Active eddy-current damping device and feeding system with same

A technology of eddy current damping and feeding system, which is applied in the field of active eddy current damping device and feeding system vibration control, which can solve the problems of service life, stability, reliability and limited application range of speed, so as to improve motion accuracy and stability , The effect of vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

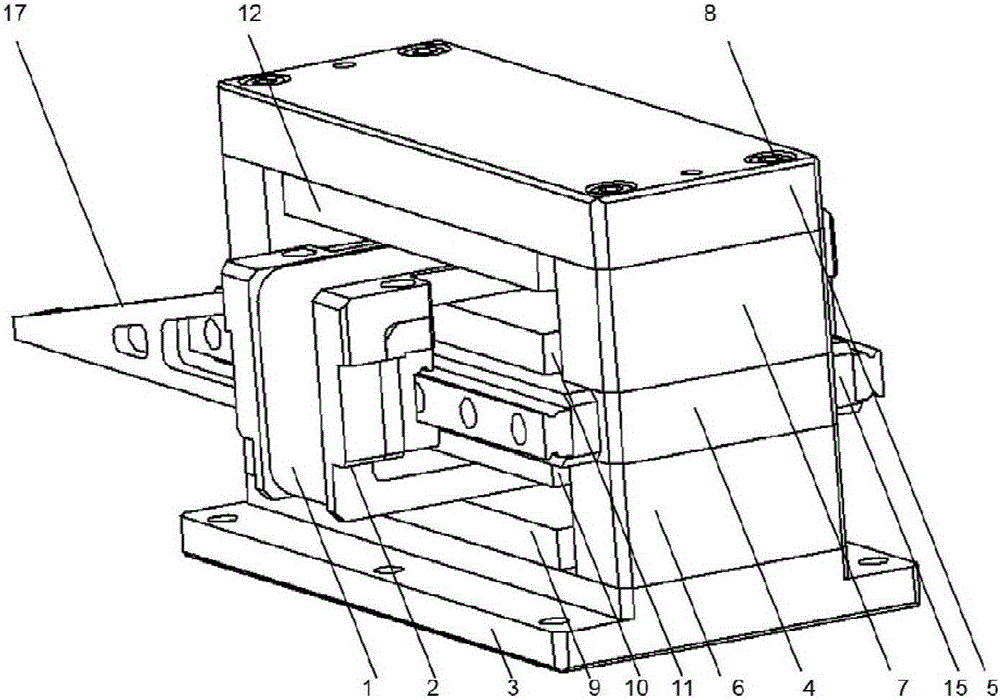

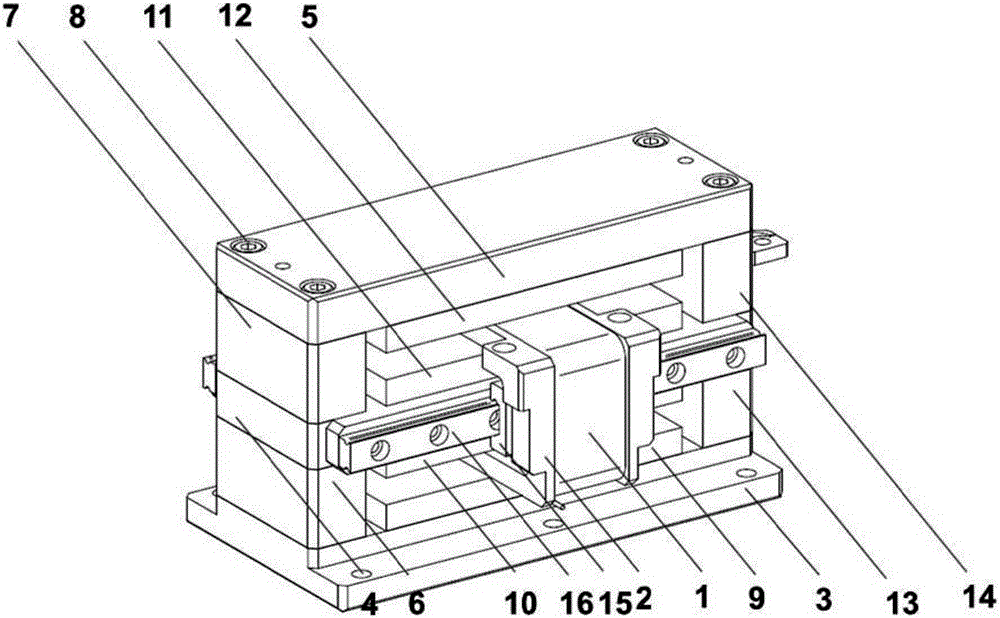

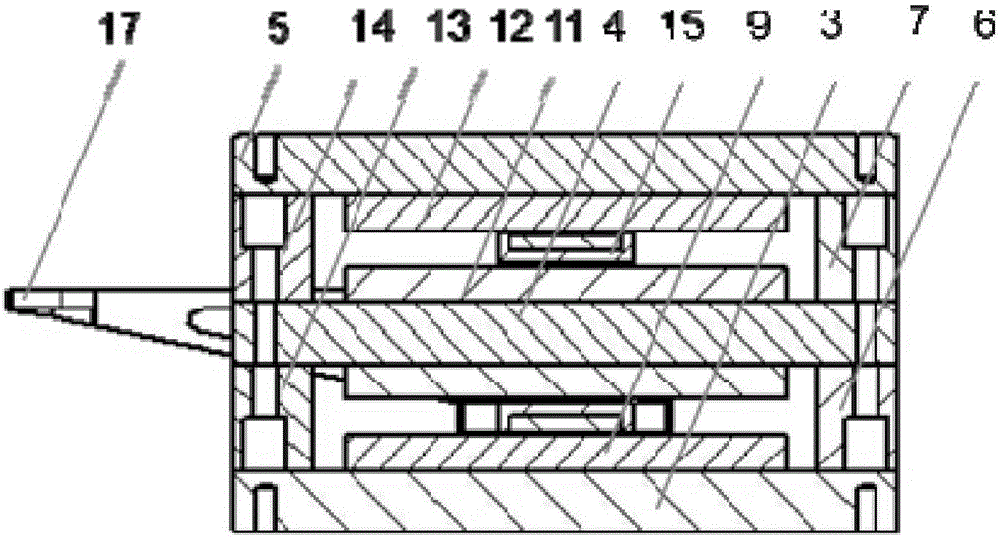

[0037] Such as figure 1 , 2 As shown, the active eddy current damping device of this embodiment consists of a coil 1, a bobbin 2, a base 3, a support body 4, a cover plate 5, a first conductor 9, a second conductor 10, a third conductor 11, and a fourth conductor 12 , a slider 15, a guide rail 16, a connecting plate 17 and a bracket. The support includes a support body right support 6, a cover plate right support 7, a support body left support 13, and a cover plate left support 14.

[0038] The coil 1 is installed on the bobbin 2 . The coil frame 2 is a hollow structure.

[0039] Such as figure 1 , 2 , 3, and 4, the base 3, the support body 4, and the cover plate 5 are arranged sequentially from bottom to top. The first conductor 9 is installed on the base 3 , the second conductor 10 is installed on the lower surface of the support body 4 , the third conductor 11 is installed on the upper surface of the support body 4 , and the fourth conductor 12 is installed on the low...

Embodiment 2

[0052] In this embodiment, the structure of the active eddy current damping device is exactly the same as that of the active eddy current damping device in Embodiment 1.

[0053] In this embodiment, the active eddy current damping device can be used in the feed system to suppress vibration during the motion of the feed system and improve motion accuracy and stability. The feeding system is exactly the same as that in Example 1.

[0054] Such as Image 6 As shown, the active eddy current damping device is represented by a reference number 22, and the active eddy current damping device is installed between the slide table 20 and the base 18 of the feed system, as Image 6 As shown, the guide rail 16 in the active eddy current damping device may not be installed. In the working state, the coil bobbin 2 of the eddy current damping device is fixedly connected to the slide table 20, and the slide table 20 makes a feed motion along the track 19, driving the coil 1 in the active edd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com