Method for removing methyl blue dye in wastewater

A methylene blue and dye technology, which is applied in the field of printing and dyeing sewage treatment, can solve the problems of incomplete contact, low adsorption capacity, insoluble in water, etc., and achieve the effects of reducing subsequent treatment steps, increasing effective contact, and excellent adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

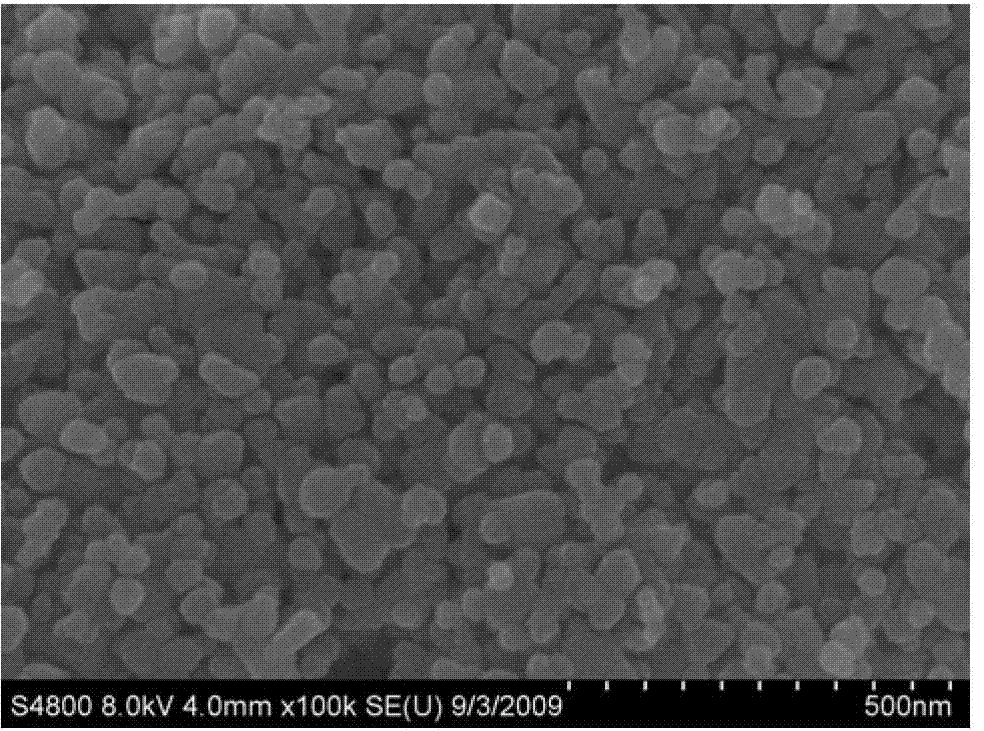

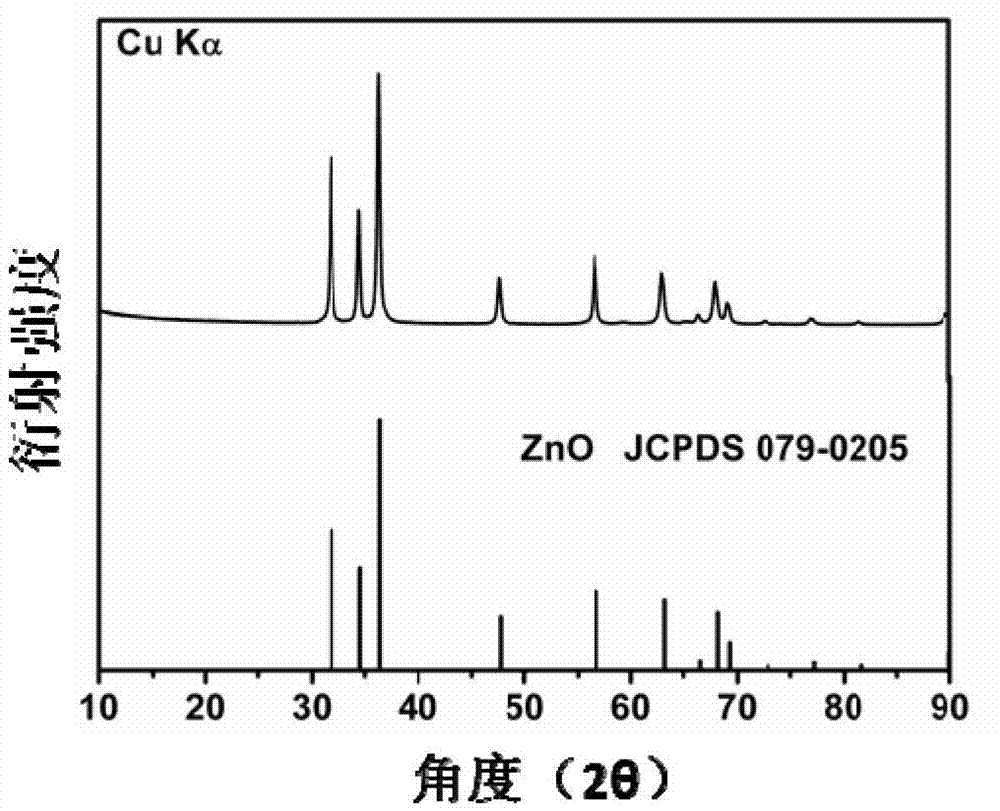

[0032] Add 0.03mol of zinc nitrate to 100mL of deionized water for dissolving, and add 0.005mol of polyvinyl alcohol 1800, fully stir for 30 minutes to make it disperse evenly, adjust the pH value with dilute ammonia water to obtain a solution with a pH value of 7; The solution was placed in water at 80°C to react zinc nitrate with polyvinyl alcohol 1800 for 4 hours, then vacuum-dried at 80°C for 8 hours, and then calcined at 800°C for 4 hours to obtain white pure zinc oxide. Microscope picture as figure 1 shown, from figure 1 Visible, the pure zinc oxide that makes is the nano spherical particle that diameter is 20~50nm; The X-ray diffraction spectrogram of this pure zinc oxide nanoparticle is as follows figure 2 shown.

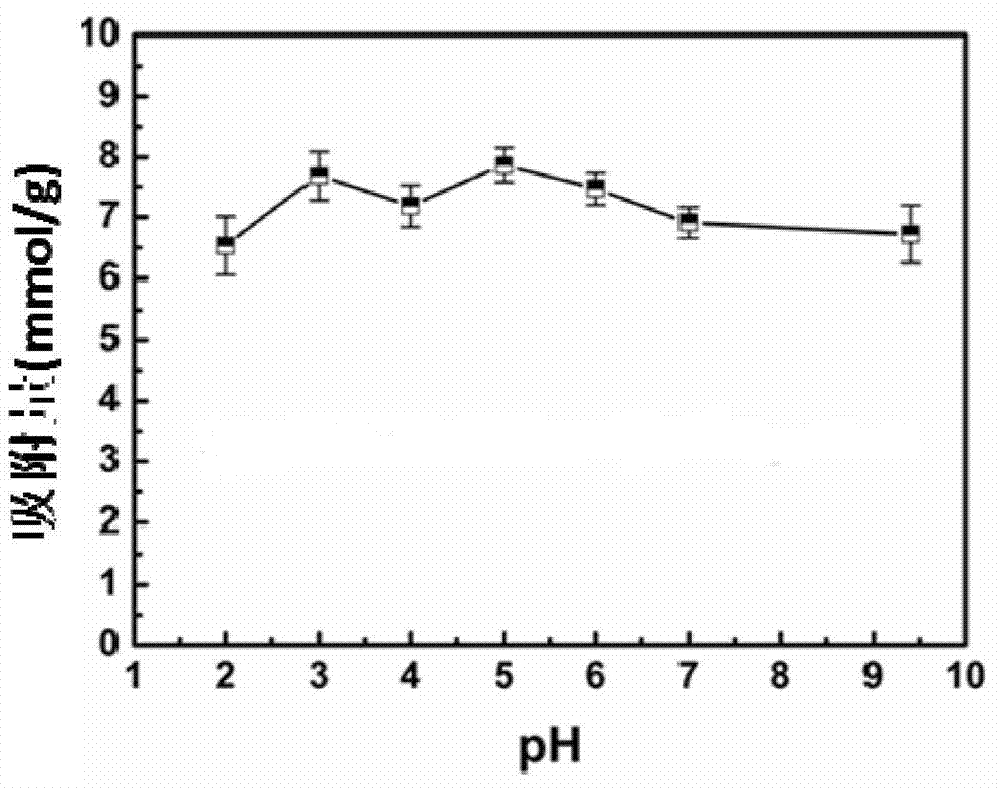

[0033] Prepare 50mL of 10mmol / L methylene blue aqueous solution in eight 100mL beakers, and use HCl and NaOH to adjust the pH of the solution so that the pH is 2, 3, 4, 4.5, 5, 6, 7, 9.5; Then add 0.05 g of the pure zinc oxide nanoparticles prepared in t...

Embodiment 2

[0035] Add 10 mol of zinc nitrate and 0.1 mol of aluminum nitrate into 1L of deionized water to dissolve, add 5 mol of polyethylene glycol 2000, stir well for 1 hour to disperse evenly, and obtain a solution; uniformly dissolve 20 mol of ammonium bicarbonate in the above solution , reacted at 20°C for 24 hours, dried the reaction product in vacuum at 70°C for 12 hours, and then calcined at 700°C for 2 hours to obtain a white zinc oxide-based material with a molar content of dopant aluminum of 1%. Its scanning electron microscope image is Figure 4 and Figure 5 shown, from Figure 4 and Figure 5 It can be seen that the prepared aluminum-doped zinc oxide-based material is a microtube composed of nanoparticles with a diameter of 20-30nm, the diameter of the microtube is 50-1000nm, and the length is 3-15μm. The X-ray diffraction spectrum of the microtube-based material is as follows Figure 6 shown.

[0036]Prepare 50mL of 2mmol / L methylene blue aqueous solution in five 100...

Embodiment 3

[0038] Add 10 mol of zinc nitrate and 1 mol of titanium nitrate into 1L of deionized water to dissolve, and add 2 mol of polyethylene glycol 2000, stir well for 1 hour to disperse evenly, and obtain a solution; add 1 mol / L sodium hydroxide solution dropwise evenly The above solution was reacted at 40°C for 5 hours, the reaction product was vacuum-dried at 40°C for 8 hours, and then calcined at 800°C for 6 hours to obtain a white zinc oxide-based material doped with 10% molar content of titanium.

[0039] Prepare 50mL of methylene blue aqueous solution in seven 100mL beakers with concentrations of 3mmol / L, 4mmol / L, 5mmol / L, 6mmol / L, 10mmol / L, 15mmol / L, 20mmol / L. Then 0.05 g of the titanium-doped zinc oxide-based material prepared in this example was added into these 7 beakers respectively. Magnetic stirring reaction at 50°C for 1 hour; after 30 minutes of natural sedimentation, take 5mL solution from the beaker with a syringe, filter out impurities with a 0.45 microliter needle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com