Fenton reaction system and method for treating organic pollutants in waste water by Fenton reaction system

A reaction system and reaction technology, applied in the field of organic pollutants, can solve the problems of reducing organic matter removal efficiency, increasing energy consumption, increasing operation complexity, etc., to reduce the burden of subsequent neutralization treatment, reduce operating costs, and save power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings:

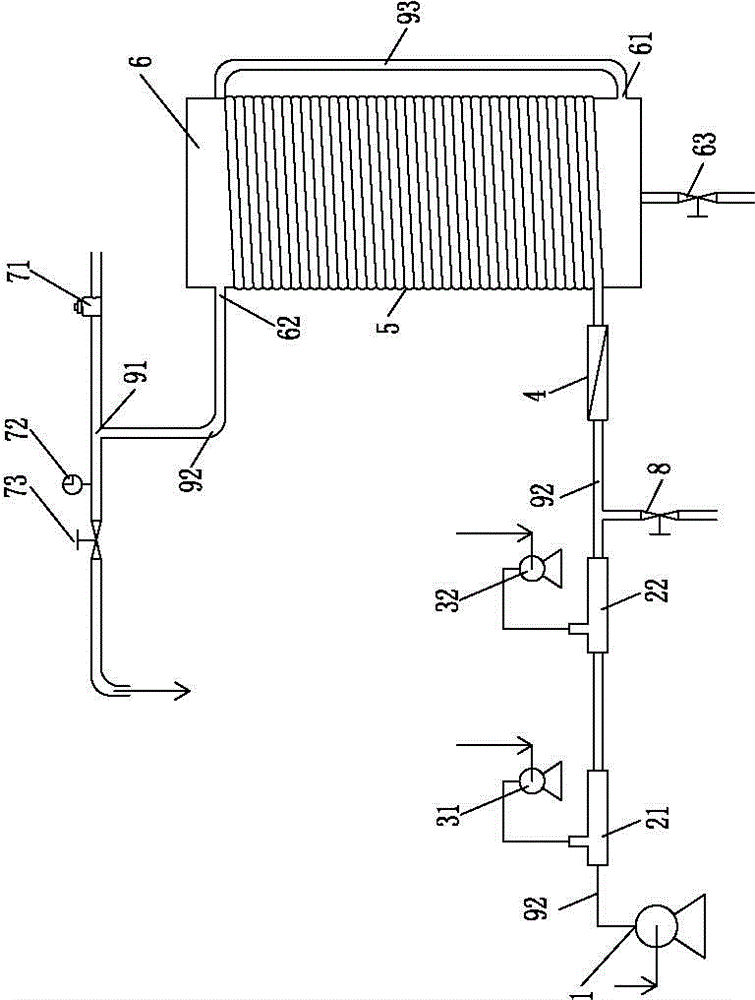

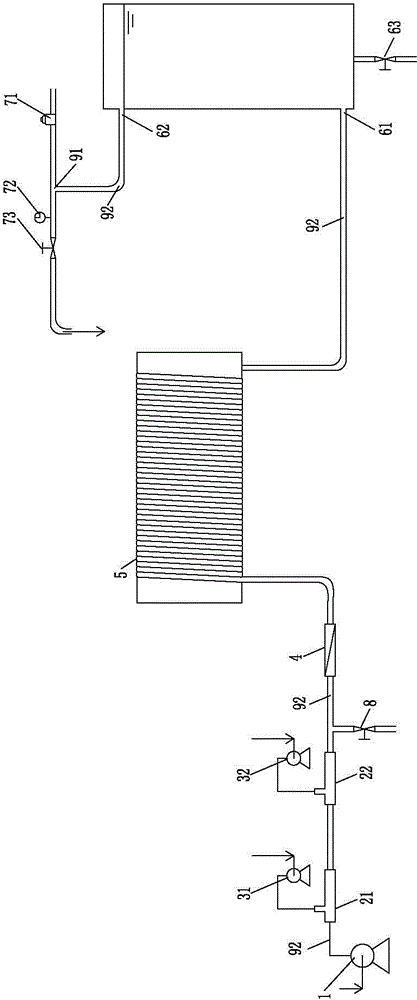

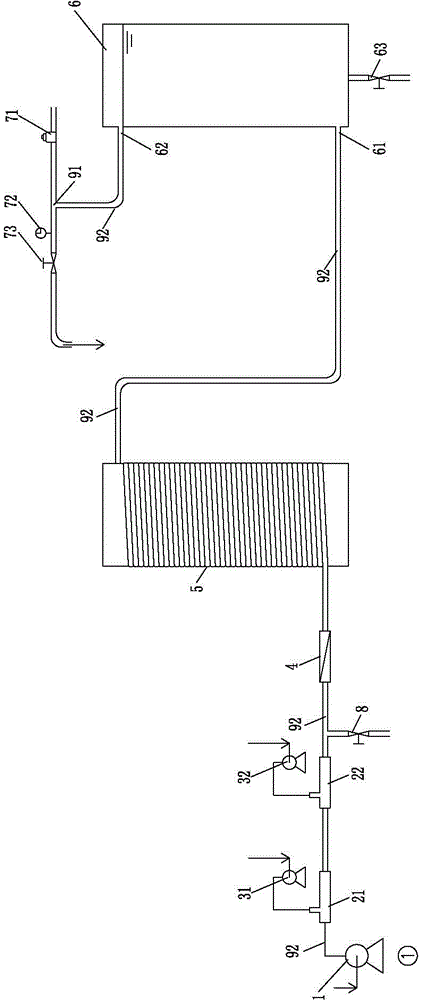

[0044] figure 1 , Figure 5 , Image 6 A first embodiment of the Fenton reaction system of the present invention is shown.

[0045] see figure 1 As shown, the Fenton reaction system includes the waste water whose pH is adjusted to 3 is pumped into the pipeline 92 through the feed pump 1, and the two first jets 21 and the second jets 22 connected in series with the pipeline 92 are respectively connected with After mixing the oxidant H2O2 30% in the Fenton reagent and the catalyst FeSO4 120g / L solution in the Fenton reagent inputted by the first metering pump 31 and the second metering pump 32, it flows into the check valve 4 through the check valve 4 in the pipeline. Connected vertical spiral coils 5 for mixing reactions, see Figure 5 , Image 6 As shown, the spiral coil 5 is wound on the outer wall of the reaction tank 6 from bottom to top, the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com