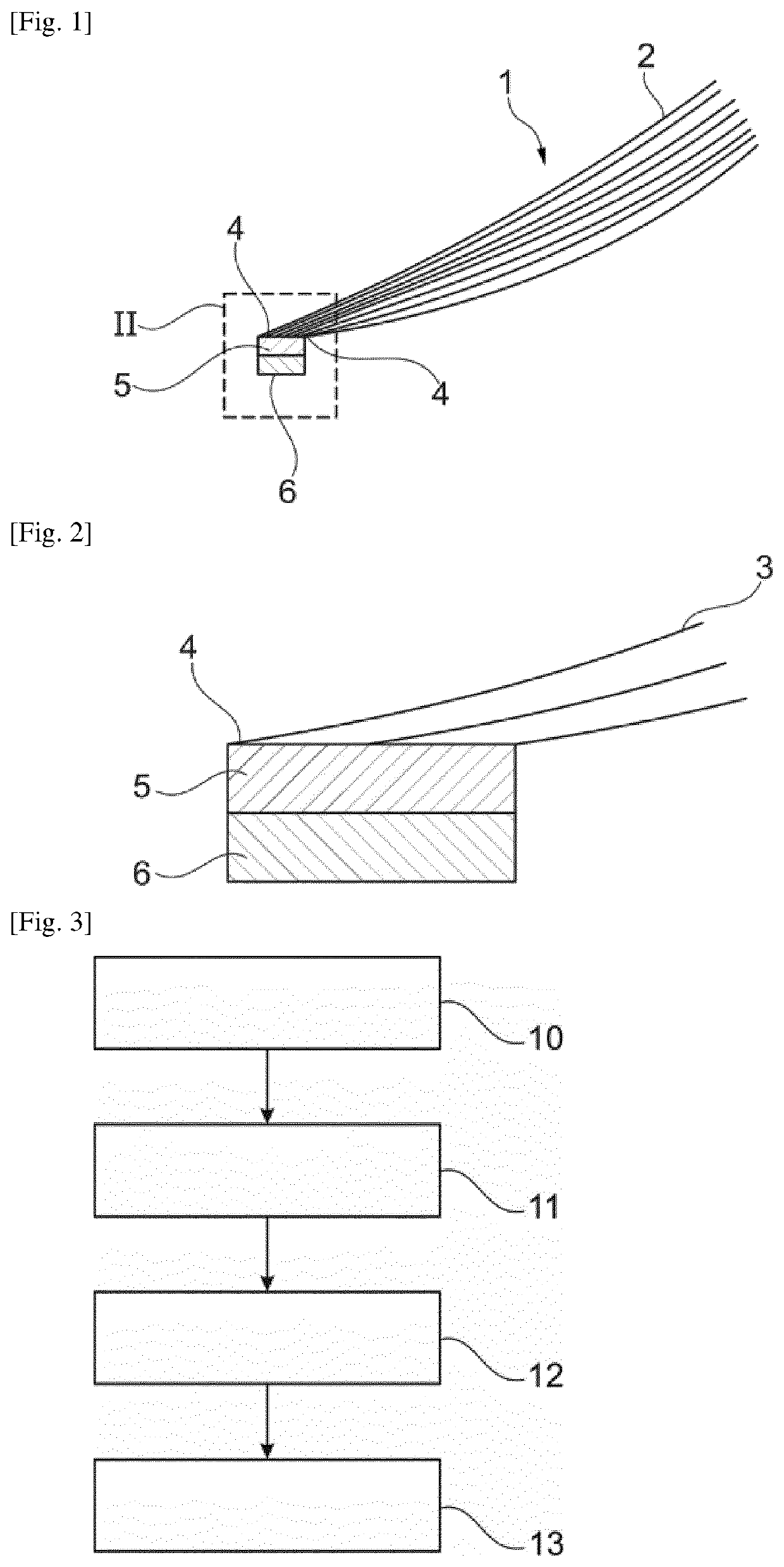

Cosmetic article

Cosmetic article (1) for application to the eyelid, the eyelashes and / or the eyebrows, including:—at least one element (2) to be applied,—at least one adhesive layer (5) which is at least partially in contact with the element (2) to be applied, this adhesive layer (5) including at least one water-resistant adhesive material, and—at least one layer (6) for protecting the adhesive layer (5), externally covering same and including at least one water-soluble polymer.

Owner:LOREAL SA

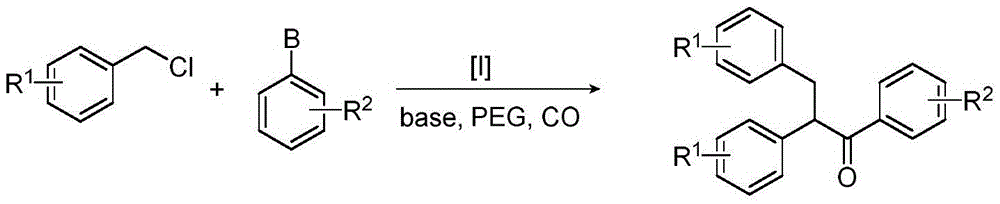

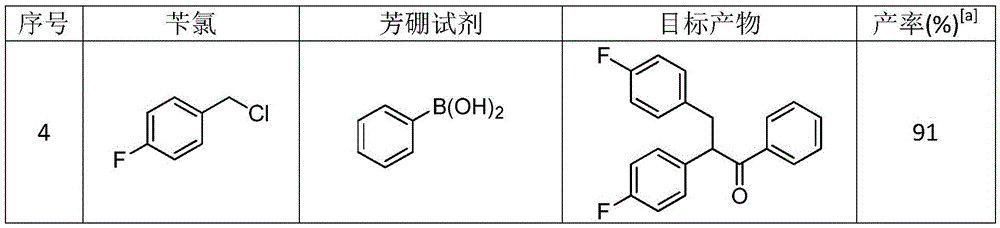

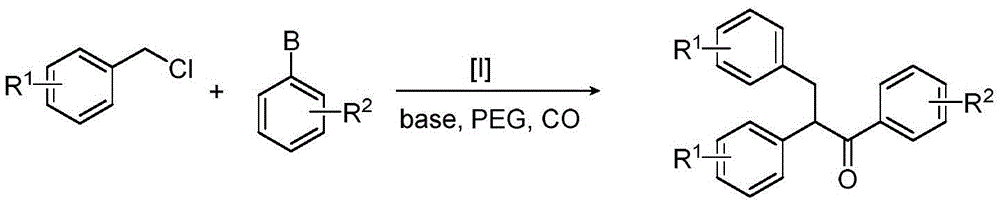

Method for synthesizing 1,2,3-triaryl-1-acetone compound from benzyl chloride through non-metal-catalyzed carbonylation

InactiveCN105669400AWide range of substrate sourcesGenerate less wasteOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCarbonyl groupBenzyl chloride

The invention discloses a method for synthesizing a 1,2,3-triaryl-1-acetone compound from benzyl chloride through non-metal-catalyzed carbonylation. According to the method, carbon monoxide is taken as a carbonyl source, and an iodine catalyst is utilized for catalyzing carbonylation-alkylation domino reaction of benzyl chloride and an aryl boron reagent in medium polyethylene glycol in the presence of the iodine catalyst and alkali so as to directly prepare the 1,2,3-triaryl-1-acetone compound. In the method, noble metal catalysts and ligands are not used, and the reaction can be carried out under the normal pressure; and the method has the advantages that a substrate is wide in source, stable and low in cost, the catalyst is low in cost and easily available, little waste is produced, the application range is wide, the reaction selectivity is high, and the yield of the target product is high.

Owner:NANJING NORMAL UNIVERSITY

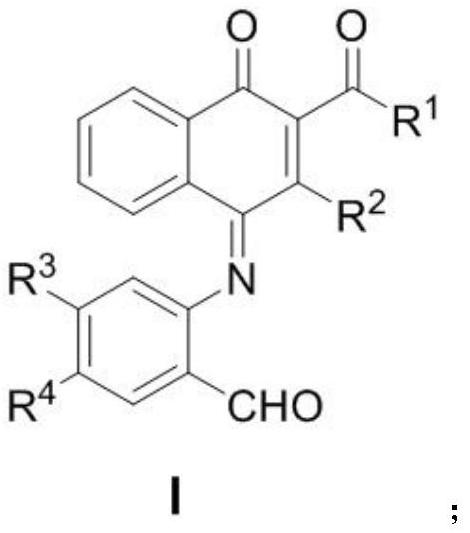

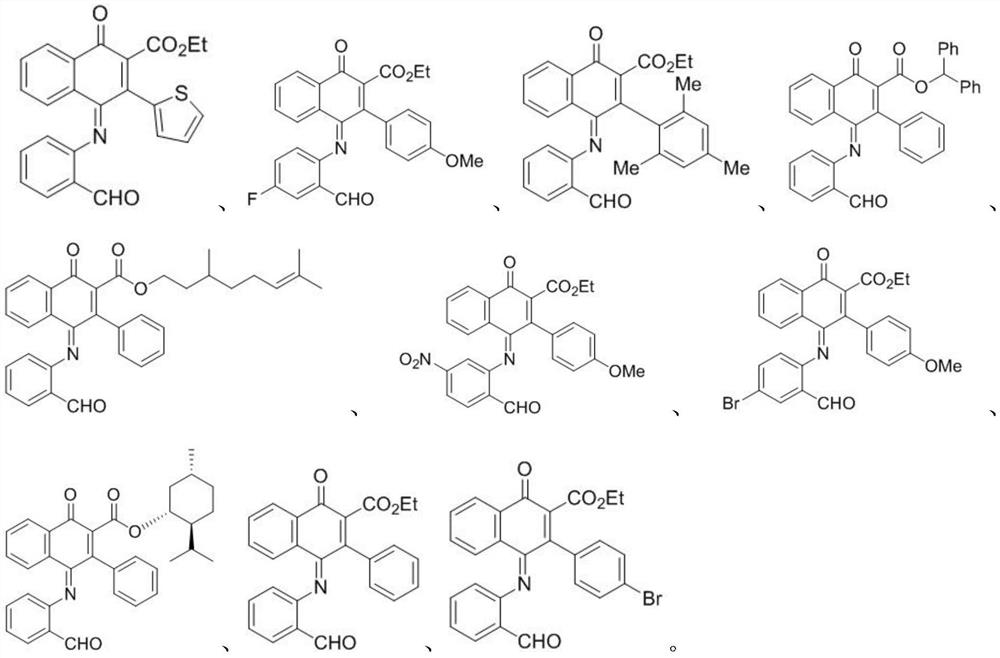

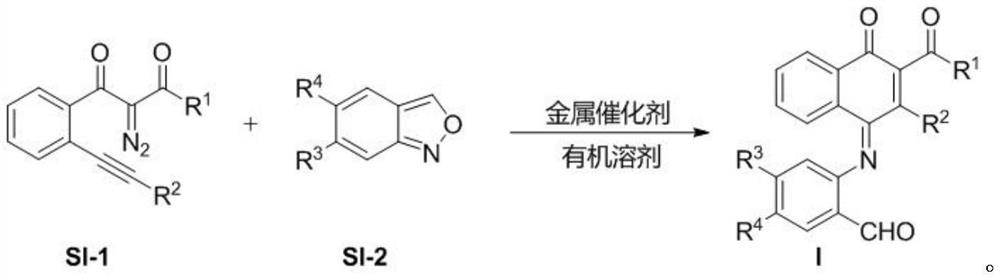

A kind of polysubstituted naphthoquinone derivatives and its preparation method and application

ActiveCN113292532BNovel structureImprove anti-tumor effectOrganic active ingredientsAntineoplastic agentsPhenyl groupTrimethyl benzene

The invention belongs to the technical field of medicinal chemistry, and specifically relates to a multi-substituted naphthoquinone derivative and its preparation method and application. The structure of the derivative is shown in the general formula (I), wherein, R 1 selected from ethoxy, diphenylmethoxy, linalyl, D-menthol; R 2 selected from thiophene, phenyl, p-bromophenyl, p-methoxyphenyl, 2,4,6-trimethylphenyl; R 3 selected from hydrogen, nitro; R 4 Selected from hydrogen, fluorine, and bromine; the derivative has a novel structure and has a good antitumor effect, especially has a good inhibitory effect on colorectal adenocarcinoma cells, osteosarcoma cells and breast cancer cells. It has great application value and is expected to be prepared as an antitumor drug; at the same time, the preparation method of the polysubstituted naphthoquinone derivative has fewer reaction steps, simple and safe operation, low cost, less waste generation, high atom economy, and high selectivity. Sex, the advantage of high yield.

Owner:SUN YAT SEN UNIV

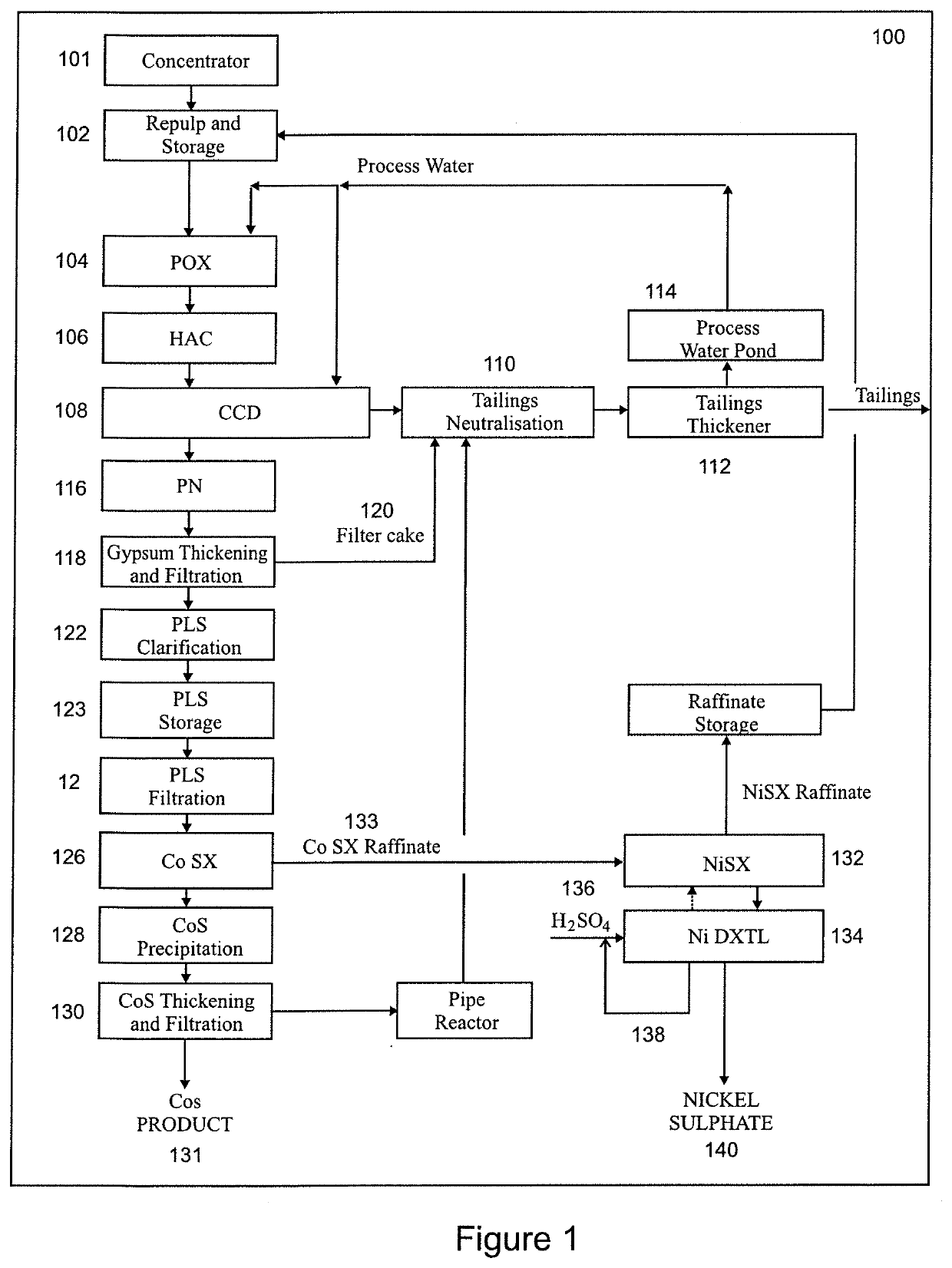

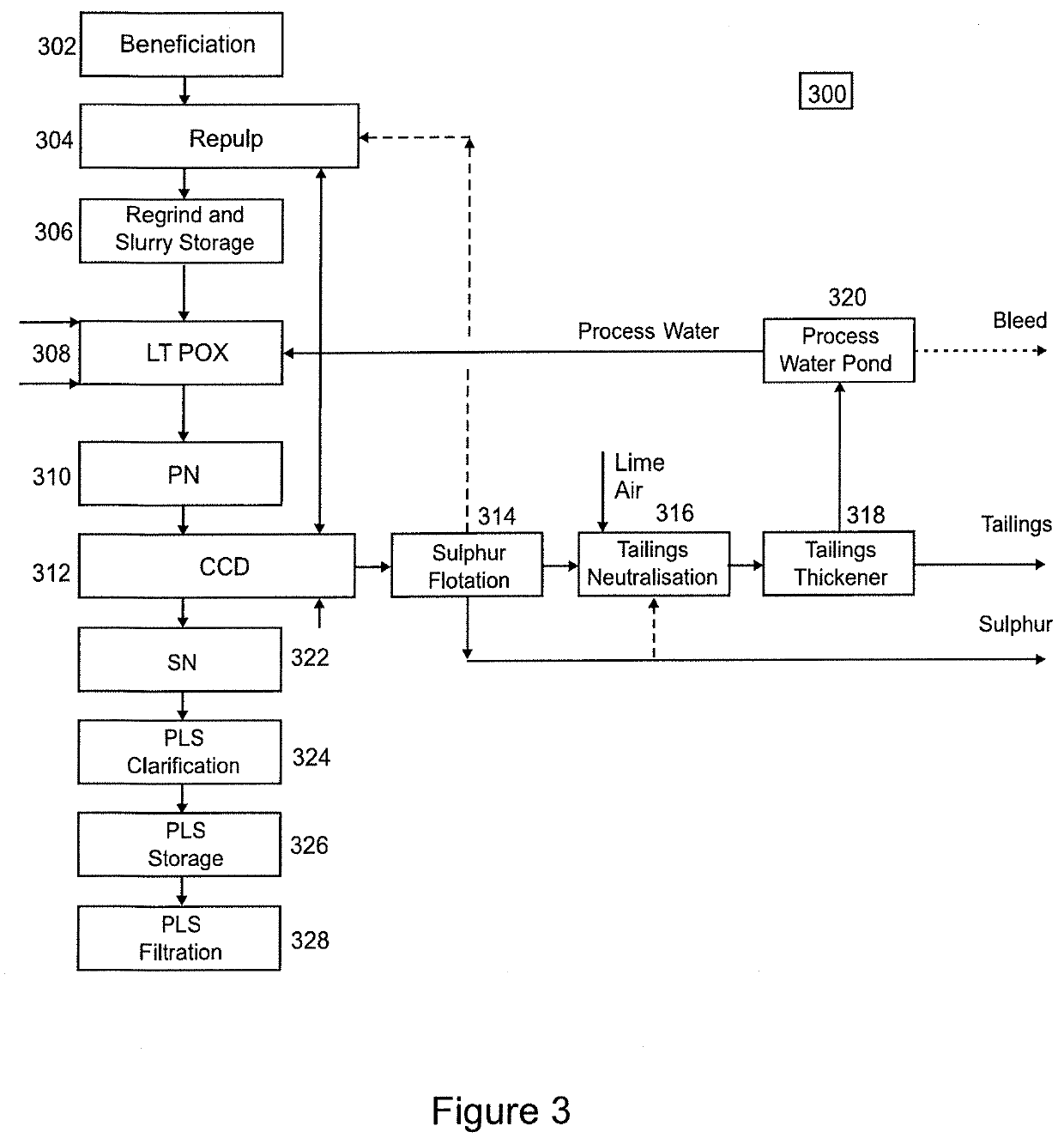

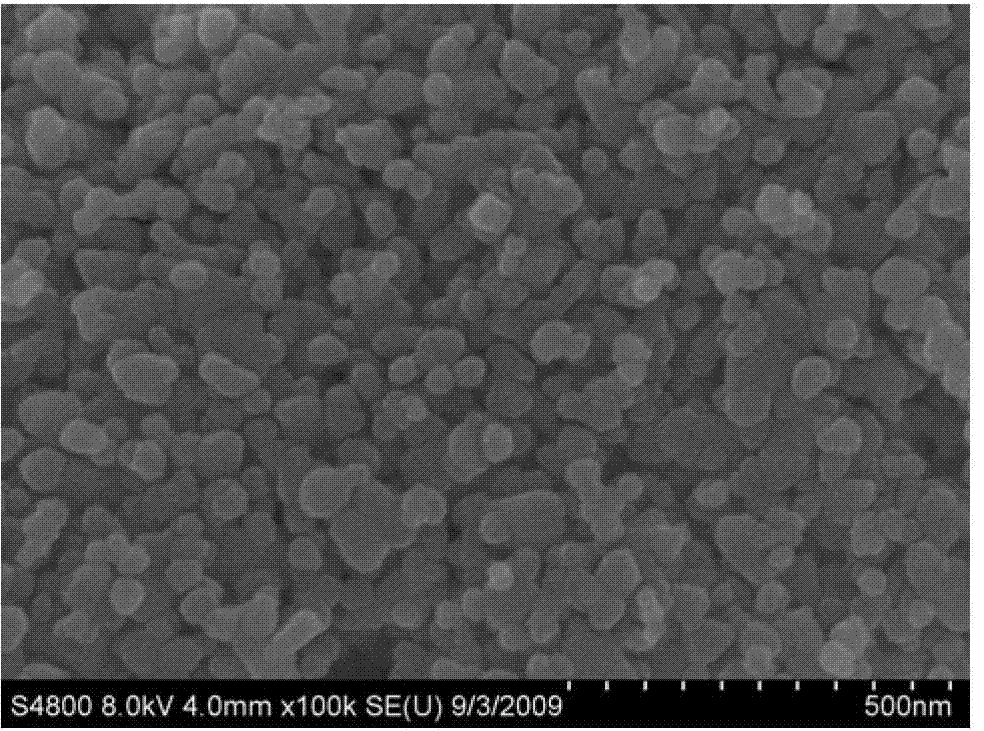

Method for preparing a high-purity hydrated nickel sulphate

PendingUS20210354997A1Increase concentrationImprove concentrationNickel compounds preparationNickel sulfatesPregnant leach solutionPhysical chemistry

A method for recovering NiSO4.6H2O crystals from a nickel rich organic phase is provided. The method includes contacting a nickel rich organic phase with an aqueous strip solution of sufficient H2SO4 concentration to extract nickel from the organic phase and of sufficient Ni2+ concentration to precipitate NiSO4.6H2O crystals and form a nickel lean organic phase. Also provided are methods for recovering NiSO4.6H2O crystals that include preceding processing steps, including low temperature pressure oxidation (LTPOX) autoclaving of a nickel sulphide concentrate to afford a pregnant leach solution (PLS).

Owner:IGO LTD

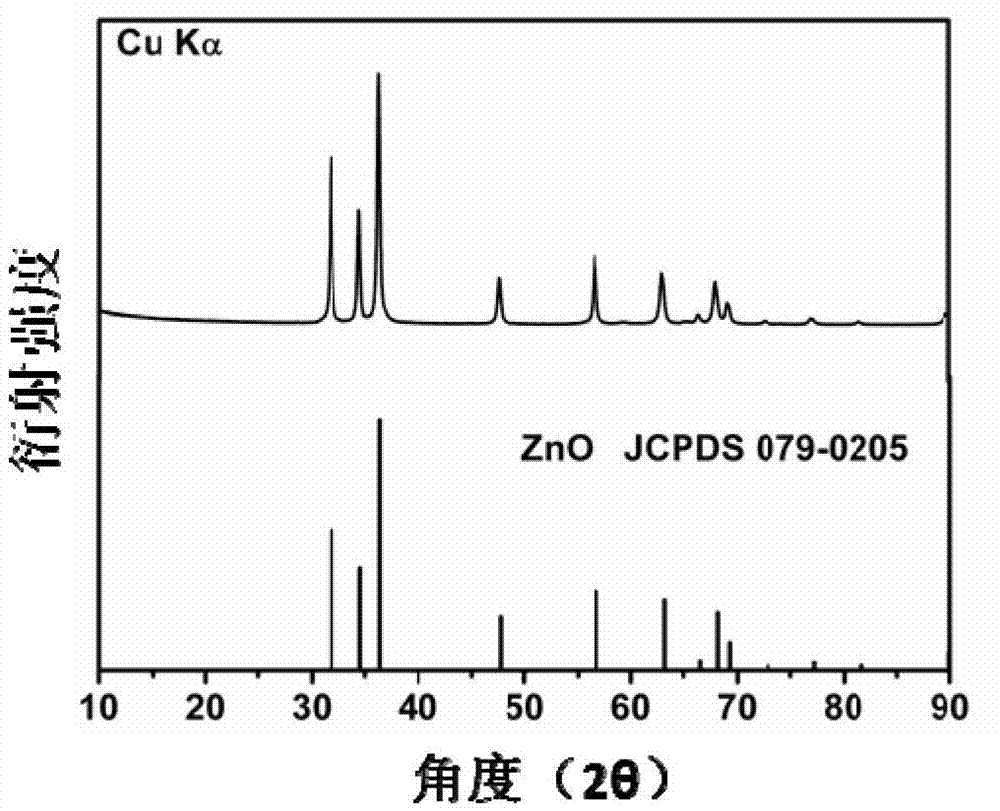

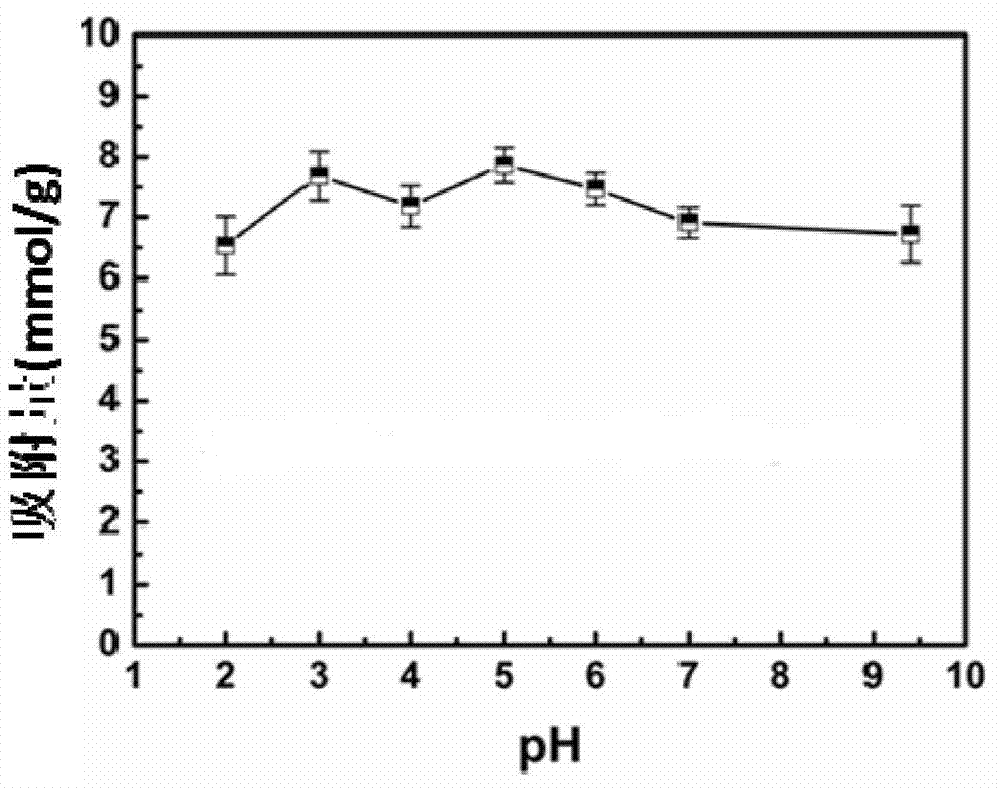

Method for removing methyl blue dye in wastewater

InactiveCN103172187BMaterials are cheap and readily availableQuick removalMultistage water/sewage treatmentWaste water treatment from textile industryWastewaterMethyl blue

Owner:NINGBO UNIV

Automatic shifting producing device for silent bearing retainer

ActiveCN105107993AAchieve shiftReduce breakage rateShaping toolsPerforating toolsHydraulic cylinderPunching

The invention provides an automatic shifting producing device for a silent bearing retainer. The device comprises a feeding assembly, a shifting assembly, a forming die, a shaping die and a punching die, wherein the feeding assembly comprises a feeding hydraulic cylinder, a position fixing plate and a pushing plate; the shifting assembly comprises a first transverse guide rod, a second transverse guide rod, a left longitudinal guide rod, a right longitudinal guide rod, a transverse returning spring and a longitudinal returning spring; the forming die comprises an upper forming die and a lower forming die; the shaping die comprises an upper shaping die and a lower shaping die; the punching die comprises an upper punching die and a lower punching die; the upper punching die comprises a punching propping plate, punching pins and a guide plate, wherein the punching pins are arranged as a circle; a plurality of guide holes through which the punching pins pass are formed in the guide plate; a circular clamping groove is formed in the bottom part of the guide plate; a circular supporting groove for storing the silent bearing retainer is formed in the top part of the lower punching die. The device is reasonable in structural design, enables automatic shifting of a workpiece in processing, is high in processing accuracy, produces few wastes, and is beneficial for production and application.

Owner:宁波优斯凯精密机械有限公司

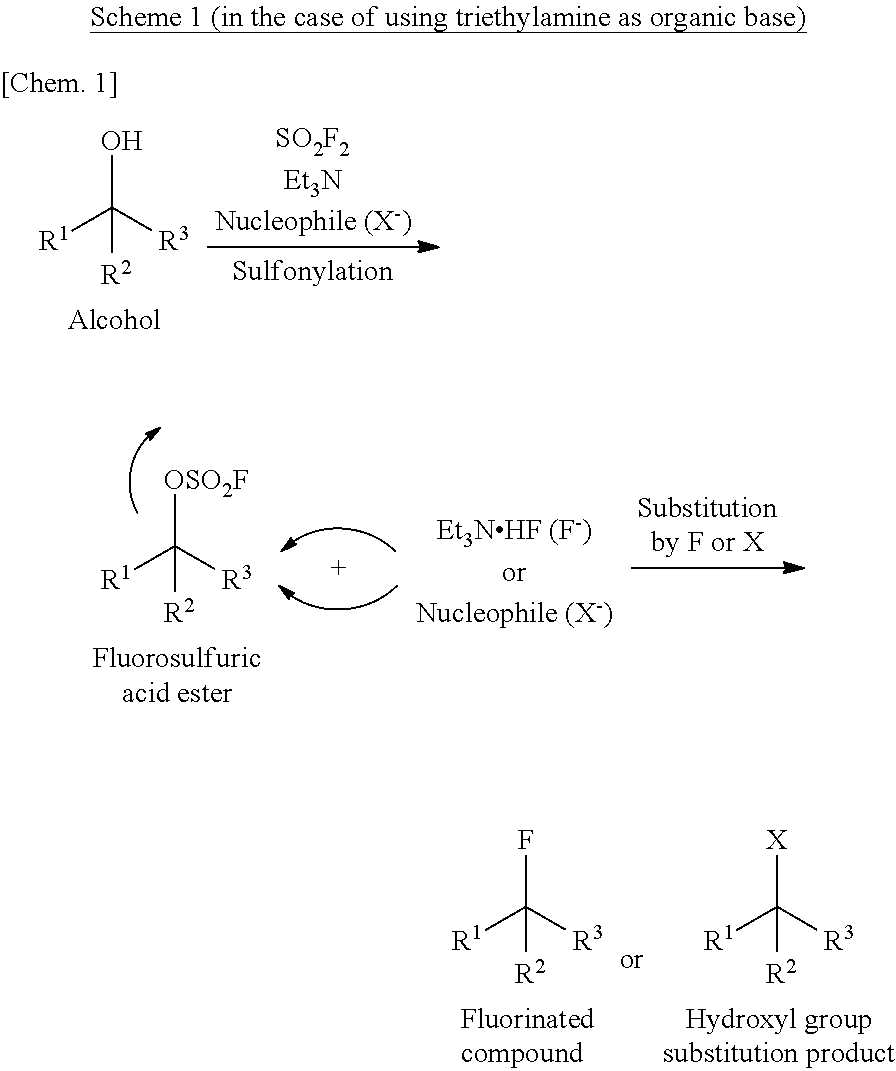

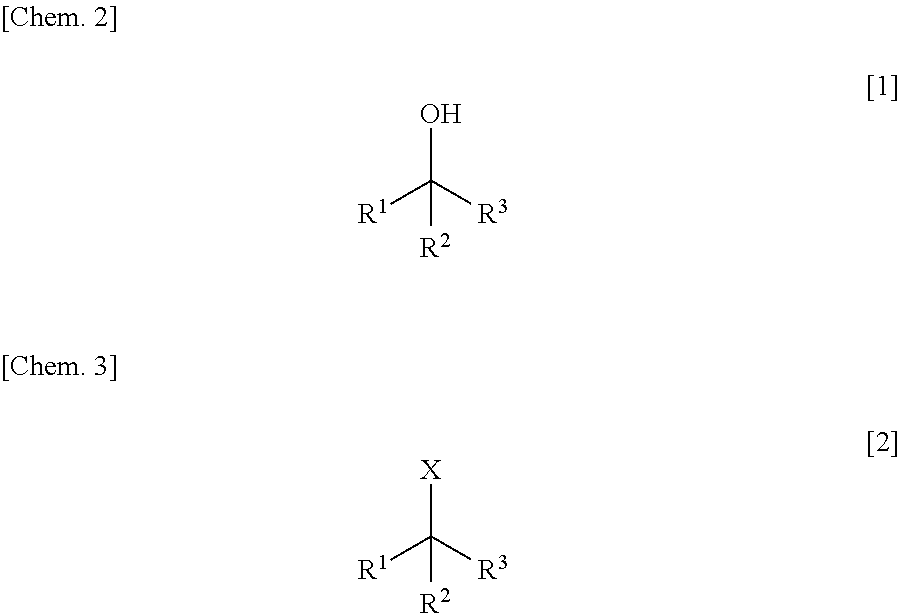

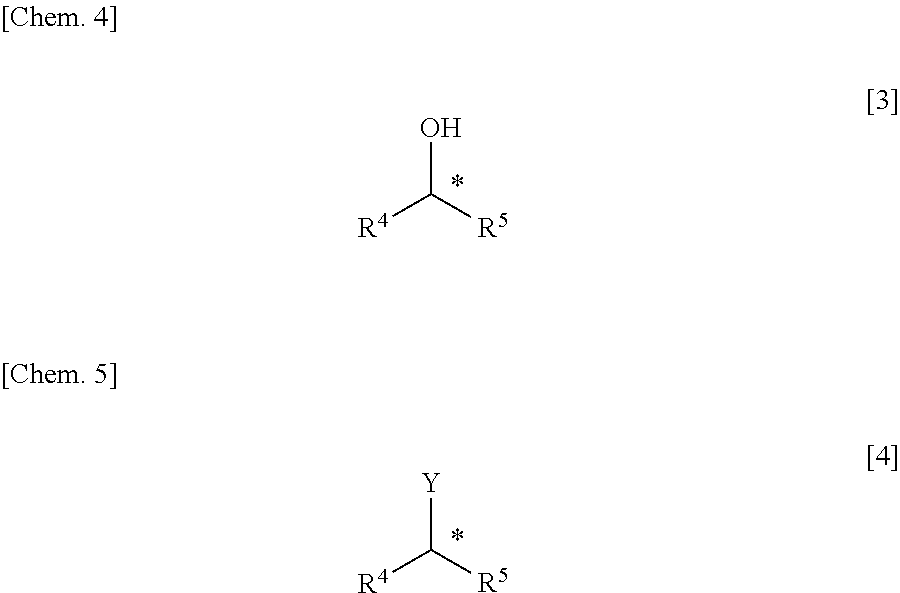

Method for Manufacturing Hydroxyl Group Substitution Product

InactiveUS20110251403A1Easy purification operationLess waste generationOrganic compound preparationCarboxylic acid esters preparationWaste generationOptically active

In the present invention, a hydroxyl group substitution product is manufactured by reaction of an alcohol with sulfuryl fluoride (SO2F2) in the presence of an organic base and a nucleophile (X−). The present invention is thus effective as an industrial manufacturing method that uses a relatively cheap reagent suitable for large-scale applications and can be accomplished in a simple process with easy purification operation and less waste generation and is suitably applicable for manufacturing of optically active hydroxyl group substitution products, notably optically active α-hydroxyl group substitution ester and optically active 4-hydroxyl group substitution proline. The manufacturing method of the present invention solves all of the prior art problems and can be applied for industrial uses.

Owner:CENT GLASS CO LTD

Method for the quantification of 227AC in 223RA compositions

ActiveUS9874550B2Fast and efficientGenerate less wasteIon-exchange process apparatusSpecific isotope recoveryActiniumSolid phase extraction

Owner:BAYER AS

Preparation method of hydroxy-terminated perfluoropolyether compound

ActiveCN102660012BEasy to separateHigh reaction yieldOrganic chemistryOrganic compound preparationActivated carbonPolymer science

The invention relates to a preparation method of a hydroxy-terminated perfluoropolyether compound. Perfluoropolyether carboxylic acid or ester used as a raw material is subjected to reducing reaction to obtain the hydroxy-terminated perfluoropolyether compound, wherein hydrogen is used as the reducer of the reducing reaction, an activated carbon supported ruthenium or rhodium catalyst is used as the catalyst, and the reaction is carried out at 80-200 DEG C under the pressure of 10-50MPa. Compared with the prior art, the invention has the advantages of high reaction yield, simple after-treatment and fewer three wastes, and is simple to operate.

Owner:太仓中化环保化工有限公司 +2

Method of manufacturing compound with biocatalyst by using controlled reaction temperature

InactiveUS7078199B2Efficient use ofIncrease productivityFermentationReaction temperatureOrganic chemistry

Provided is a method for producing a compound using a biocatalyst. In the method for continuously producing a compound using a biocatalyst in one or a plurality of reaction tanks, the downstream reaction temperature is set higher than the upstream reaction temperature of the flow of the catalyst in a reaction tank or between reaction tanks.

Owner:MITSUBISHI CHEM CORP

Forming and shaping integrated production equipment for silent bearing cages

ActiveCN105107937BRealize automatic shiftAvoid displacementShaping toolsPerforating toolsHydraulic cylinderPunching

The invention provides a forming and shaping integrated production device for a mute bearing retainer. The forming and shaping integrated production device for the mute bearing retainer comprises a feeding assembly, a movement assembly, a forming and shaping integrated die and a punching die. The feeding assembly comprises a feeding hydraulic cylinder, a position fixing plate and a pushing plate. The movement assembly comprises a first transverse guide rod, a second transverse guide rod, a left longitudinal guide rod, a right longitudinal guide rod, a transverse reset spring and a longitudinal reset spring. The feeding assembly, the forming and shaping integrated die and the punching die are sequentially arranged between the left longitudinal guide rod and the right longitudinal guide rod. The forming and shaping integrated die comprises an integrated upper die and an integrated lower die. The punching die comprises an upper punching die body and a lower punching die body. The forming and shaping integrated production device for the mute bearing retainer is reasonable in structural design, automatic movement can be achieved when workpieces are machined, the machining accuracy is high, a few waste materials are generated, and using for production is facilitated.

Owner:江苏盐新汽车产业投资发展集团有限公司

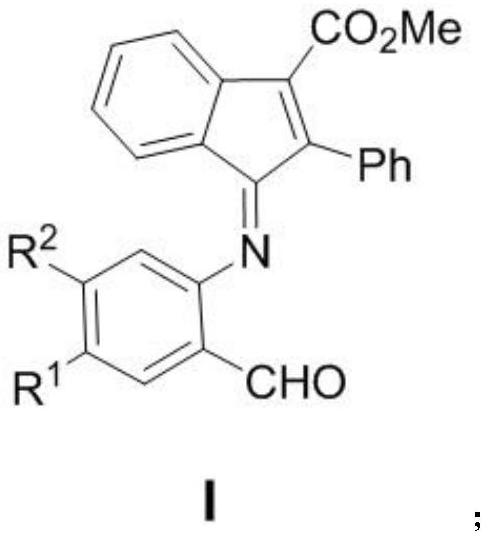

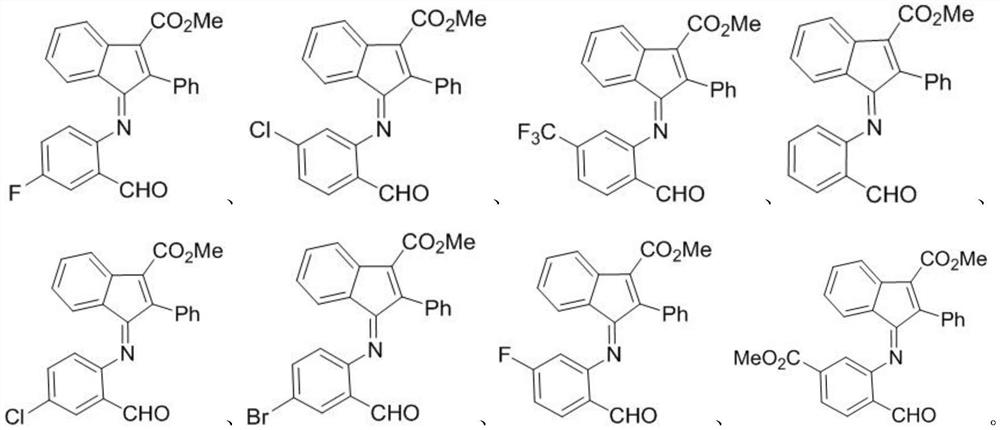

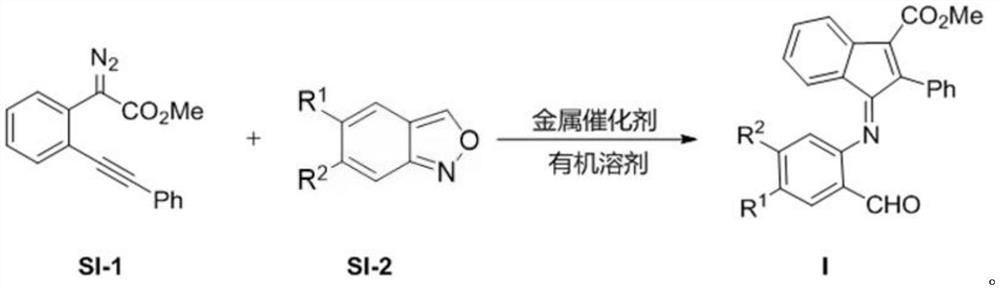

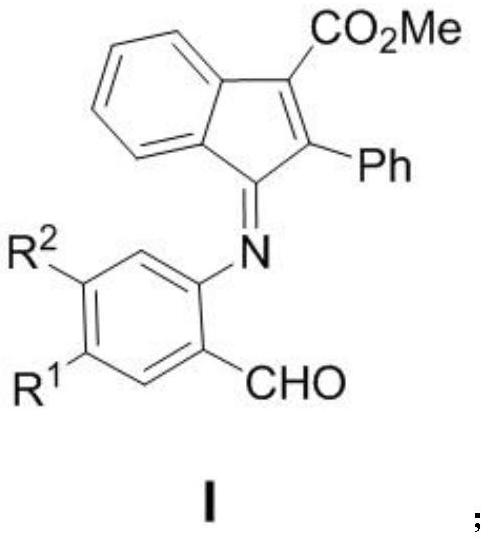

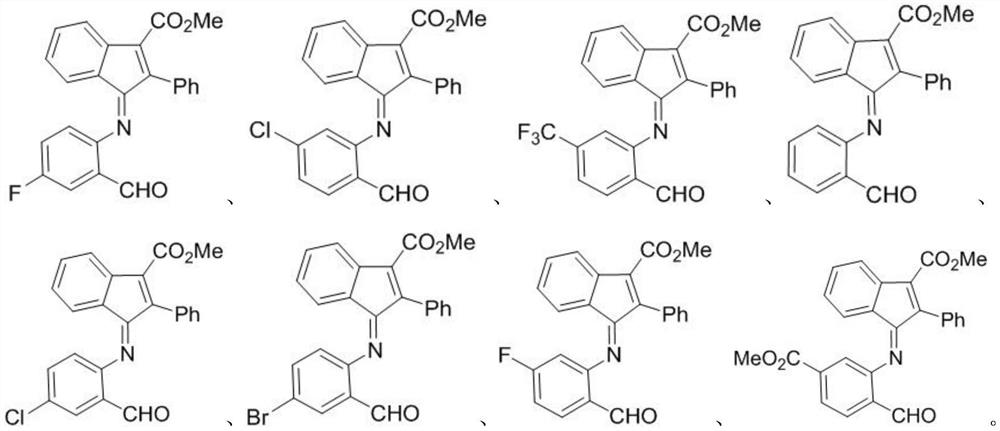

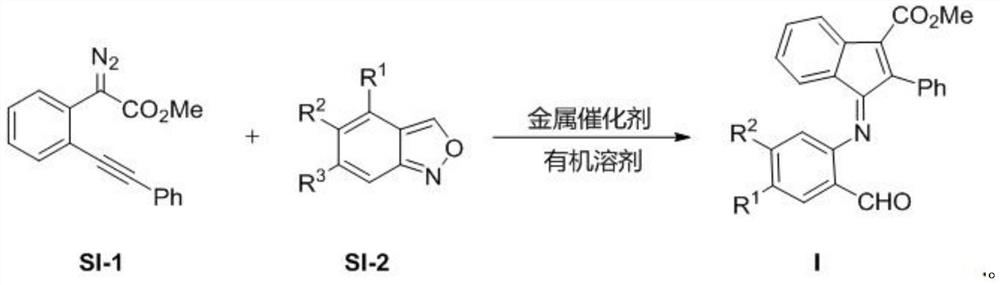

A kind of indanone imine derivative and its preparation method and application

ActiveCN113292448BNovel structureImprove anti-tumor effectOrganic active ingredientsAntineoplastic agentsMethyl palmoxirateChemistry

The present invention belongs to the technical field of medicinal chemistry, and specifically relates to an indenone imine derivative and its preparation method and application. The structure of the indenone imine derivative is shown in the general formula (I), wherein the R 1 selected from hydrogen, fluorine, chlorine, bromine; R 2 Selected from hydrogen, fluorine, chlorine, trifluoromethyl, and methoxycarbonyl; the derivative has a novel structure and has good antitumor effects, especially for colorectal adenocarcinoma cells, osteosarcoma cells, and breast cancer cells Inhibition of anti-tumor effect has great application value, and it is expected to be prepared as anti-tumor drug, especially anti-colorectal cancer cell, osteosarcoma cell and breast cancer cell drug; meanwhile, the indenone imine The preparation method of the derivative has fewer reaction steps, simple and safe operation, low cost, less waste generation, and has the advantages of high atom economy and high yield.

Owner:SUN YAT SEN UNIV

Indanone imine derivatives as well as preparation method and application thereof

ActiveCN113292448ANovel structureImprove anti-tumor effectOrganic active ingredientsAntineoplastic agentsPharmaceutical drugPerylene derivatives

The invention belongs to the technical field of medicinal chemistry, and particularly relates to indanone imine derivatives and a preparation method and application thereof. The structures of the indanone imine derivatives are as shown in a general formula (I) which is described in the specification. In the general formula (I), R1 is selected from hydrogen, fluorine, chlorine and bromine; and R2 is selected from hydrogen, fluorine, chlorine, a trifluoromethyl group and a methoxycarbonyl group. The derivatives are novel in structure, have very good anti-tumor effects, particularly show a very good inhibition effect on colorectal adenocarcinoma cells, osteosarcoma cells and breast cancer cells, have a very great application value in the aspect of the anti-tumor effect, and are expected to be made into anti-tumor drugs, especially drugs for resisting colorectal cancer cells, osteosarcoma cells and breast cancer cells; and meanwhile, the preparation method of the indanone imine derivatives has the advantages of few reaction steps, simplicity and safety in operation, low cost, less generated waste, high atom economy and high yield.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com