Warning system for wheel disengagement of sintering circle-cooling machine

A technology of sintering ring cooler and ring cooler, which is applied in the directions of alarms, furnace types, instruments, etc., can solve problems such as trolley deformation, trolley wheel falling off, derailment, etc., and achieve the effect of avoiding further expansion of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

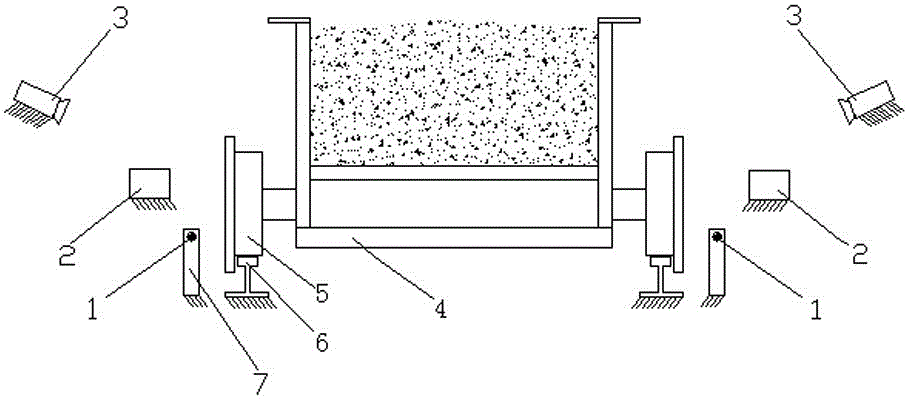

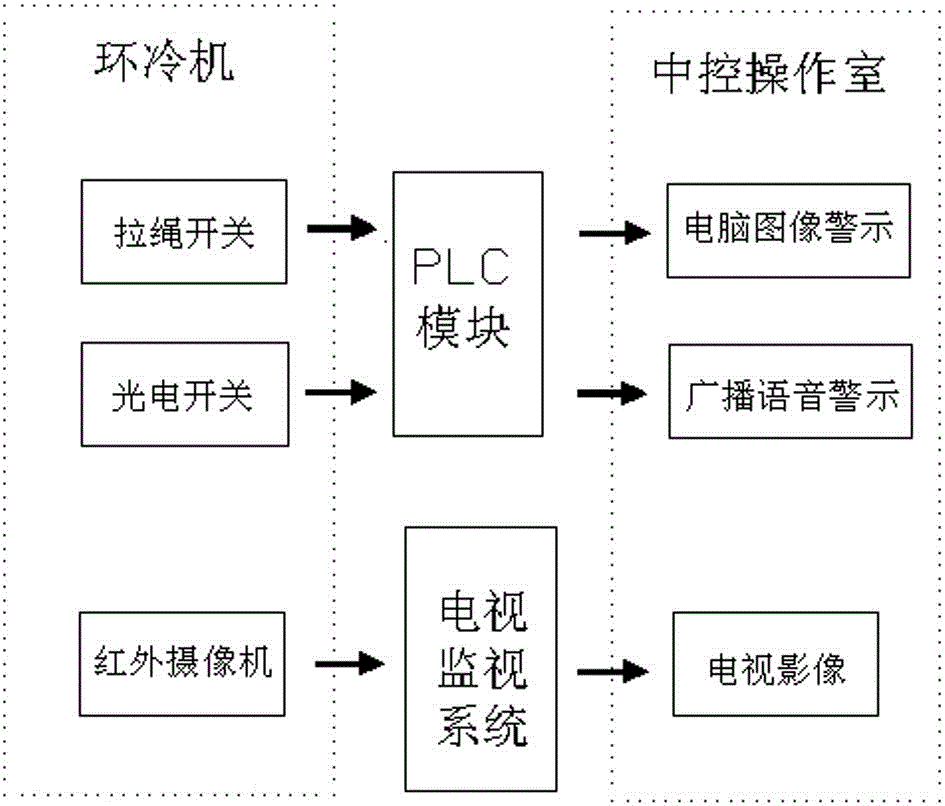

[0014] see figure 2 ,A sort of The warning system for wheel shedding of sintering ring cooling machine, including The photoelectric switch 2, rope switch and infrared camera 3 next to the trolley 4 of the ring cooler, wherein the photoelectric switch 2 and the rope switch are connected to the PLC module, and the PLC module is written according to the signal sent by the photoelectric switch 2 and the rope switch The corresponding program is sent to the computer and radio in the hollow operating room for computer picture warning and broadcast voice warning, and the infrared camera 3 is connected with the TV monitoring system, and the signal is transmitted to the TV by the TV monitoring system to be displayed as a TV image.

[0015] The trolley 4 of the annular cooler has two left and right trolley wheels 5 , and the trolley wheels 5 are located on two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com