Method of preparing monobutyl tin trichloride and dibutyl tin dichloride from low purity tributyl tin chloride

A low-purity tributyltin chloride, monobutyltin trichloride technology, applied in the direction of tin organic compounds, etc., can solve the problems of serious environmental pollution, difficult to handle, lack of tributyltin chloride and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

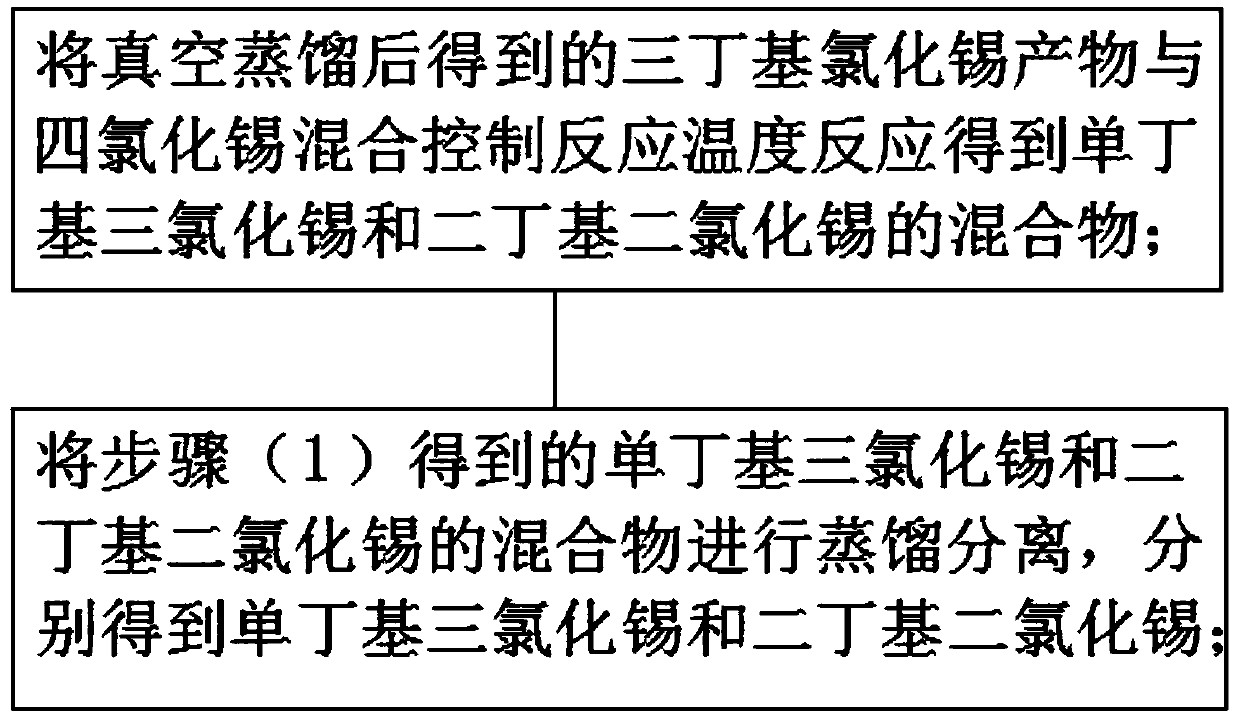

[0011] see figure 1 , this embodiment discloses a method for preparing monobutyltin trichloride and dibutyltin dichloride from low-purity tributyltin chloride, comprising the following steps: (1) making the purity lower than 95% The tributyl tin chloride product and tin tetrachloride mixed control reaction temperature reaction obtains the mixture of monobutyl tin trichloride and dibutyl tin dichloride; (2) monobutyl tin chloride that step (1) obtains The mixture of tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com