A harmless treatment method for waste electronic lead-containing glass

A technology of harmless treatment and glass, applied in the direction of improving process efficiency, etc., can solve problems such as lead pollution of leaded glass, achieve the effects of short smelting cycle, realization of harmless treatment, and flexible technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

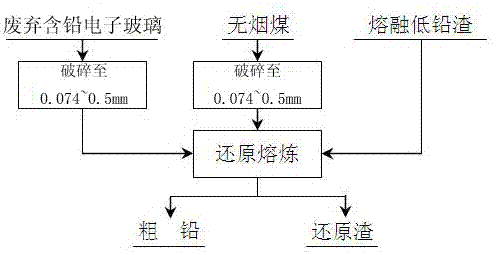

Image

Examples

Embodiment 1

[0031] Break the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, wherein the low-lead slag is 200g, the waste electronic lead-containing glass is 20g, and the amount of anthracite is waste 1.5 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1200°C for 1.0h to obtain crude lead and reducing slag.

[0032] After analysis, the crude lead content is 98.26%, the lead content in the reduction slag is 1.47%, and the recovery rate of lead is 92.71%.

Embodiment 2

[0034] Crush the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, in which the low-lead slag is 200g, the waste electronic lead-containing glass is 40g, and the amount of anthracite is waste 1.2 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1250°C for 0.8h to obtain crude lead and reducing slag.

[0035] After analysis, the crude lead content is 98.55%, the lead content in the reduction slag is 1.35%, and the recovery rate of lead is 93.33%.

Embodiment 3

[0037] Break the waste electronic lead-containing glass and anthracite to 0.074~0.5mm respectively, mix them evenly, and add them to the molten low-lead slag melt, wherein the low-lead slag is 200g, the waste electronic lead-containing glass is 20g, and the amount of anthracite is waste 1.0 times the molar amount of lead oxide in electronic lead-containing glass; melting the mixed material at 1250°C for 0.5h to obtain crude lead and reducing slag.

[0038] After analysis, the crude lead content is 98.23%, the lead content in the reduction slag is 1.25%, and the recovery rate of lead is 94.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com