Automatic strap threading system

A technology of automatic tape threading and tape guiding, applied in the direction of strapping materials and parts of strapping machinery, can solve the problems of high labor intensity and low degree of automation, and achieve the effect of improving work efficiency, reducing packaging costs and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

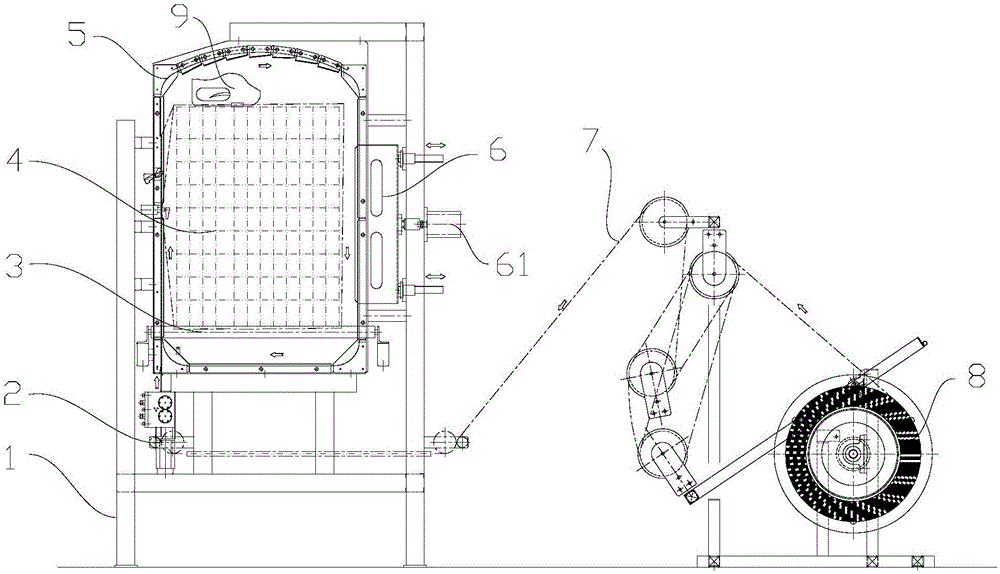

[0026] see figure 1 , taking brick stacking as an example of bundling and packing of goods 4, the stacked bricks are transported on the conveyor roller 3 for packing, and the automatic belt threading system applied on the conveyor includes frame 1, belt feeding assembly 2. Conveying roller 3, belt guide groove 5, clapping plate 6, belt reel 8 and hand tool 9.

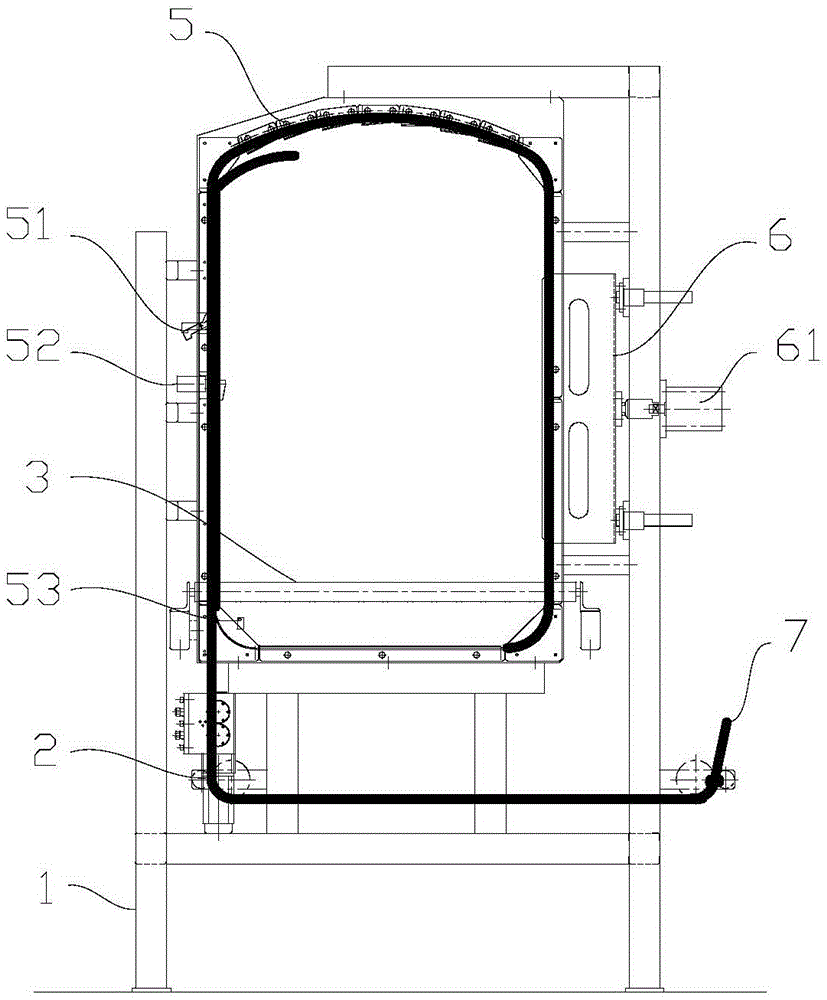

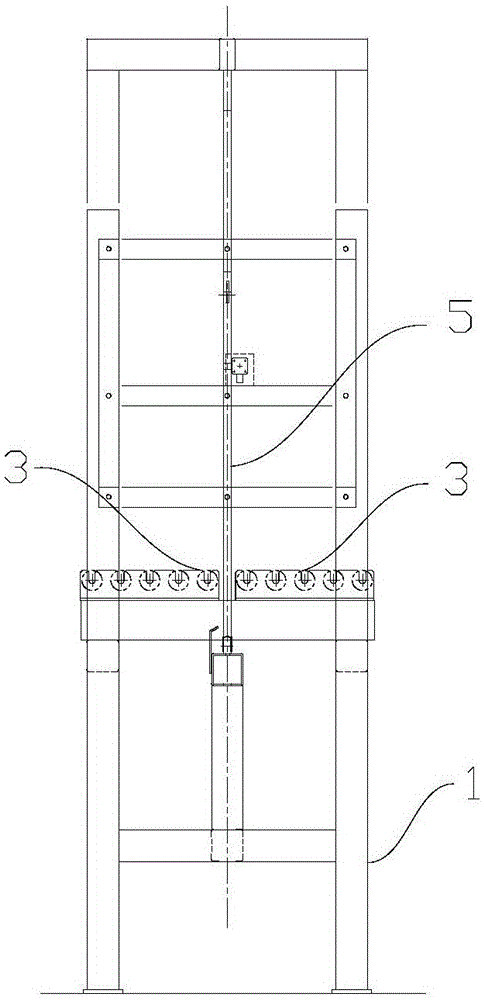

[0027] join figure 2 and image 3 , the guide belt groove 5 is horizontally arranged between the adjacent conveying rollers 3 of the conveyor, and forms a closed loop, which is set on the conveying channel of the conveying rollers, and its size can allow the goods 4 conveyed on the conveying rollers to pass smoothly. In order to facilitate the smooth passage of bricks and save the waste of packaging belts, both sides of the closed loop of the belt guide groove 5 are vertically arranged close to the sides of the brick stacking, and the top and bottom are respectively connected by arc transitions, and the bottom is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com