Ceramic edging wheel for glass edging machine and preparation method thereof

A technology of edge pulling wheel and edge pulling machine is applied in the field of ceramic edge pulling wheel for glass edge pulling machine and its preparation, which can solve the problems of low temperature, large temperature difference of tin bath working conditions, linear speed error of edge pulling wheel, etc. Improve high temperature performance, stable line speed, and be beneficial to production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

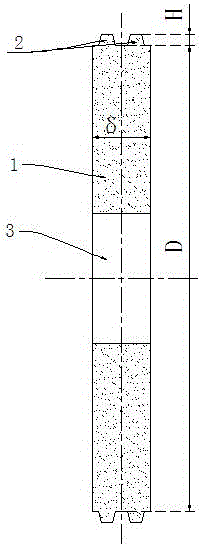

Image

Examples

Embodiment 1

[0021] A preparation method of a ceramic edge wheel for a glass edge puller, comprising the following steps: step 1, by weight percentage, weighing 30% silicon powder, 20% boron powder, 27% particle size of 200 mesh silicon carbide, 15% A ceramic raw material composed of silicon carbide with a particle size of 74-100 microns, 8% silicon carbide with a particle size of 100-120 microns, and 1% sodium carboxymethyl cellulose, and a weight of 12% of the total weight of ceramic raw materials. Ionized water, mix 74~120 micron silicon carbide and half weight sodium carboxymethyl cellulose and stir for 10 minutes, add 200 mesh silicon carbide and continue stirring for 5 minutes, then add boron powder, silicon powder and the remaining carboxymethyl cellulose Sodium, after stirring for 15 minutes, inject it into a mold matching the shape and size of the edge wheel.

[0022] Since both silicon carbide and silicon are barren materials, they have high density and poor suspension, and are p...

Embodiment 2

[0029] A preparation method of a ceramic edge wheel for a glass edge puller, comprising the following steps: Step 1, by weight percentage, weighing 25% silicon powder, 10% boron powder, 30% particle size of 200 mesh silicon carbide, 22% Silicon carbide with a particle size of 74 to 100 microns, 13% silicon carbide with a particle size of 100 to 120 microns, and 0.8% sodium carboxymethyl cellulose are used as ceramic raw materials. Ionized water, mix 74~120 micron silicon carbide and half weight sodium carboxymethyl cellulose and stir for 8 minutes, add 200 mesh silicon carbide and continue stirring for 5 minutes, then add boron powder, silicon powder and the remaining carboxymethyl cellulose Sodium, after stirring for 20 minutes, pour it into a mold that matches the shape and size of the edge wheel, demould after molding, trim the green body, and dry the green body at 110°C until the water content drops below 0.5%, and then put the green body according to the conventional metho...

Embodiment 3

[0033] A preparation method of a ceramic edge wheel for a glass edge pulling machine, comprising the following steps: Step 1, by weight percentage, weighing 28% silicon powder, 15% boron powder, 29% particle size of 200 mesh silicon carbide, 18% Silicon carbide with a particle size of 74 to 100 microns, 10% silicon carbide with a particle size of 100 to 120 microns, and 0.5% sodium carboxymethyl cellulose are ceramic raw materials, and the weight is 11% of the total weight of ceramic raw materials. Ionized water, mix 74~120 micron silicon carbide and half weight sodium carboxymethyl cellulose and stir for 5 minutes, add 200 mesh silicon carbide and continue stirring for 5 minutes, then add boron powder, silicon powder and the remaining carboxymethyl cellulose Sodium, after stirring for 18 minutes, pour it into a mold that matches the shape and size of the edge wheel, demould after molding, trim the green body, and dry the green body at 100°C until the water content drops below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com