Combined vacuum contactor

A vacuum contactor and combined technology, applied in pull-out switch cabinets, switchgears, electrical components, etc., can solve the problems of inconvenient maintenance, expansion of accidents, poor anti-misoperation, etc., and achieve convenient maintenance and maintenance. The effect of preventing the expansion of accidents and improving the prevention of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

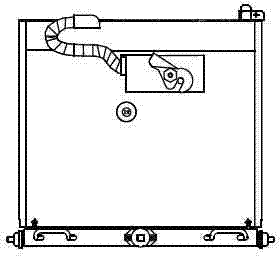

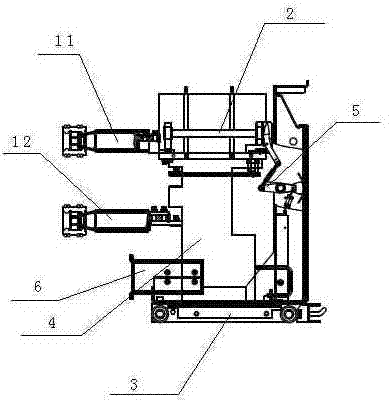

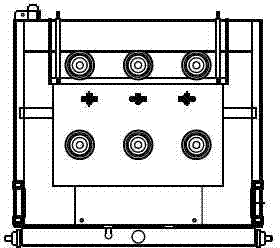

[0024] figure 1 The left view of the vacuum contactor provided by the embodiment of the present invention; figure 2 The front view of the vacuum contactor provided by the embodiment of the present invention; image 3 The right side view of the vacuum contactor provided by the embodiment of the present invention is shown in the figure: the combined vacuum contactor provided by the present invention includes a chassis handcart 3 installed in the switch cabinet, a decoupling mechanism 5, a vacuum contactor 4 and The fuse 2 on the upper end surface of the vacuum contactor; the vacuum contactor 4 is set on the chassis handcart 3; the vacuum contactor 4 is movably connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com