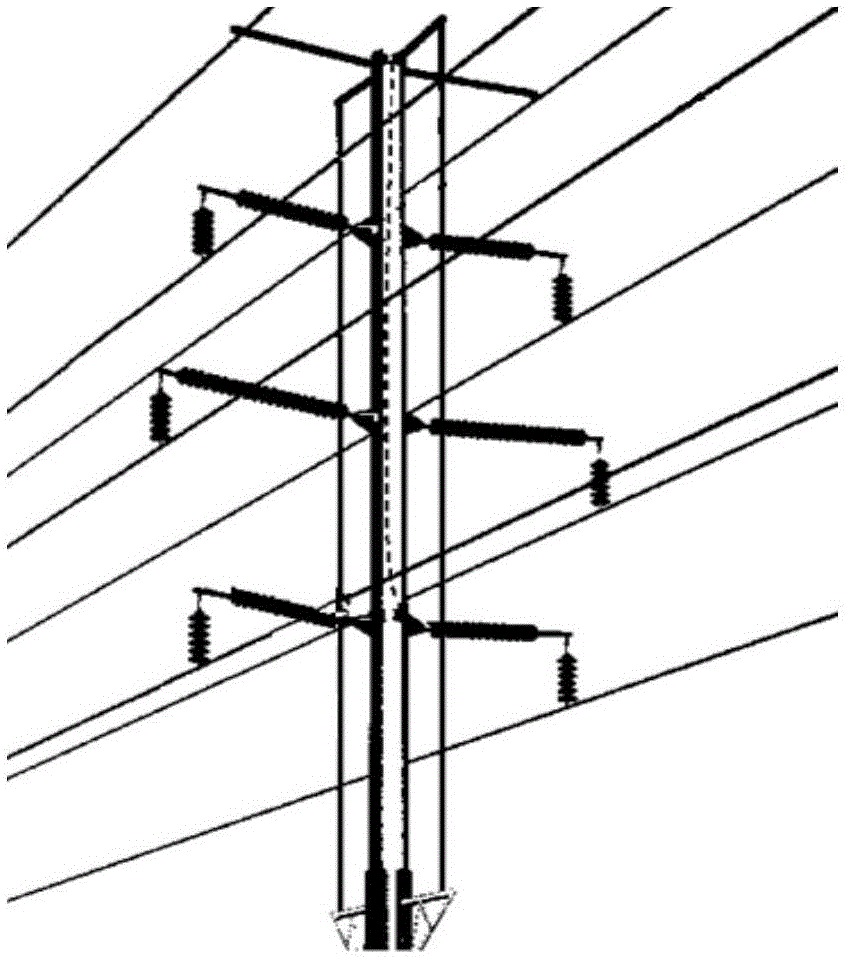

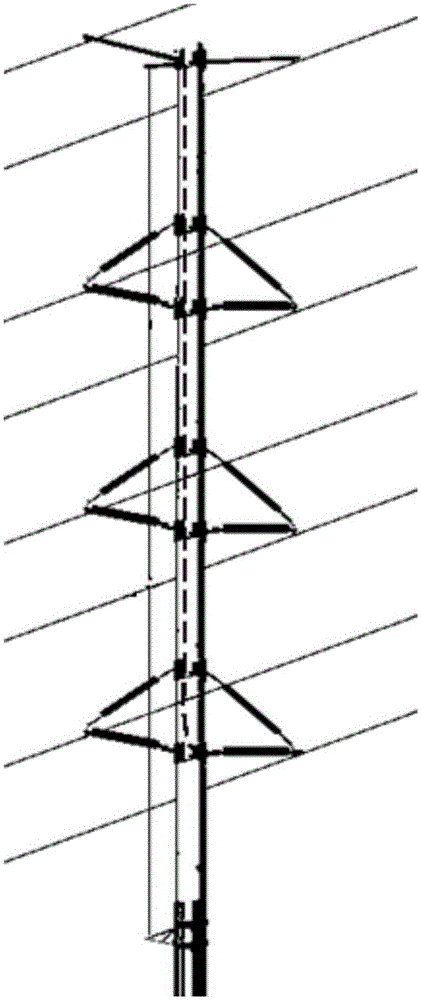

35kv double-circuit tubular composite rod tower

A composite material and double-circuit technology, applied in the field of poles and towers, can solve problems not mentioned above, achieve good versatility, eliminate the effects of damage caused by electrical insulation and structural strength, and simplify the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

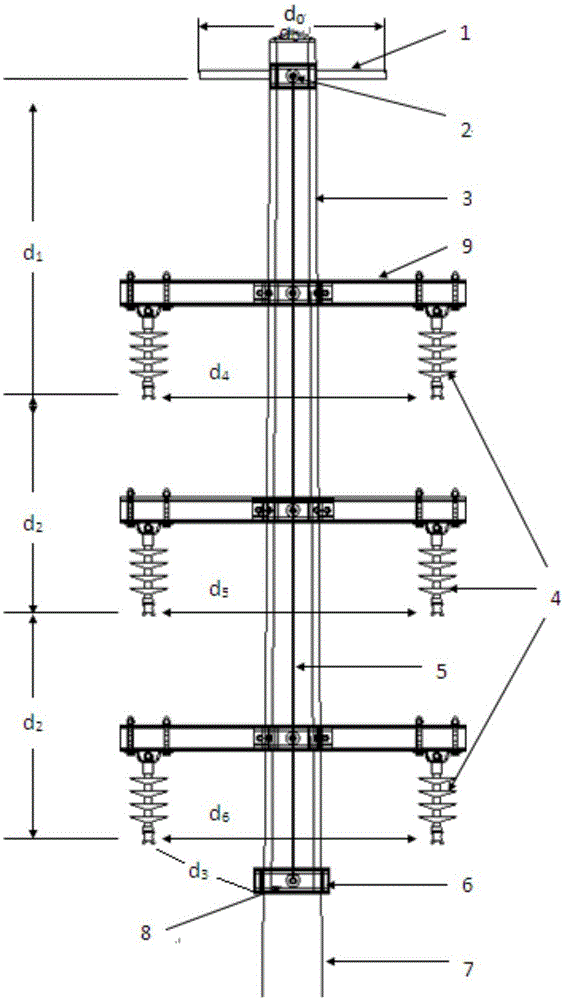

[0024] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0025] The double-circuit tubular composite pole tower applicable to 35kV overhead lines provided by the present invention is as follows: image 3 and Figure 4 As shown, it includes a metal shaft 7 fixedly connected in the vertical direction and a composite material insulating rod head 3 fixed on the upper end of the metal shaft 7, and the metal shaft 7 and the composite material insulating rod head 3 are connected by the composite material insulating rod head and the metal The shaft is fixedly connected with the hoop 6, and the composite material insulating rod head 3 is sequentially fixed with a ground wire crossarm 1 perpendicular to the composite material insulating rod head 3 and three square tubular composite material crossarms 9 from top to bottom. , the two ends of the ground wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com