A feedwater regulation system for boilers in thermal power plants

A technology for regulating systems and thermal power plants, which is used in the control of water supply, liquid variable-capacity machinery, and preheating to achieve significant energy-saving effects, prolong service life, and reduce equipment failure rates and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0045] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

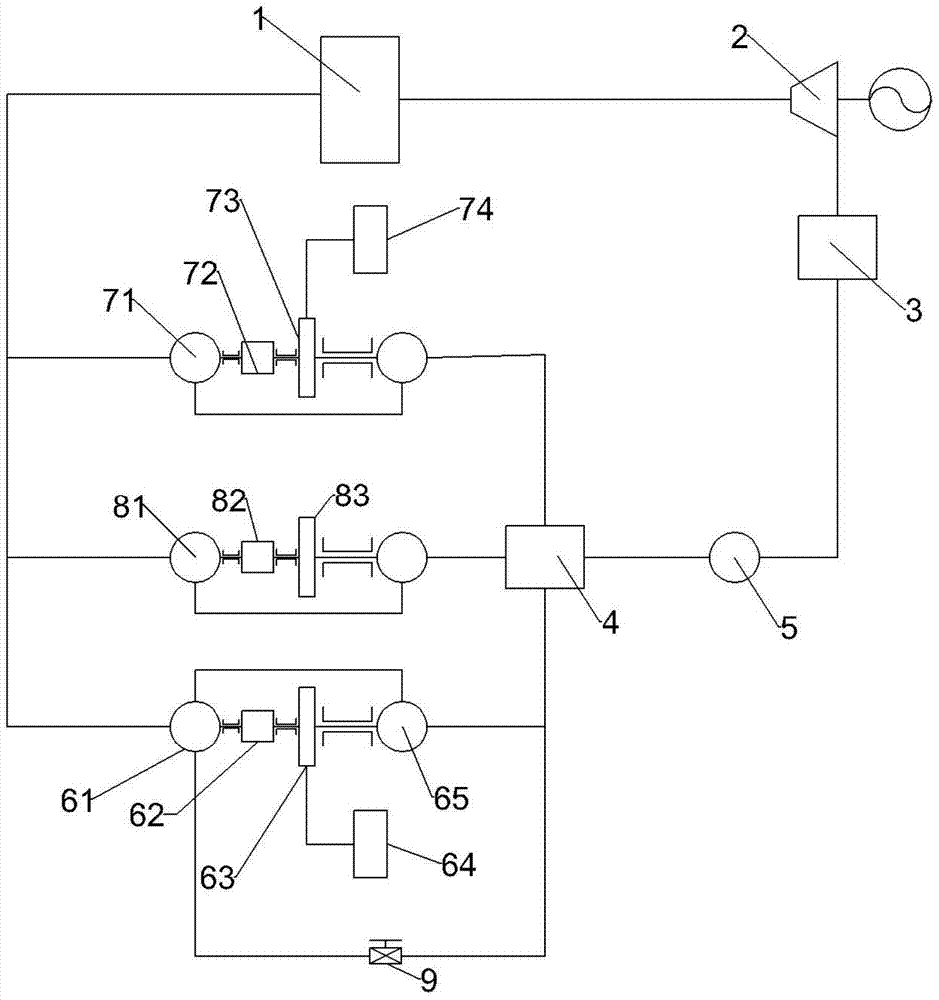

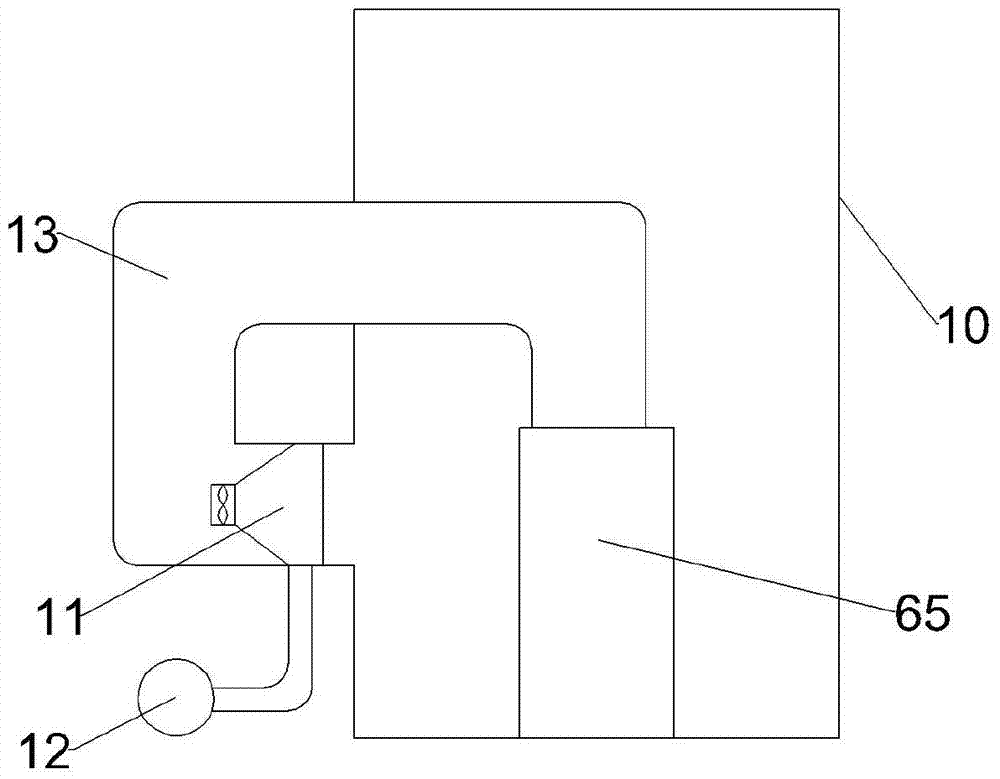

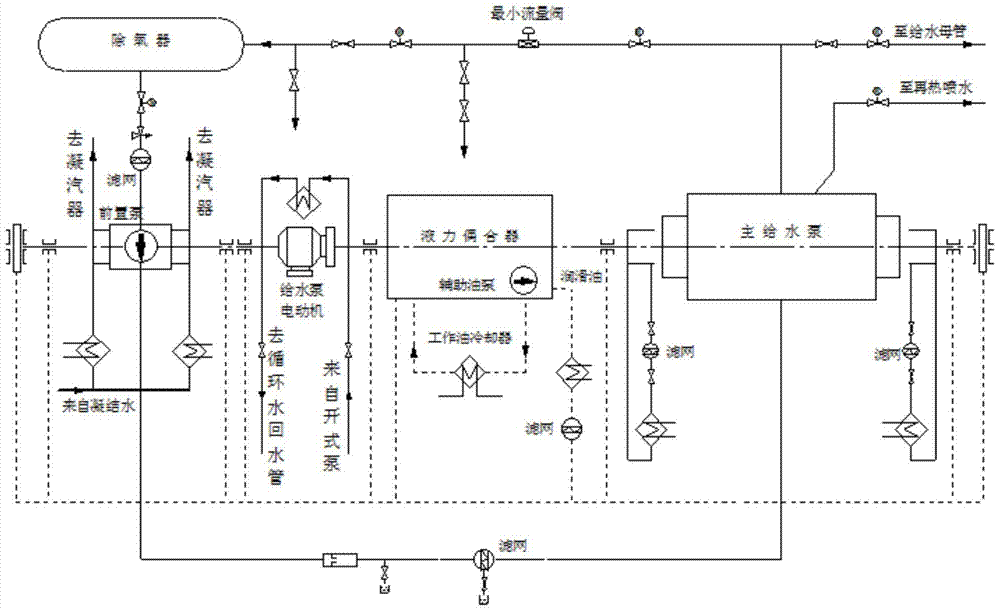

[0046] figure 1 An implementation form according to the present invention is shown, which includes:

[0047] The first feed water pump 61, the water outlet of which communicates with the water inlet of the boiler 1, is used to pump water into the boiler 1;

[0048] A first water pump motor 63, which is power-connected to the first feedwater pump 61 through a first hydraulic coupling 62, and is used to drive the first feedwater pump 61 to run;

[0049] The first frequency converter 64, which is arranged between the power supply and the first water pump motor 63, is used to chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com