Five-axis numerical control machine tool open-angle and close-angle area machining capacity detecting test pieces and method

A technology of numerical control machine tools and processing capabilities, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as complex configuration, various processing features, and complicated factors affecting processing accuracy, and achieve simple surface characteristics, Simple configuration, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

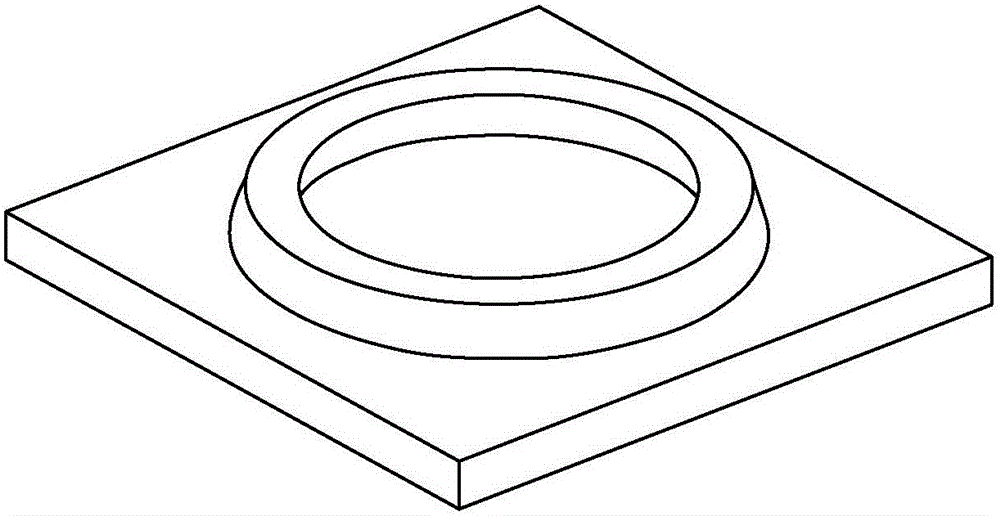

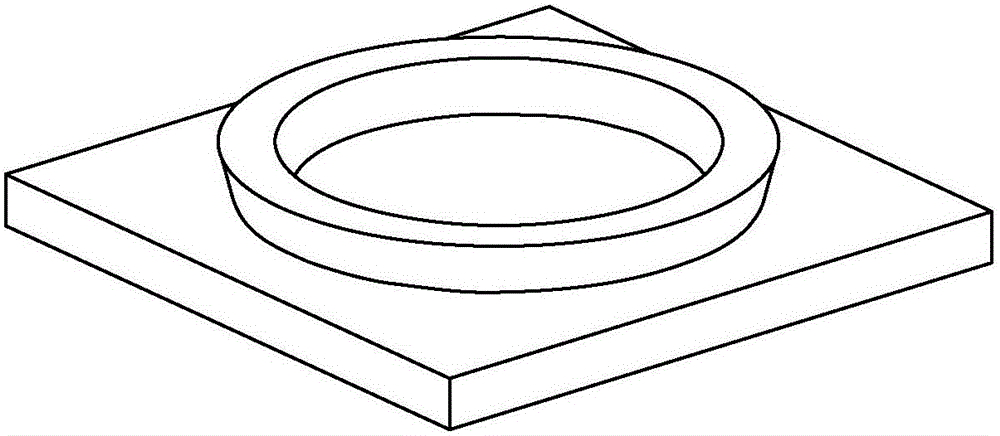

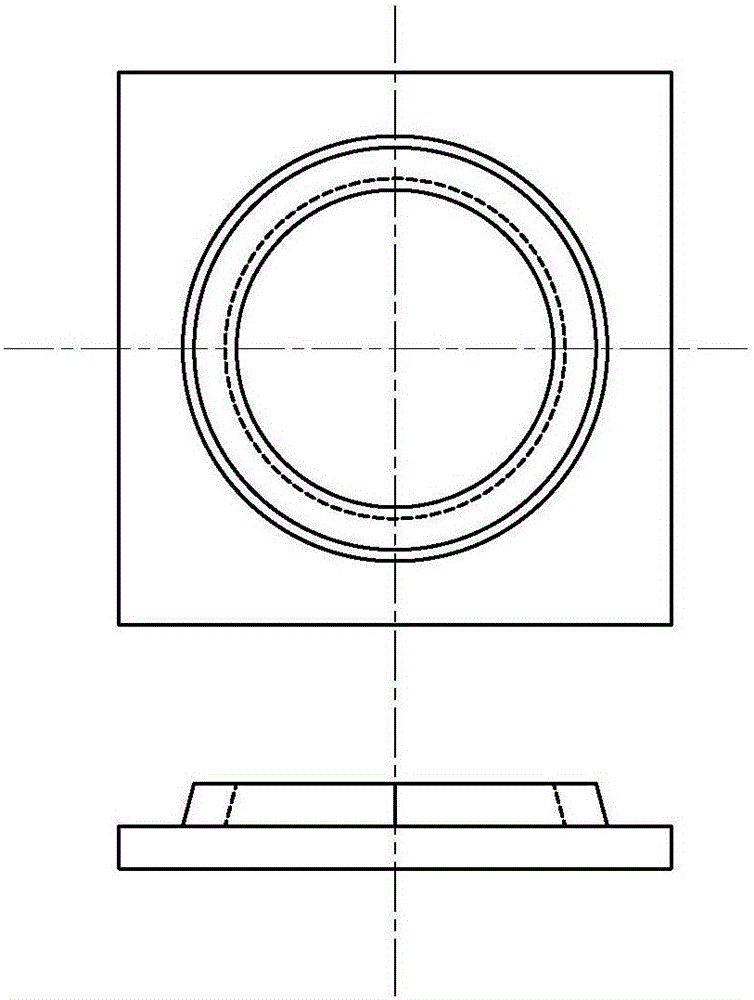

[0035] Such as Figure 1 to Figure 4 As shown, a five-axis numerically controlled machine tool of the present invention has an opening and closing angle area processing capability detection test piece. Since it is impossible to ensure that other characteristics are consistent except for the opening and closing angle characteristics in one test piece, the present invention designs two kinds of test pieces: Test piece A and test piece B, both test piece A and test piece B include a rectangular base and a conical ring located at the center of the upper surface of the rectangular base, the center of the conical ring and the center of the rectangular base are in the horizontal direction The projection coincides, and the longitudinal section of the conical ring passing through the center of the conical ring and perpendicular to the section of the rectangul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com