A method for enriching 1-deoxynojirimycin in mulberry leaves and the obtained ultrafine powder

A technology of deoxynojirimycin and ultra-fine powder, which is applied in the field of food biology, can solve the problems of side effects and single diabetes, and achieve the effects of low side effects, high preservation rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

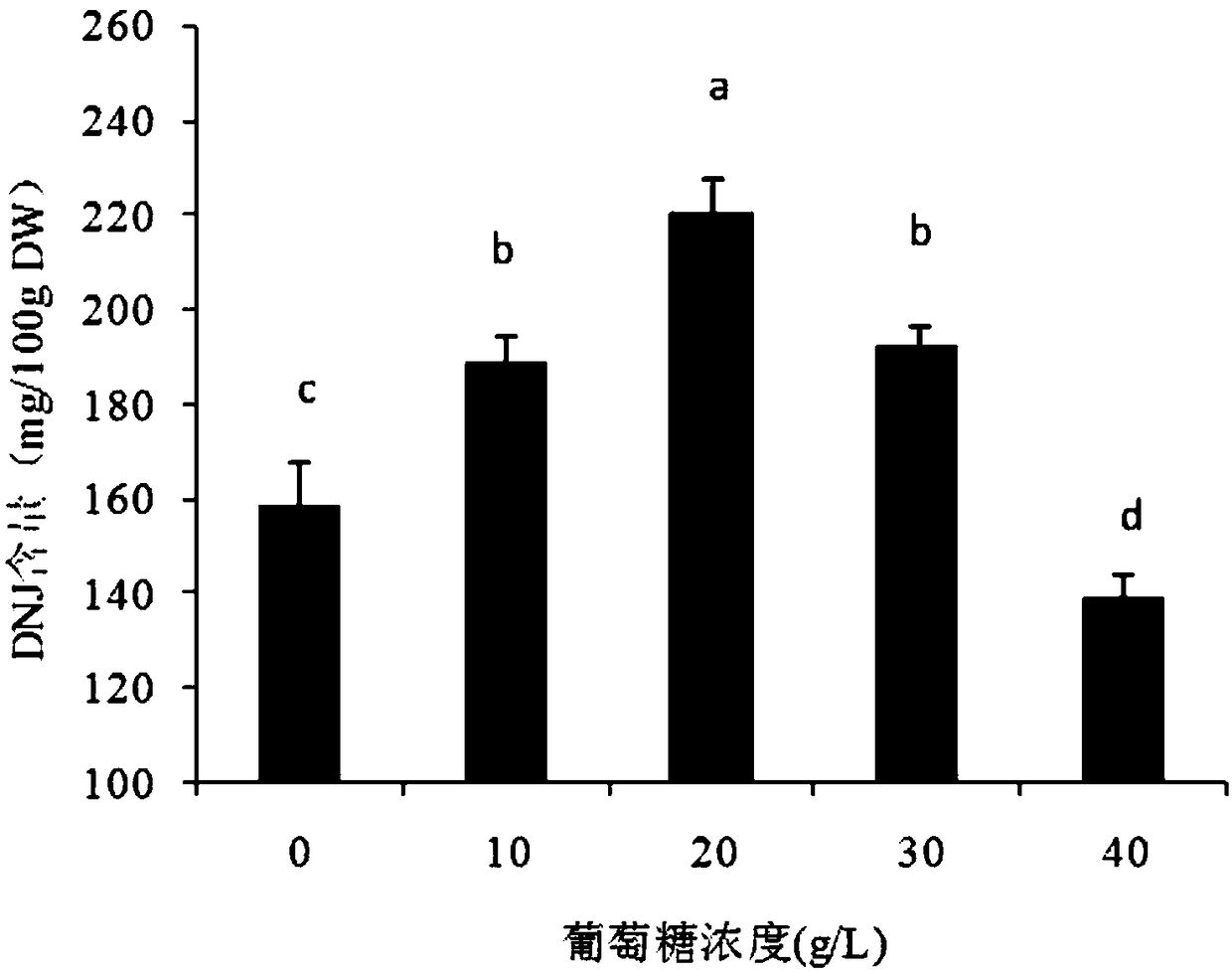

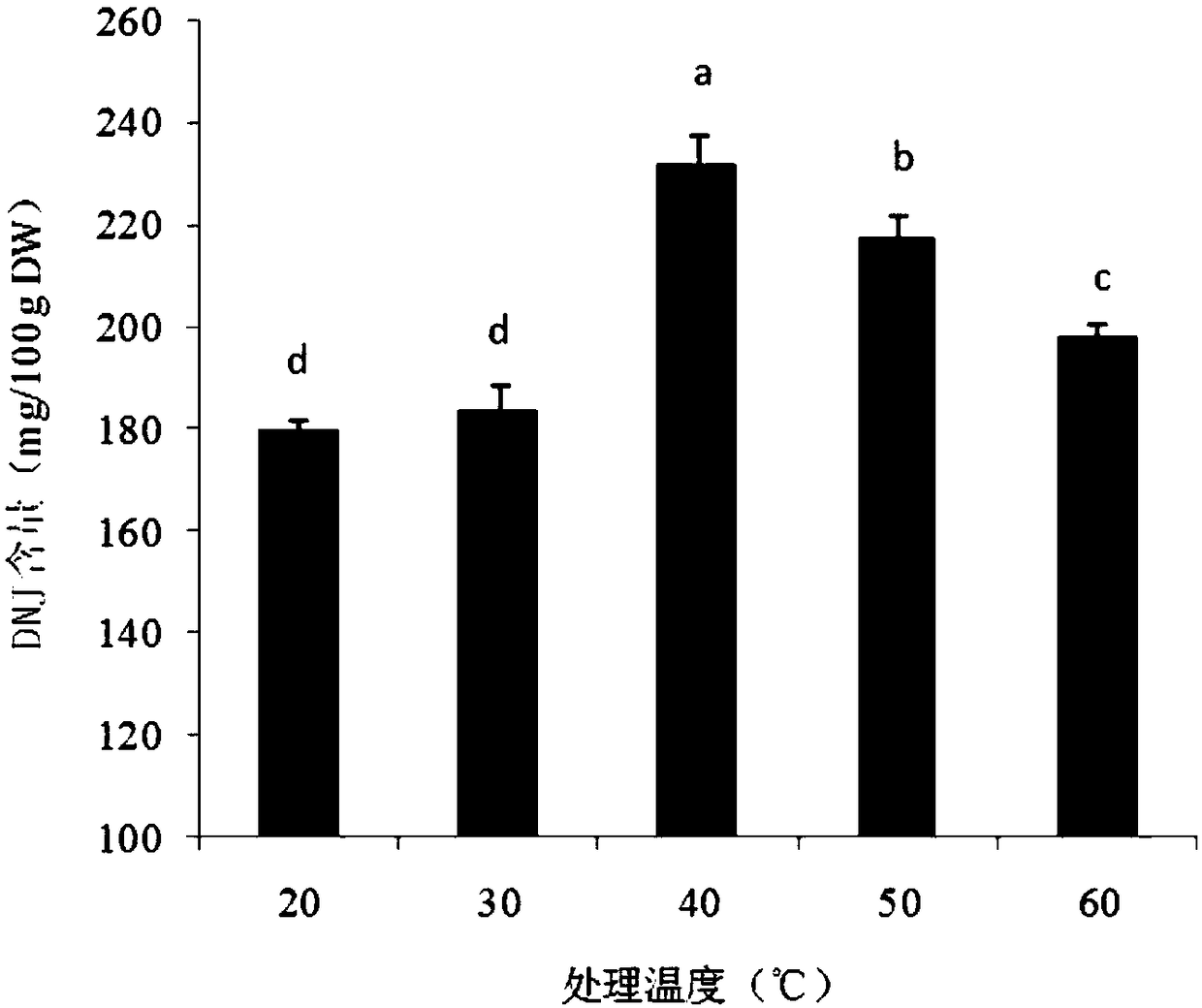

Embodiment 1

[0031] Select fresh and complete tender mulberry leaves, remove the stalks and clean them, cut them into 8 pieces, soak them in 20g / L glucose solution at 40°C, take them out after 3 hours, drain the sugar solution, and then dry them in a hot air drying oven at 60°C until The water content is less than 5%, and the plant tissue grinder is used for coarse grinding to more than 80 mesh, and the vibration ball mill is used for 11 hours to grind to an average particle size of 5 μm, and dried in an oven at 50°C to reduce the water content to less than 5%. After the dried product is cooled to room temperature, it is packed with nitrogen.

Embodiment 2

[0033] Select fresh and complete mulberry leaves, remove the stalks and clean them, cut them into 6 pieces, soak them in 15g / L glucose solution, and dry them in a hot air drying oven at 65°C until the water content is below 5% after 4 hours at 35°C , use a plant tissue pulverizer to coarsely pulverize to more than 80 mesh, use a vibrating ball mill to pulverize for 9 hours to an average particle size of 8 μm, and then dry in an oven at 50°C to reduce the moisture content to below 5%. After the dried product is cooled to room temperature, it is packed with nitrogen.

Embodiment 3

[0035] Wash and dry the fresh and complete tender mulberry leaves and cut them into several flake fragments, immerse the mulberry leaf fragments in the glucose solution for a certain period of time, take out the mulberry leaf fragments and dry them until the water content of the mulberry leaves is below 5%, and then coarsely crush them to More than 80 meshes, pulverized by a vibrating ball mill or ultrafine pulverizer, dried to reduce the water content to below 5% to obtain mulberry leaf ultrafine powder enriched in 1-deoxynojirimycin.

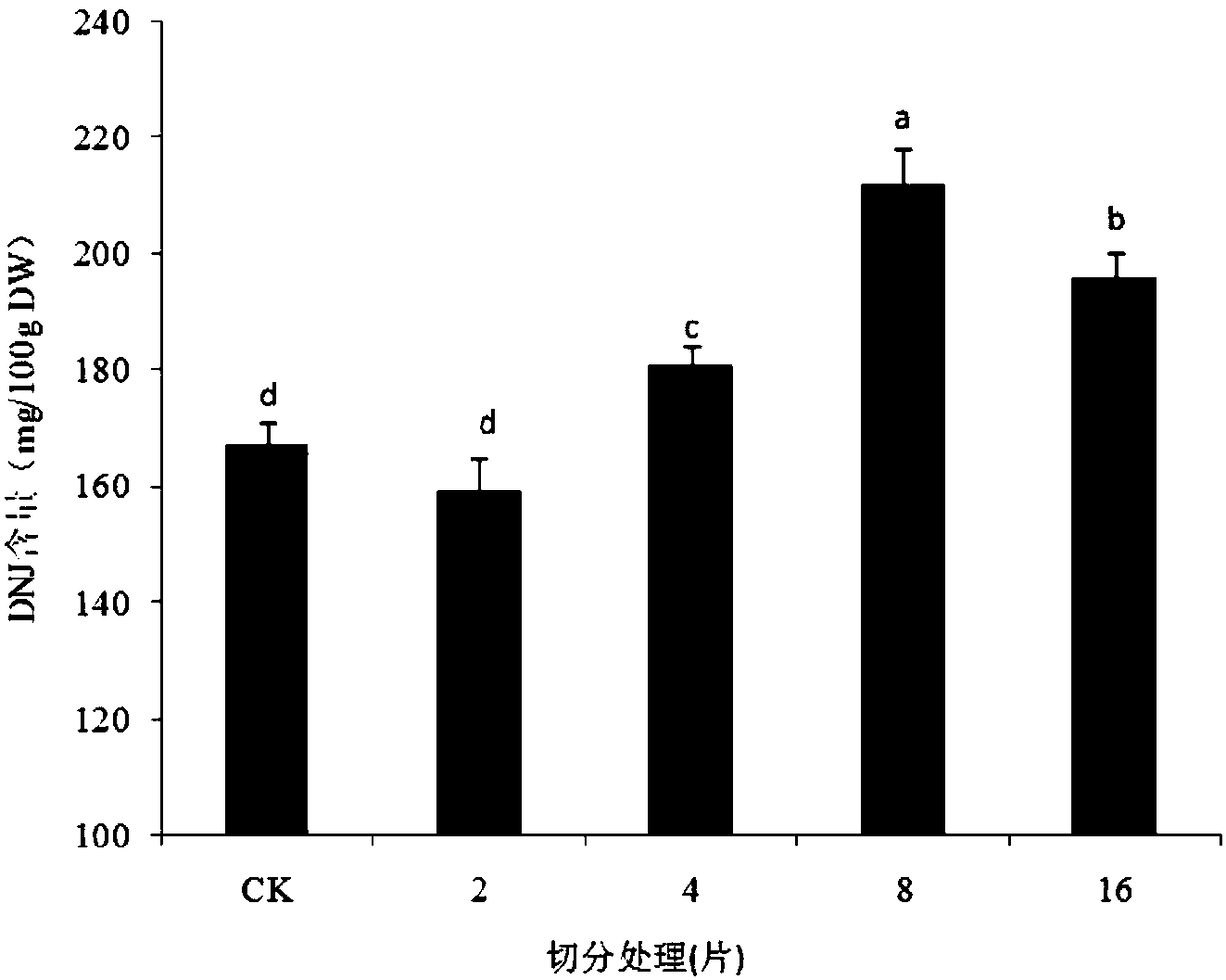

[0036] 1. The influence of mechanical cutting ( figure 1 )

[0037] Select mulberry leaves with similar leaf size, divide them into 5 parts, each 100g, cut them into 2 pieces, 4 pieces, 8 pieces, and 16 pieces respectively. Take the whole leaves as the control, soak them in 20g·L -1 In the glucose solution, let it stand for 2h, while the temperature is controlled at 30°C. It was found that the content of DNJ reached the highest when the cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com