A kind of crucible automatic storage cabinet with separate access and crucible automatic storage method

An automatic access and separate technology, applied in tool storage devices, manufacturing tools, etc., can solve problems such as affecting work efficiency, delaying tests, and large space occupied by crucible storage cabinets, so as to reduce work complexity and reduce crucible removal. The effect of improving efficiency and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

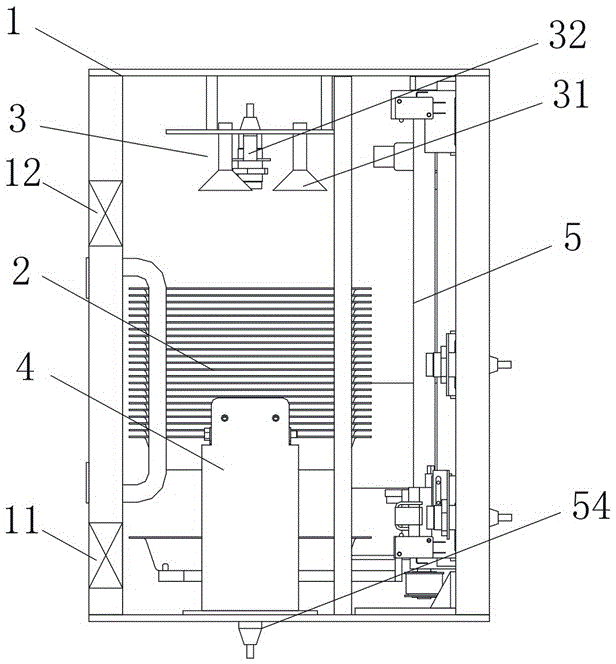

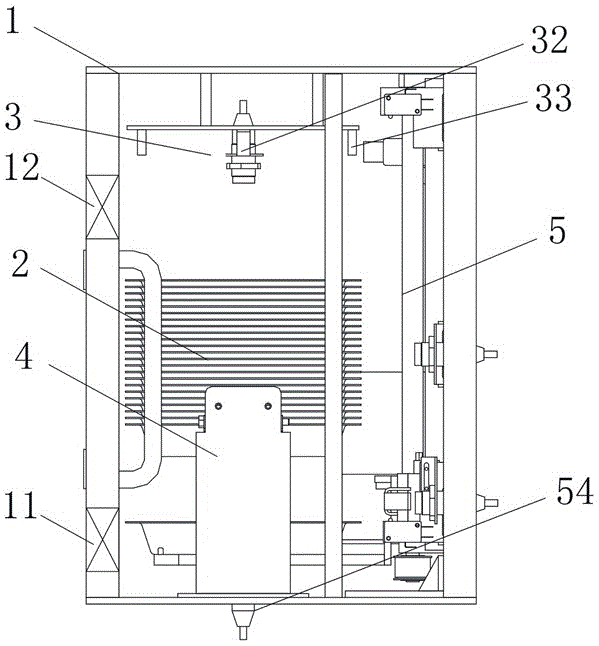

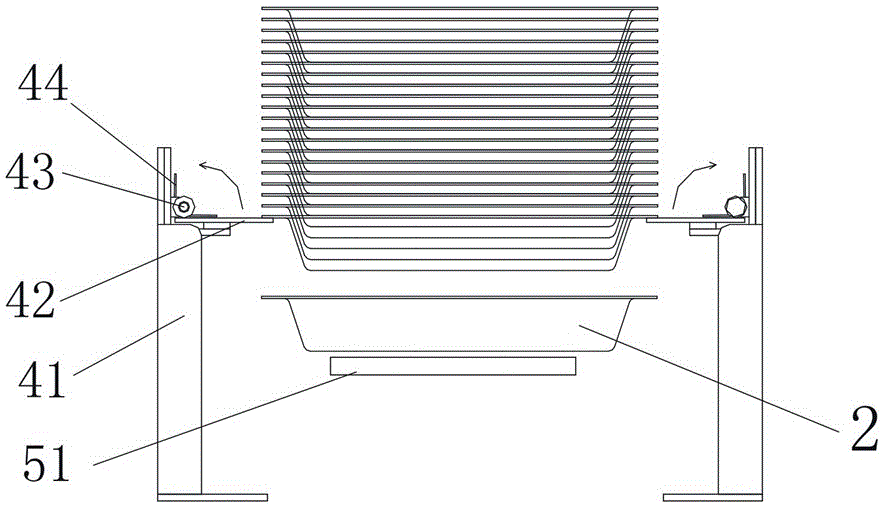

[0041] like Figure 1 to Figure 5As shown, the present invention provides an automatic crucible storage and retrieval cabinet with separate access, including a cabinet body 1, a crucible storage port 11 is opened at the lower part of the side wall of the cabinet body 1, and a crucible take-out port 12 is opened at the upper part of the side wall. The crucible storage port 11 enters and exits to complete the storage of the crucible 2 , and enters and exits from the crucible take-out port 12 to complete the taking out of the crucible 2 . The cabinet 1 is provided with an adsorption assembly 3 for adsorbing the crucible 2, a crucible hanging plate assembly 4 for storing the crucible 2, and a lifting assembly 5 for driving the crucible 2 to move up and down in sequence from top to bottom. Multiple crucibles 2 are stacked in sequence. and mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com