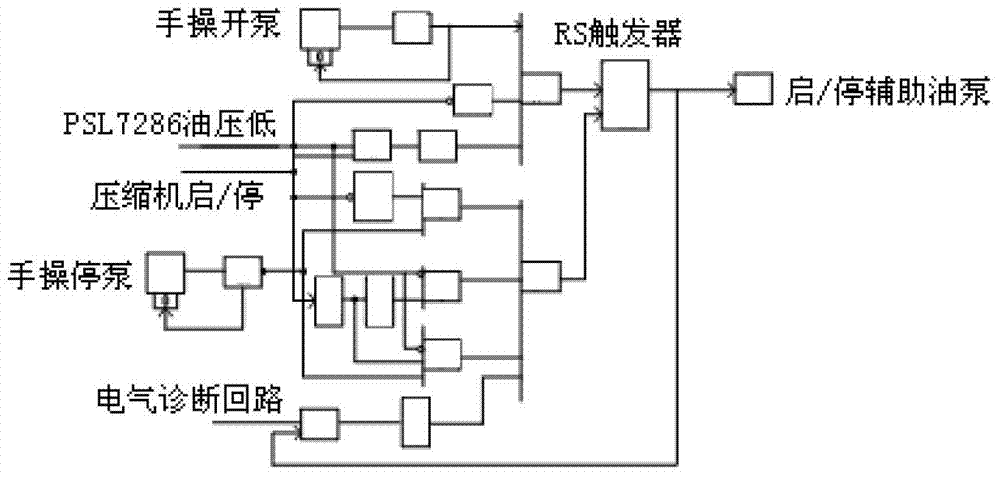

Control circuit of turbocompressor oil system

A technology for controlling circuits and compressor oil, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., it can solve the problems of time lag, failure to achieve self-starting of auxiliary oil pumps, fluctuations in lubricating oil pressure system, etc., and achieve standardized start and stop. Operation, increase the manual start/stop function, avoid accidental stop or the effect of accident enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to ensure the long-term safe operation of the compressor, the control circuit of the present invention realizes the intelligent self-starting function of the oil system, and the main purpose is to regulate the oil system of the turbine compressor under various operating modes of the turbine compressor. Start-stop operation, and in abnormal or faulty state, the interlock system can act timely and accurately and handle emergency accidents instead of operators, so as to ensure equipment and personal safety, effectively handle faults, and avoid accidental parking or accident expansion.

[0014] The present invention first collects the compressor start-stop signal of the main oil pump and the low pressure signal of the oil pump; when the oil system is in normal circulation, the control circuit controls the auxiliary oil pump to stop automatically when the main oil pump is running and there is no low oil pressure alarm; when the main oil pump of the compressor is norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com