Solar heat reflective heat insulating and preserving foaming ceramic material and manufacturing method thereof

A foamed ceramic, thermal insulation technology, applied in the production of ceramic materials, ceramic products, clay products, etc., can solve the problems of bonding strength, poor weather resistance, cumbersome processes, etc., and achieves low production costs, scientific technology, and preparation methods. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

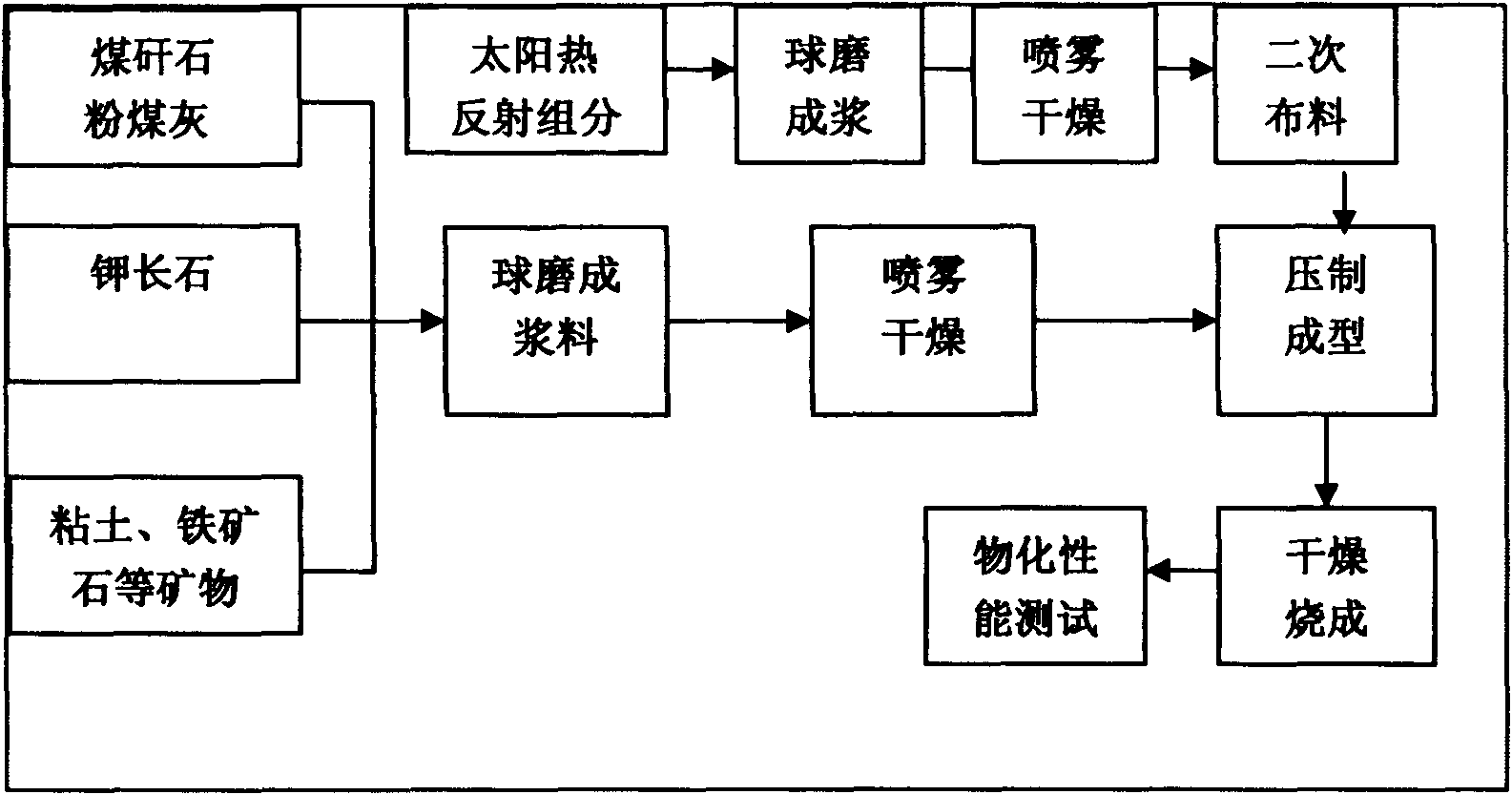

Method used

Image

Examples

Embodiment 1

[0044]Prepare foamed ceramic matrix materials according to mass percentage: 40wt% coal gangue, 40wt% feldspar, 10wt% clay, and 10wt% hematite. After the raw ore is crushed, add it to a ball mill, add water and mix it for wet grinding, and then spray dry the slurry The foamed ceramic matrix granulate is obtained and stored for future use.

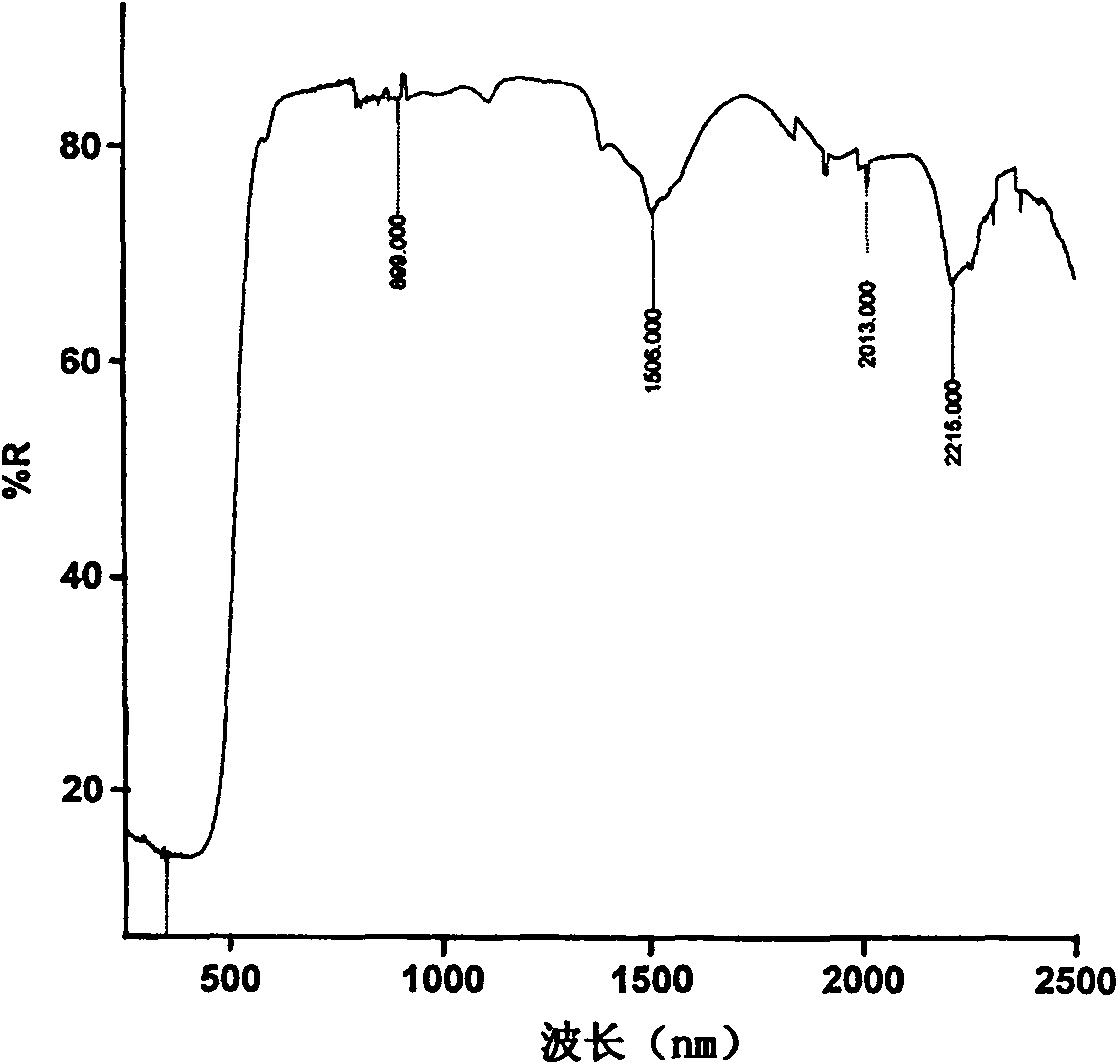

[0045] Prepare the solar heat reflection layer material by mass percentage: coal gangue 17wt%, feldspar 30wt%, clay 20wt%, ilmenite ore 10wt%, low-temperature porcelain stone 5wt%, zirconium silicate 15wt%, inorganic synthetic pigment (silicic acid The zirconium-based synthetic yellow pigment is Huachang company product SR25301) 3wt%. After the raw ore material is crushed, it is added to a ball mill, mixed with water and wet-milled, and then the slurry is spray-dried to obtain a solar heat reflection layer granulated material, which is stored for future use.

[0046] The granulated material of the above-mentioned foamed ceramic matrix is d...

Embodiment 2

[0049] Prepare the foamed ceramic matrix material according to mass percentage: 20% of coal gangue, 40wt% of feldspar, 20wt% of low-temperature porcelain stone, 15wt% of clay, and 5wt% of hematite. After crushing the raw ore material, add it to a ball mill, add water and mix it for wet grinding, Then the slurry is spray-dried to obtain a foamed ceramic matrix granulate, which is stored for future use.

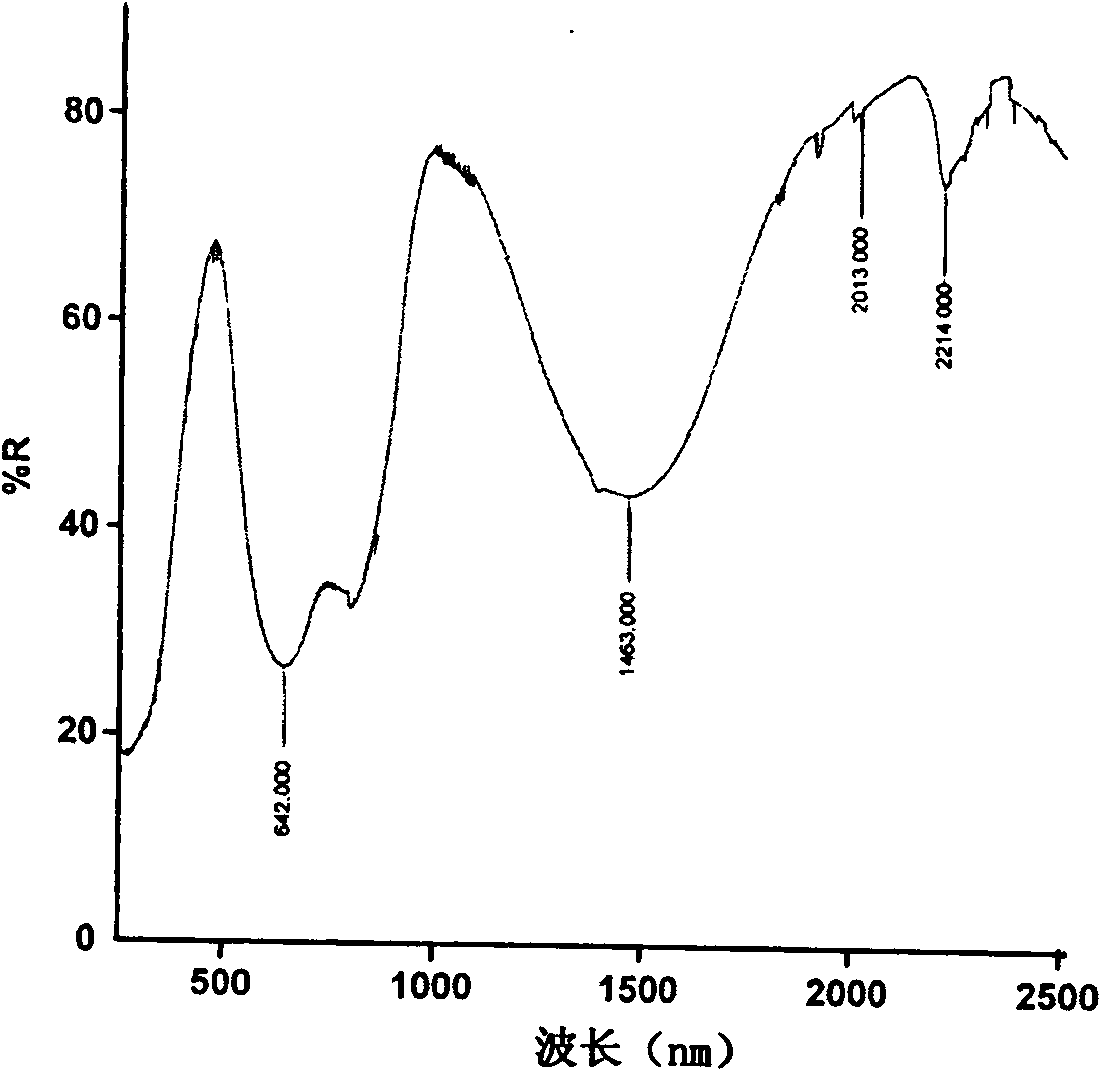

[0050] Prepare the solar heat reflective layer material by mass percentage: feldspar 35wt%, clay 25wt%, ilmenite ore 10wt%, low-temperature porcelain stone 15wt%, zirconium silicate 15wt%, inorganic synthetic pigment (zirconium silicate base synthetic blue Pigment, product of Huachang Company SR22508) 2wt%, raw ore material is crushed and added to a ball mill, mixed with water and wet-milled, then the slurry is spray-dried to obtain a solar heat reflective layer granulated material, which is stored for future use.

[0051] The granulated material of the above-mentioned foamed c...

Embodiment 3

[0054] Prepare the foamed ceramic matrix material according to mass percentage: 20%wt% of coal gangue, 25%wt% of fly ash, 30wt% of feldspar, 20wt% of clay, and 3wt% of hematite ore. Add the raw ore material to the ball mill after crushing, add water mixing and wet grinding, and then spray drying the slurry to obtain a foamed ceramic matrix granulate, which is stored for future use.

[0055] Prepare solar heat reflection layer material by mass percentage: feldspar 27wt%, clay 25wt%, ilmenite ore 10wt%, coal gangue 15wt%, low-temperature porcelain stone 15wt%, zirconium silicate 8wt%, inorganic synthetic pigment (silicic acid Zirconium-based synthetic red material, Huachang company product SR23560) 1wt%, the raw ore material is crushed and put into a ball mill, mixed with water and wet-milled, and then the slurry is spray-dried to obtain a solar heat reflection layer granulated material, which is stored for future use.

[0056] The granulated material of the above-mentioned foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com